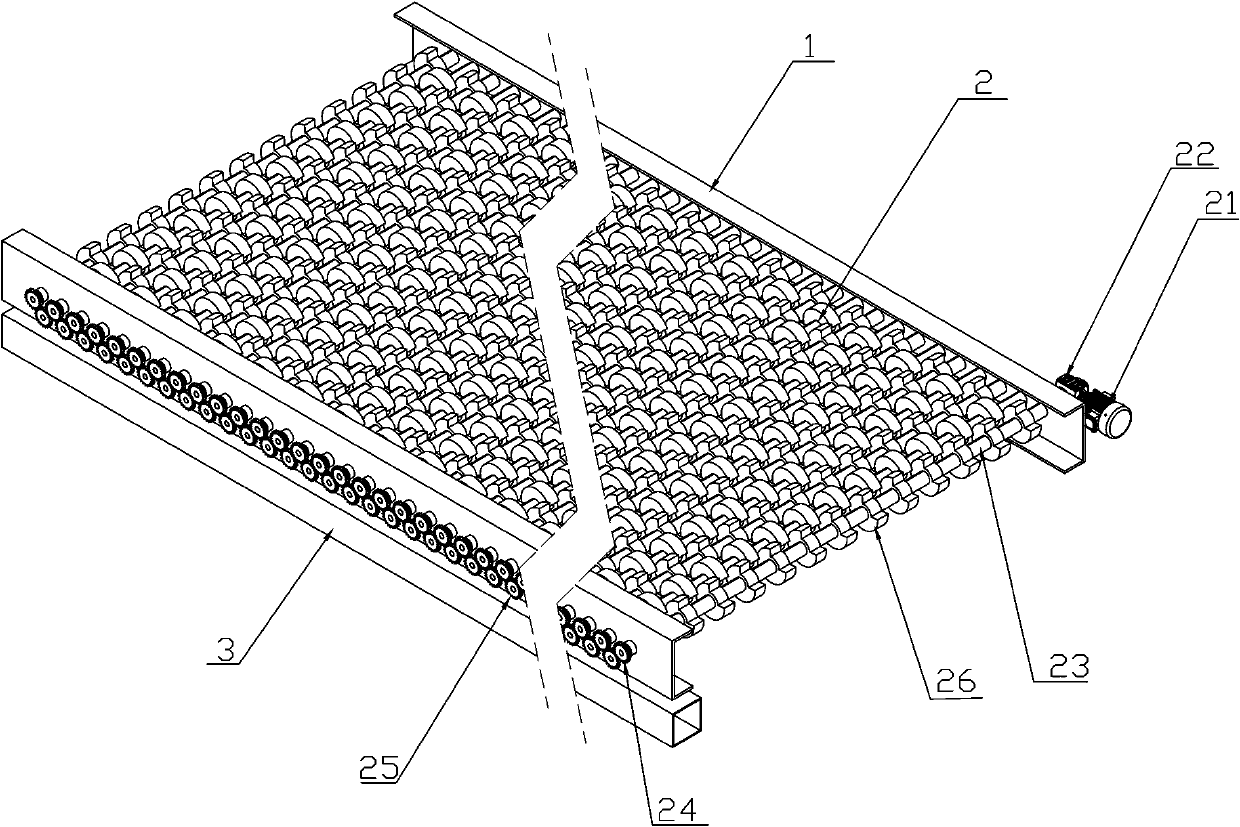

Cutting platform for roller type laser cutting machine

A laser cutting machine and cutting platform technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as damage, low efficiency, and complex structure, and achieve improved automation control, improved work efficiency, and high transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The drive motor is fixedly installed on the main body of the platform, and its output shaft is connected to the reducer, and the output shaft of the reducer is connected to the transmission shaft. The transmission shafts are multiple, and drive gears are installed at both ends of each transmission shaft. There are multiple supporting rollers, which are installed on the transmission shaft according to fixed intervals, and play the role of supporting and conveying the plates. The transmission shafts are installed on the main body of the platform through the transmission shaft installation holes in turn, and the reversing gears pass through the The reversing gear mounting hole is installed on the main body of the platform, and a reversing gear is matched between each driving gear so that all transmission shafts rotate in the same direction. The installation position of the driving gear and the reversing gear is on the outside of the side wall of the platform main body , the...

Embodiment 2

[0035] The support rollers are three-quarter circles, and the installation angles of the support rollers installed on each drive shaft are opposite to the support rollers installed on the adjacent drive shafts. Due to the large number of support rollers, during the cutting process Damage will gradually occur, especially the damage rate of the support rollers in the middle cutting machine processing area of the cutting platform will be slightly higher. To replace the support rollers in the middle, it needs to be removed from the outside and inside, and then installed back in sequence after replacement, which is time-consuming and laborious. It will also cause Unnecessary waste, the support roller is designed as a three-quarter circle structure, and its quarter opening can be used as a movable and detachable connection, so that any support roller that needs to be replaced can be replaced separately. The installation angle of the supporting rollers installed on the adjacent dr...

Embodiment 3

[0037] The shaft diameter of the drive shaft is the same as that of the main shaft of the uncoiling leveler, the drive motor is a servo motor, and the servo motor is electrically connected to the frequency conversion controller. The synchronization of loading and unloading of the platform is better. The uncoiling straightening machine conveys the straightened coiled sheet to the cutting platform. The transmission mechanism of the cutting platform runs, and the supporting roller rolls to cover the processing area with the sheet to be processed, and the cutting machine performs cutting. After the processing is completed, the transmission mechanism will transfer the processed parts to the unloading area. At the same time, the loading link from the uncoiling straightening machine to the cutting platform is repeated. The use of servo motors and frequency conversion controllers makes the automation degree Higher, which greatly improves the production efficiency of the laser cutting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com