Grid tray part machining method

A processing method and grid plate technology are applied in the processing field of grid plate parts, which can solve the problems of high machining accuracy and surface roughness requirements of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

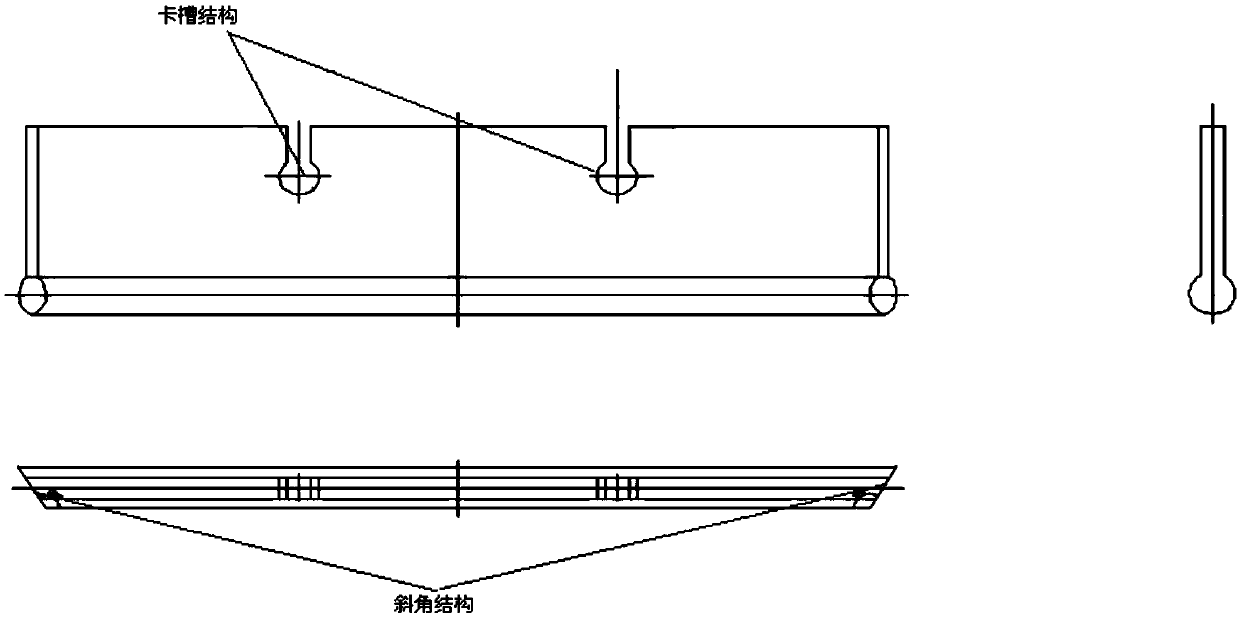

[0016] Such as figure 1 Shown is the part diagram of the grid plate, according to the requirements of the shape and size accuracy of the grid plate, and the surface roughness requirements, the present invention adopts the wire cutting method to complete the processing. Grid plate processing is divided into shape cutting, slot cutting and bevel cutting. The shape processing adopts wire cutting processing to complete the processing of the elongated thin plate with a match head shape.

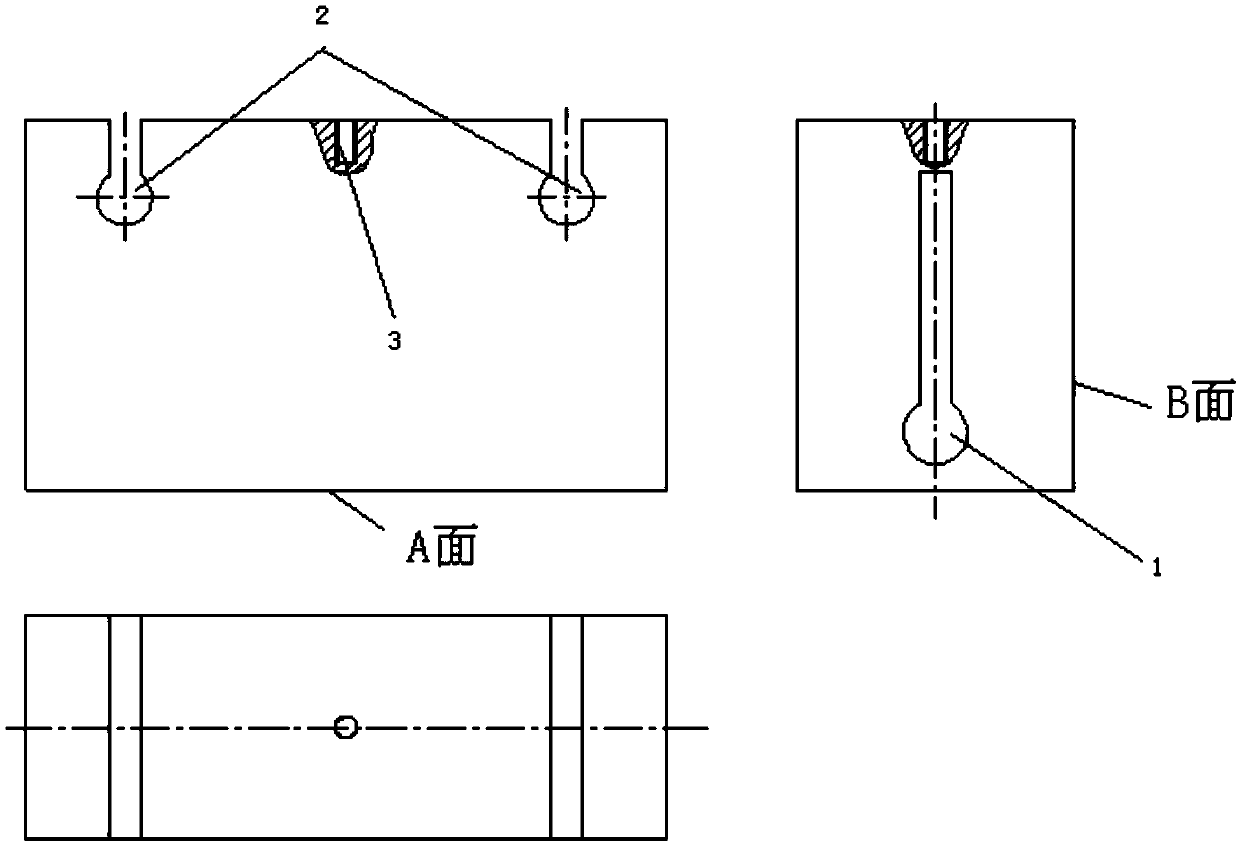

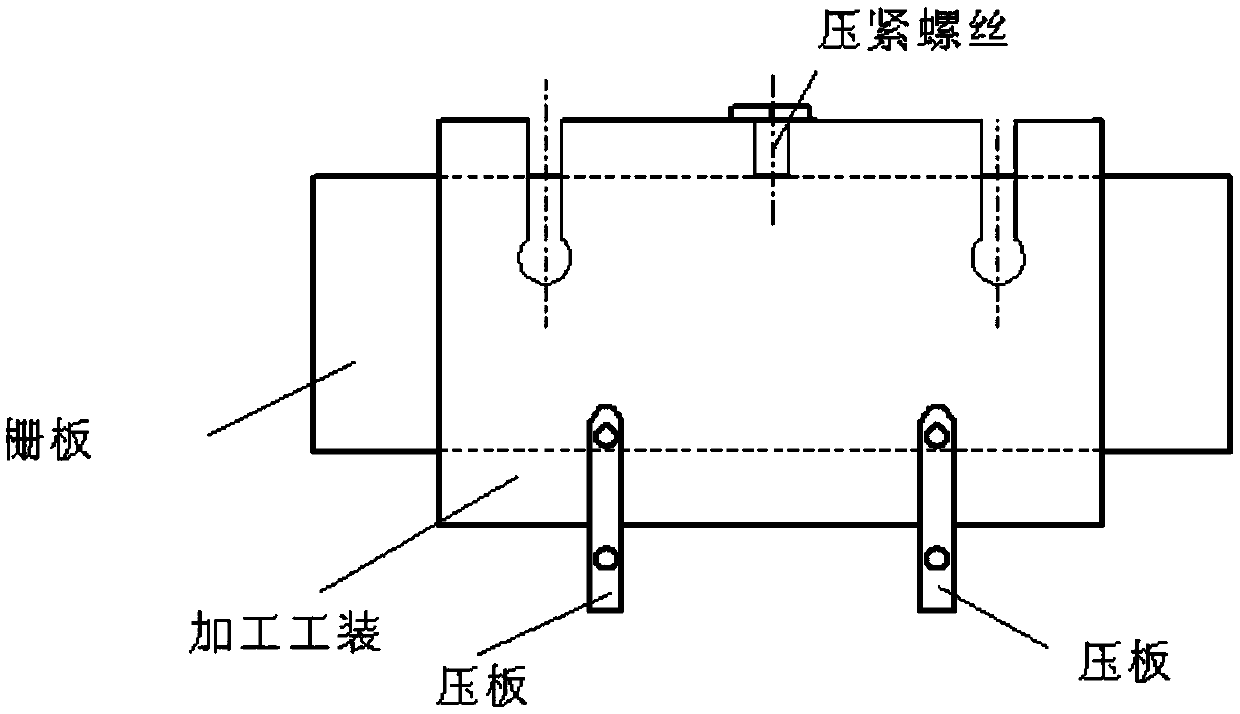

[0017] Card slot and bevel processing tooling design: stainless steel material, design and processing as follows figure 2 tooling to realize wire cutting processing of slots and bevels. The overall shape of the tooling is a cuboid, with a matchhead-shaped through groove running through the front and back, that is, groove B2, and a matchhead-shaped groove A1 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com