Permanent magnet fault-tolerant motor based on alternate tooth winding and unequal stator pitch

A permanent magnet fault-tolerant, stator tooth technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of difficult phase isolation design of motors, and achieve increased short-circuit current suppression ability and magnetic field weakening ability, short-circuit current suppression ability and The effect of enhanced field weakening capability, increased torque density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

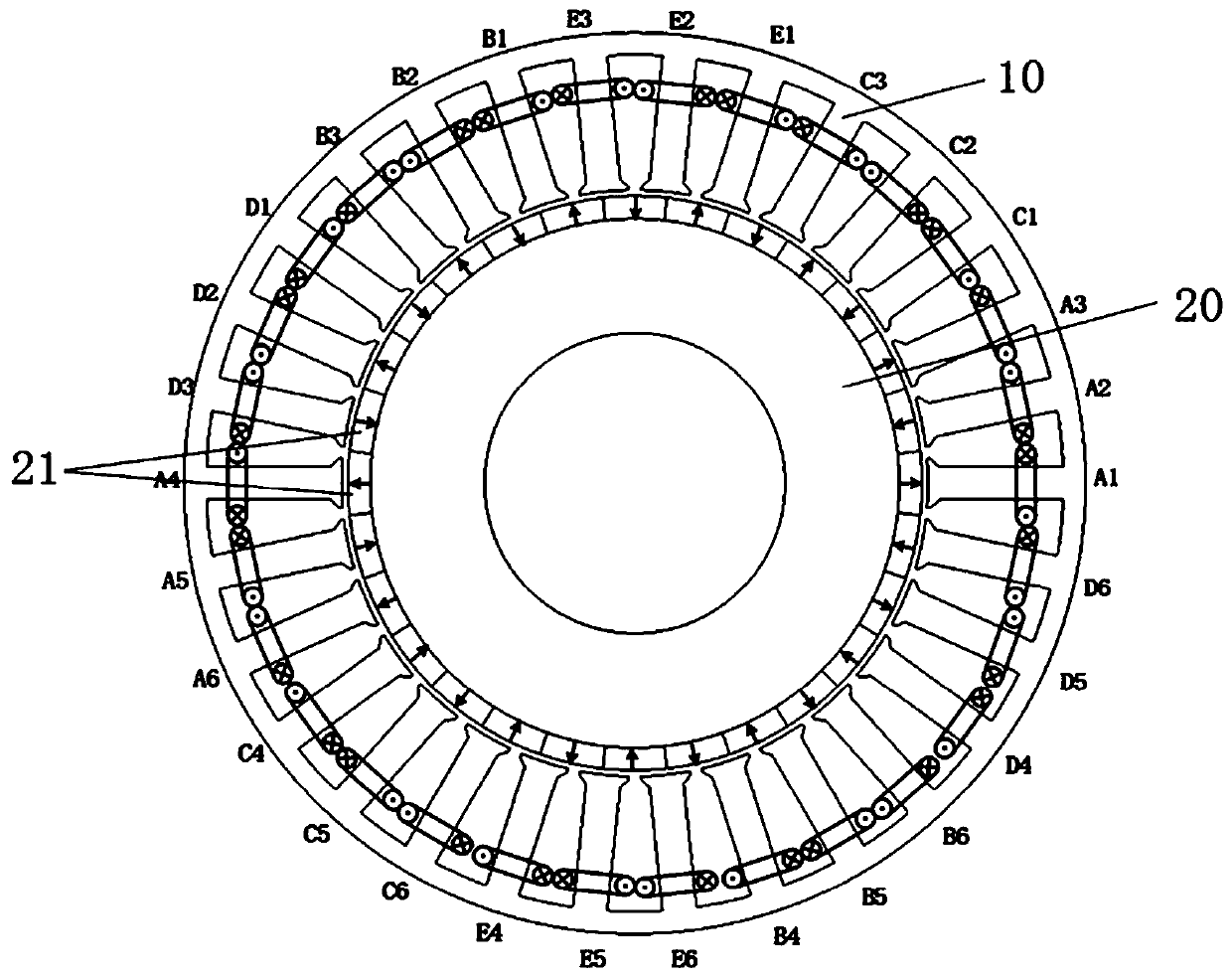

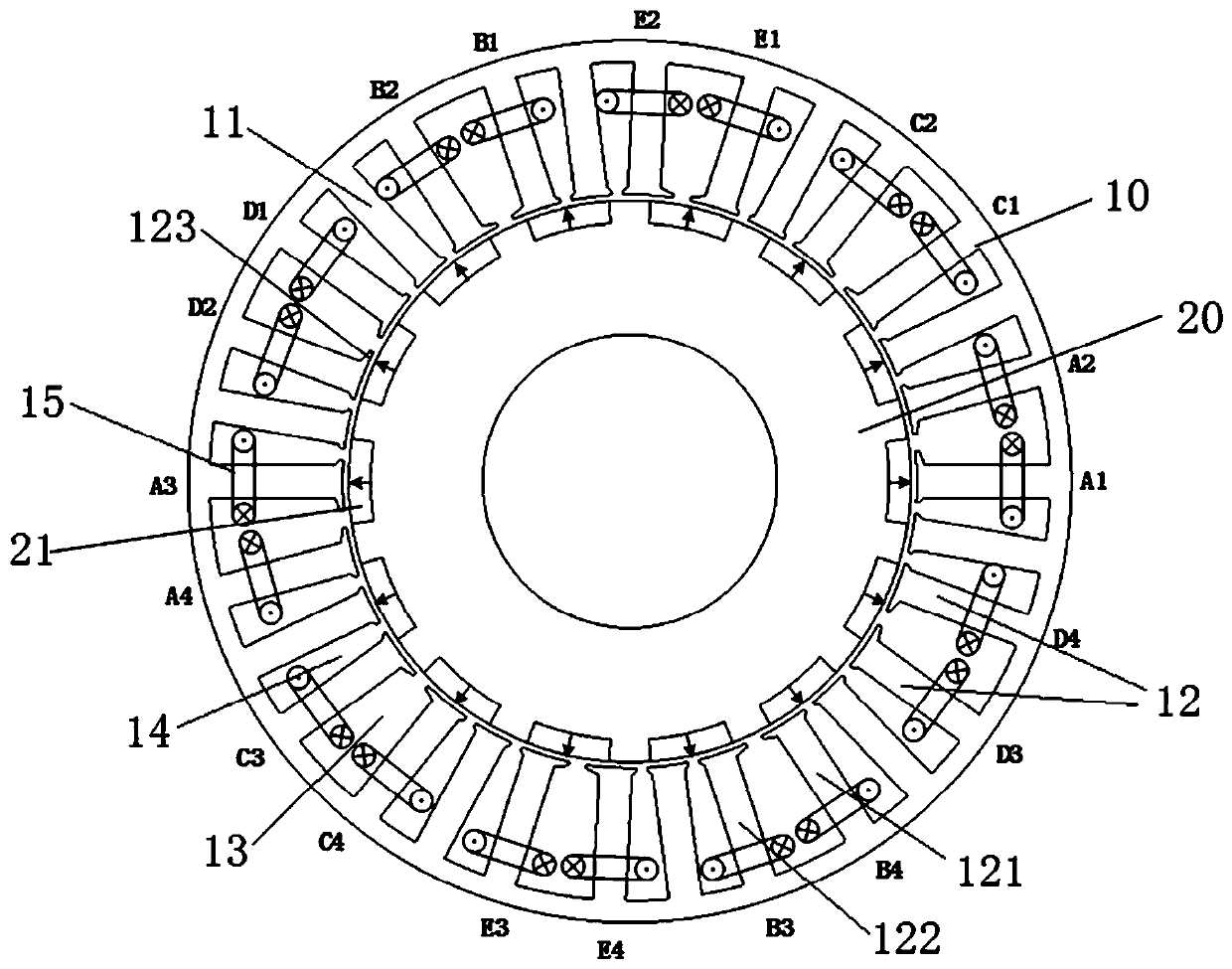

[0028] Embodiment 1 Inner rotor motor

[0029] like figure 2 As shown, a permanent magnet fault-tolerant motor based on alternate-tooth windings and unequal stator pitches includes a stator 10 and a rotor 20 coaxially set, and the stator is set on the outer periphery of the rotor.

[0030] The pole-slot coordination of the permanent magnet fault-tolerant motor satisfies Ns'=2p'±1, where Ns'=Ns / t, p'=p / t, Ns is the number of stator slots, p is the number of rotor pole pairs, and t is Ns and p greatest common divisor of . like figure 2 For the 30-slot 28-pole motor shown, t=2, Ns=30, p=14. In addition, such as 9-slot 8-pole motor (t=1) and so on.

[0031] The stator has Ns / 3 fault-tolerant teeth 11 and 2Ns / 3 armature teeth 12, and the Ns / 3 fault-tolerant teeth are uniformly arranged along the inner circumference of the stator. exist figure 2 , with 10 fault-tolerant teeth and 20 armature teeth.

[0032] Two armature teeth are arranged between two adjacent fault-toleran...

Embodiment 2

[0047] Embodiment 2 Outer rotor motor

[0048] The rotor is coaxially sleeved on the outer circumference of the stator, and Ns / 3 fault-tolerant teeth are evenly arranged along the outer circumference of the stator, and the rest of the structure is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com