Medical instrument rapid cleaning device

A technology for cleaning devices and medical devices, applied in the field of medical devices, can solve the problems of inconvenient use, time-consuming, and incomplete killing of cleaning and disinfection equipment, and achieve the effect of fast killing speed, short time-consuming, and thorough killing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

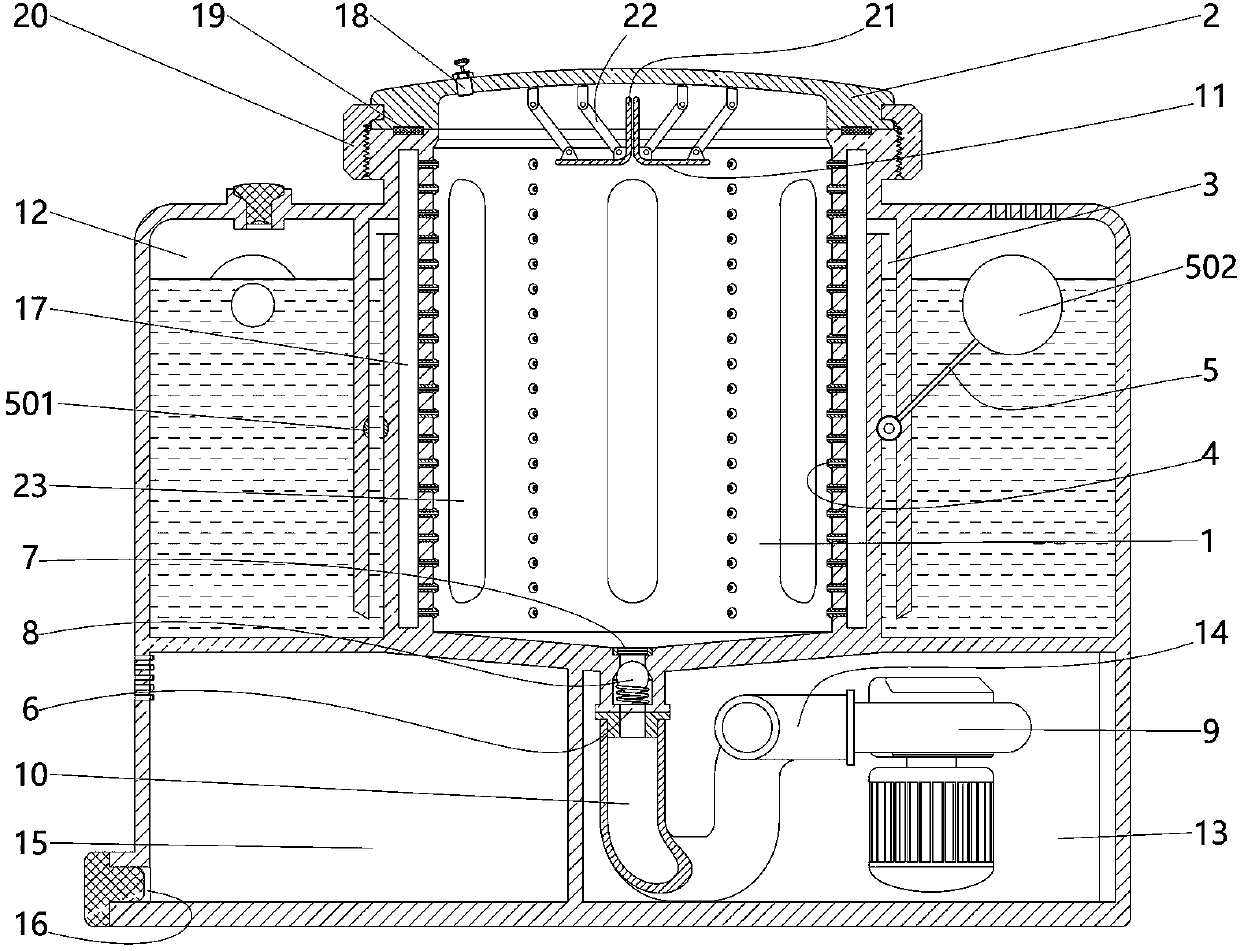

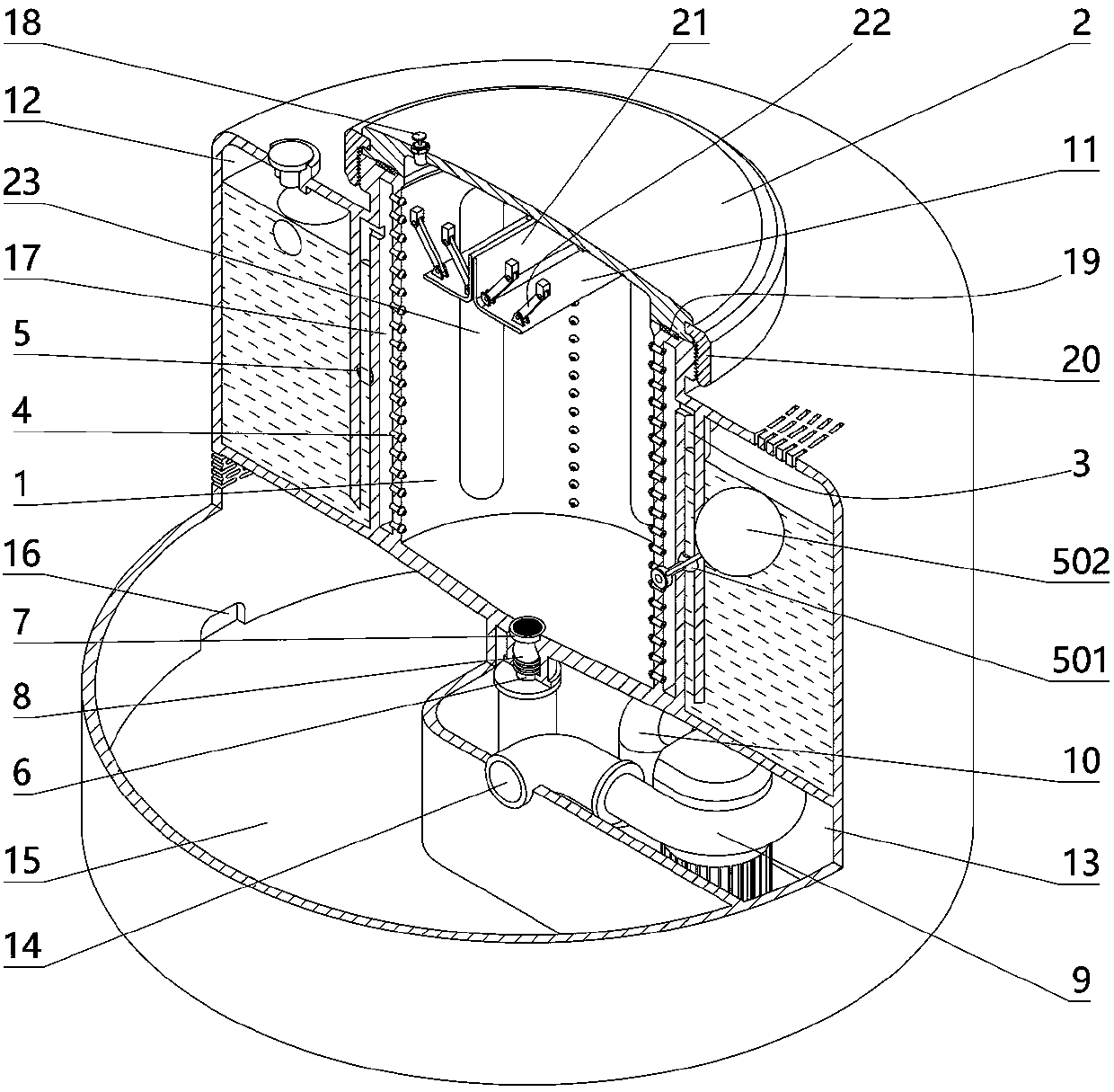

[0009] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] Depend on Figure 1 to Figure 2 Provided, the present invention includes a vertically arranged cleaning container 1 and a container cover 2 for sealing the cleaning container 1, said cleaning container 1 has at least one vertically arranged suction channel 3 placed on the periphery of the cleaning container 1, On the wall of the cleaning container 1 there are a number of nozzles 4 facing the inside of the cleaning container 1 and evenly distributed on the wall of the cleaning container 1. The nozzles 4 communicate with the upper part of the suction channel 3 through pipelines; The ball valve 5 and the spool 501 of the float valve 5 are placed in the suction channel 3 and placed below the connection between the nozzle 4 and the suction channel 3, and are used to control the on-off of the fluid entering the nozzle 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com