An intelligent mechanical system fault diagnosis method based on multi-level multi-mode feature extraction

A feature extraction and system fault technology, applied in the field of multi-level and multi-mode intelligent mechanical system fault diagnosis, can solve the problems of low identification of mechanical fault diagnosis, single fault signal characteristic parameters, etc., to enhance robustness and timeliness, The effect of increasing fault tolerance and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

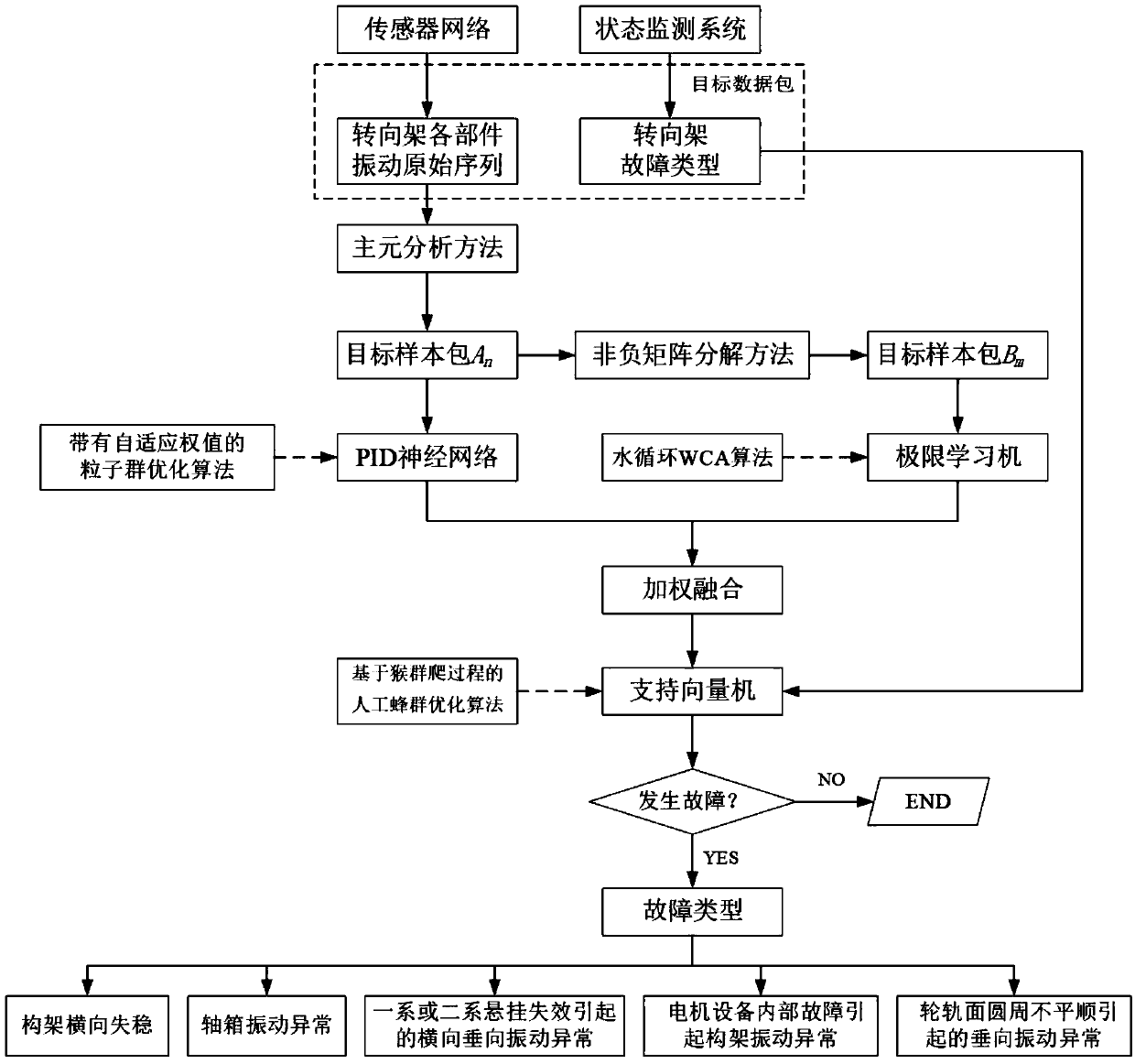

[0075] The multi-level multi-mode feature extraction intelligent mechanical system fault diagnosis method provided in this embodiment uses training samples to train PID neural network, extreme learning machine and support vector machine, and obtains the original vibration sequence of each part of the bogie through the sensor network, Judging the failure type of mechanical parts, the mechanical parts in this embodiment specifically refer to the parts of the train bogie, and the specific method of the present invention is as follows: figure 1 shown, including the following steps.

[0076] Step 1, obtain the original vibration sequence of the mechanical part.

[0077] Real-time acquisition of relevant operating condition parameters, that is, operating condition characteristics related to the fault type, through the sensor network arranged by each component of the target mechanical system, to obtain the original vibration sequence of each component of the bogie, and the acquisitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com