Manufacturing method of integral bent lap joint type frame

A manufacturing method and overall technology, applied in the direction of electrical components, circuits, battery pack parts, etc., can solve the problems of high processing cost, increased processing cost, large number of tooling fixtures, etc., and achieve less man-hours, easy processing, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

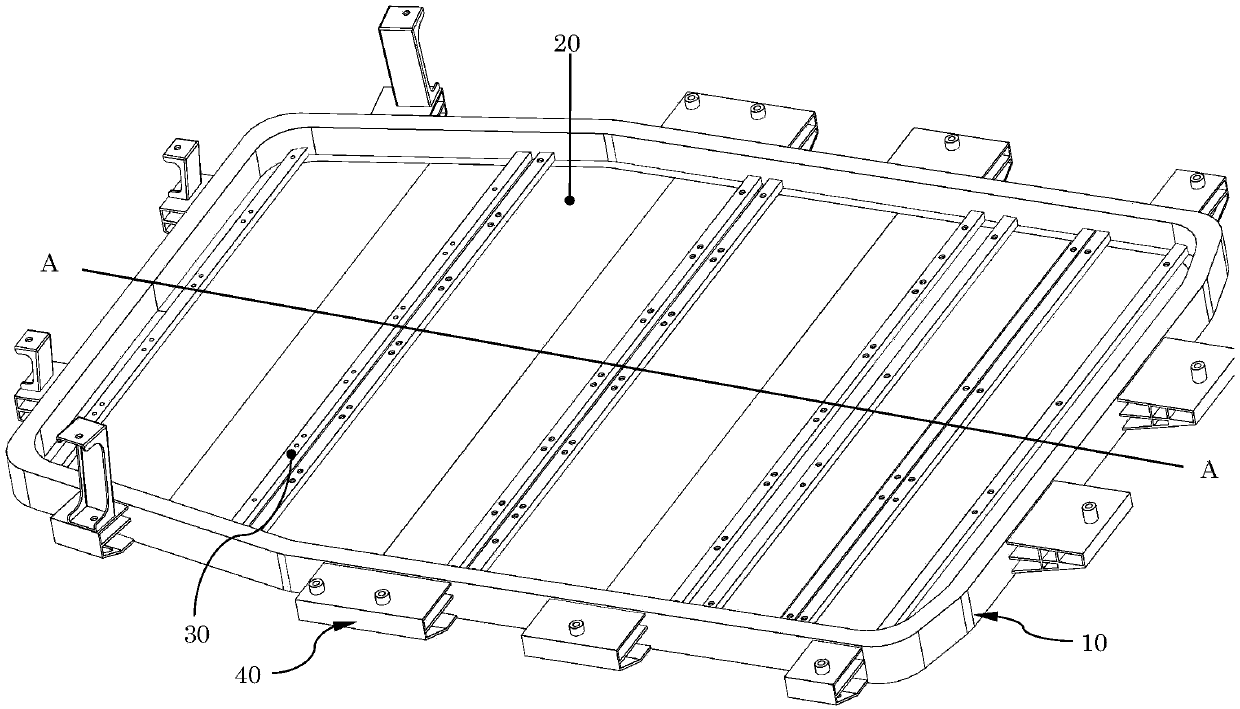

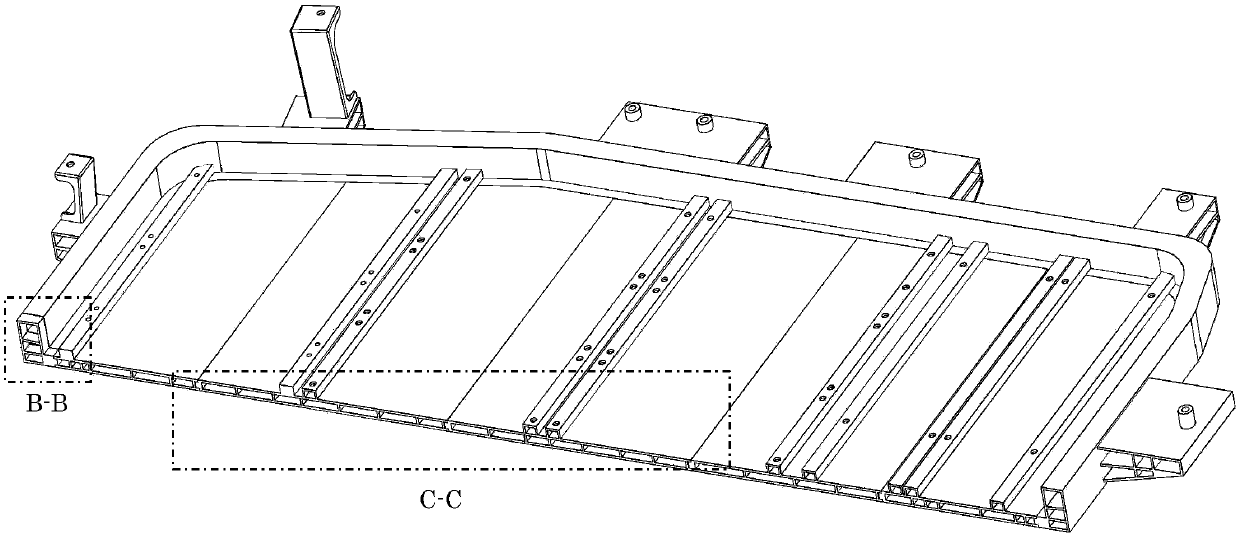

[0058] Such as figure 1 , 2 As shown in , 3, the overall bending and overlapping frame includes:

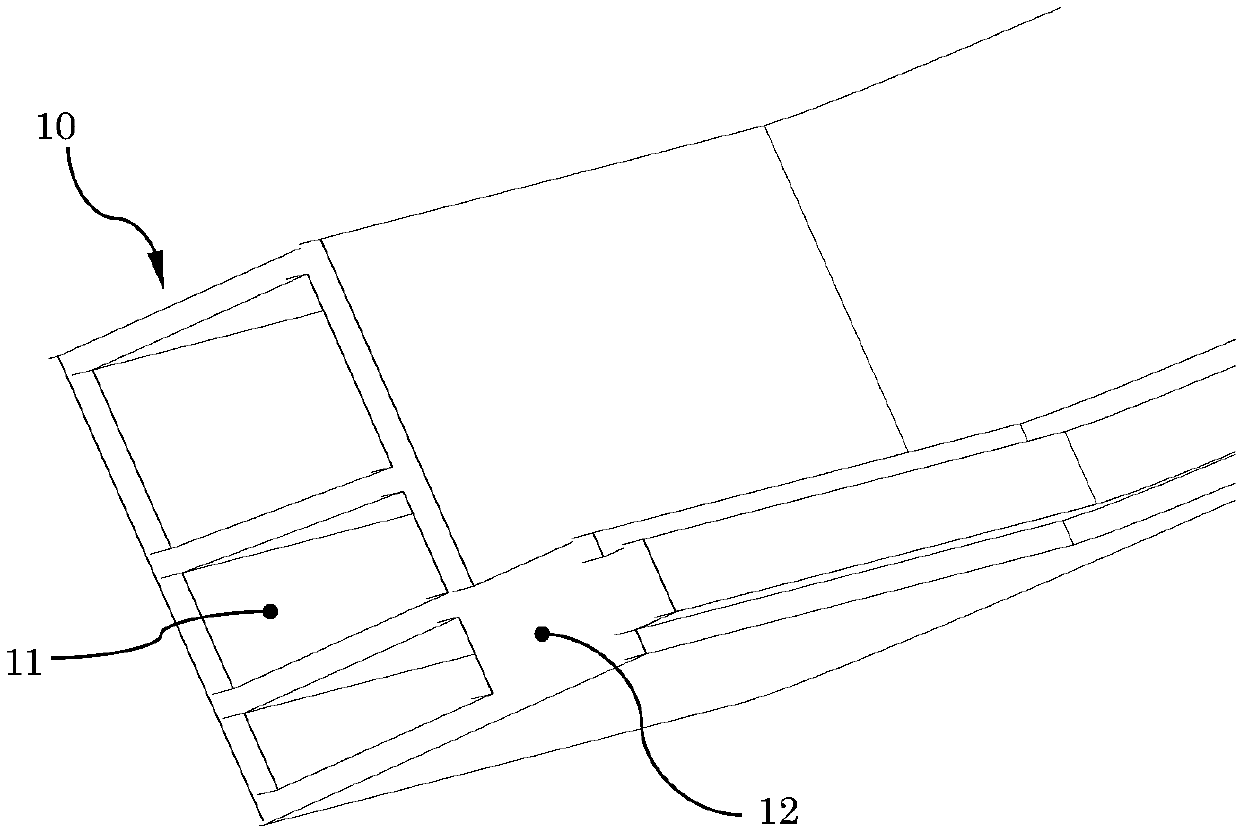

[0059] The ring beam assembly 10 is a closed ring formed by bending and connecting ring beam profiles.

[0060] The bottom plate 20 is snapped into the ring beam assembly.

[0061] The support rod 30 is used to connect and fix the bottom plate on the ring beam assembly.

[0062] The method for making the above frame includes the following steps:

[0063] Step 1, processing the predetermined length of the ring beam profile into an unconnected closed ring;

[0064] Step 2. Stretch the unconnected and closed circle, and insert the bottom plate;

[0065] Step 3: Connect and fix the parts near both ends of the support rod with the ring beam profile, and connect the middle part of the two ends with the bottom plate, so that the bottom plate is connected and fixed by the support rod in the above-mentioned unconnected closed circle;

[0066] Step 4. Close the unconnected closed cir...

Embodiment 2

[0068] As an optimized operation, the fourth step of closing the unconnected closed circle and connecting includes the following operations:

[0069] Fix the ends of the unconnected loops on the two welding heads of the resistance welding machine, and apply pressure to close the welded connection.

[0070]In this embodiment, a resistance welding machine is used, preferably a spot welding machine. Fix the two spot welding arms of the spot welding machine to the two ends of the unconnected ring, and then pressurize and energize to complete the welding.

Embodiment 3

[0072] Further, in order to better ensure that the butt joint is accurate during welding and no deflection occurs, on the basis of Example 2, the two ends of the unconnected rings are inserted into the positioning sleeve during operation, and the two unconnected rings are pressurized so that the two unconnected The ends are aligned exactly. The positioning sleeve is in the shape of a tube, which just fits the ring beam profile, so under the constraint of the ring beam profile positioning sleeve, warping caused by thermal deformation is not easy to occur during welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com