Device and method for clearing burrs on circular saw blade base body

A technology for cleaning equipment and circular saw blades, which is applied in the direction of metal sawing equipment, metal processing equipment, grinding/polishing equipment, etc., and can solve the difficulty in cleaning the substrate burrs of multi-specification circular saw blades, and the impossibility of cleaning the upper and lower surfaces of the substrate , Time-consuming and labor-intensive handling, etc., to avoid mismatching process beats, convenient and quick removal, and fast transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

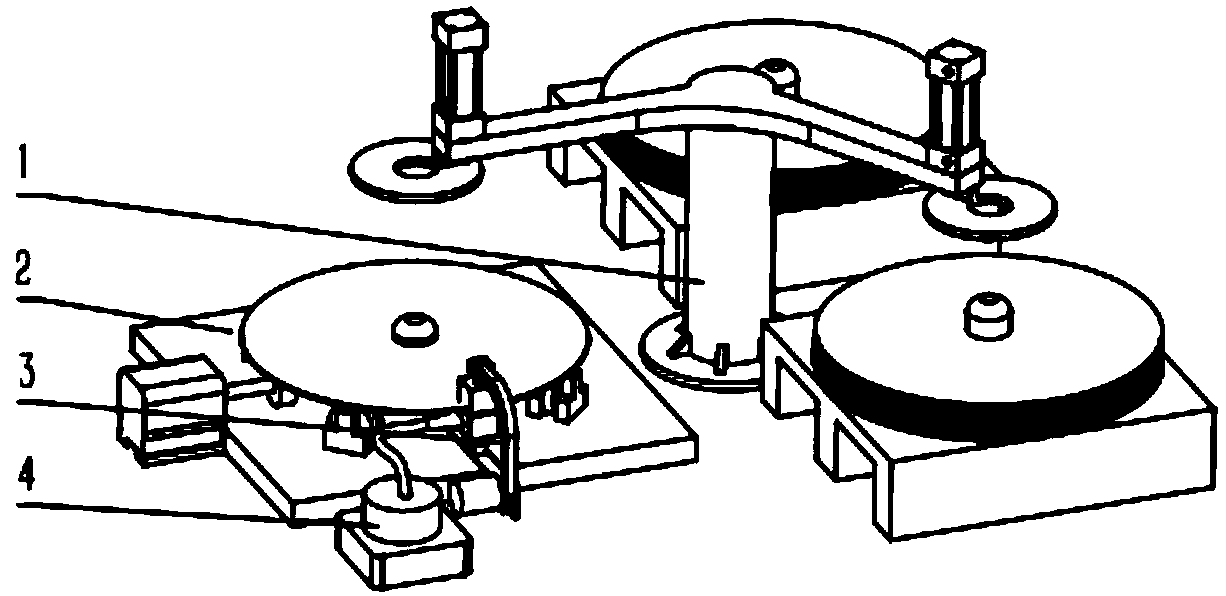

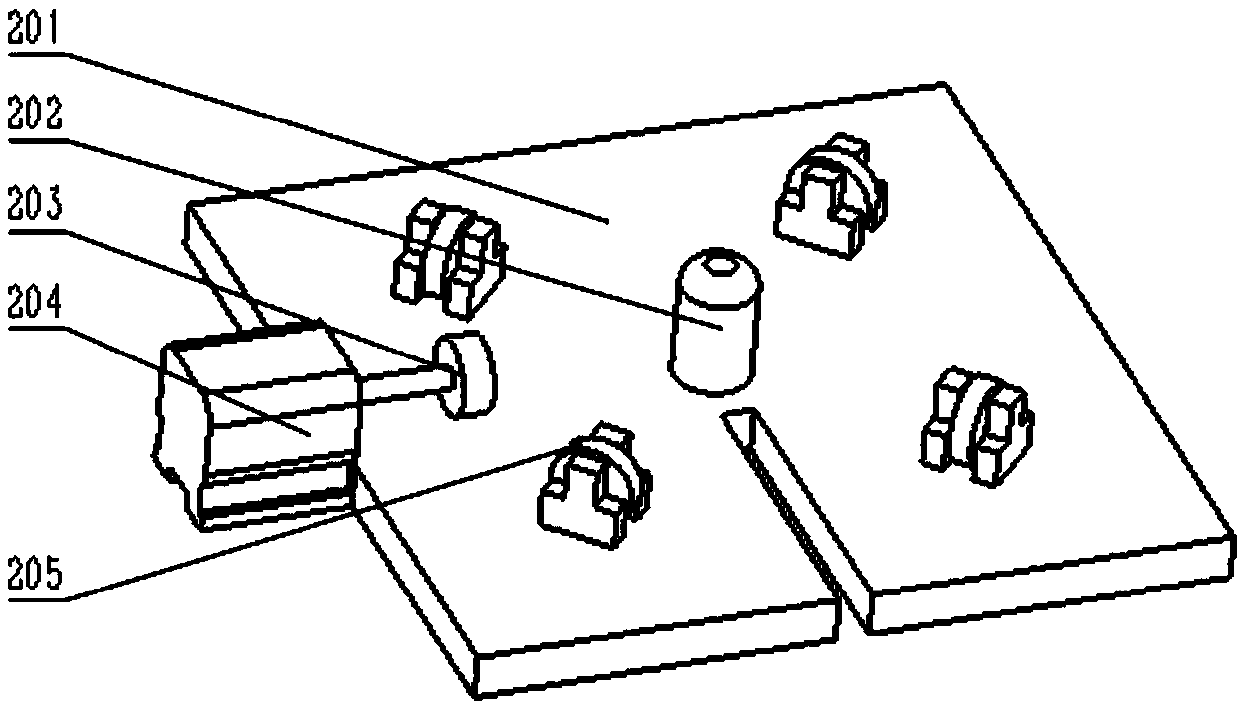

[0046] Example 1, such as Figure 1-4 As shown, a circular saw blade substrate burr cleaning equipment includes a storage device, an automatic loading and unloading device 1 arranged on one side of the storage device, a transmission device 2, a grinding device 3 arranged on one side of the transmission device 2, and a post-processing device 4 .

[0047] The storage device is used to place the saw blade, and the saw blade includes a saw blade to be processed and a processed saw blade; the automatic loading and unloading device is used to realize the position conversion of the saw blade between the storage device and the transmission device; the The transmission device 2 is used to drive the saw blade to be processed to rotate along its own axis; the grinding mold in the grinding device 3 can closely fit the substrate of the saw blade to be processed, and the grinding device 3 is used to clean the burr of the saw blade substrate; The post-processing device 4 is used to collect ...

Embodiment 2

[0063] Embodiment 2, this embodiment utilizes the circular saw blade substrate deburring equipment in embodiment 1, and discloses a circular saw blade substrate deburring method, including the following steps,

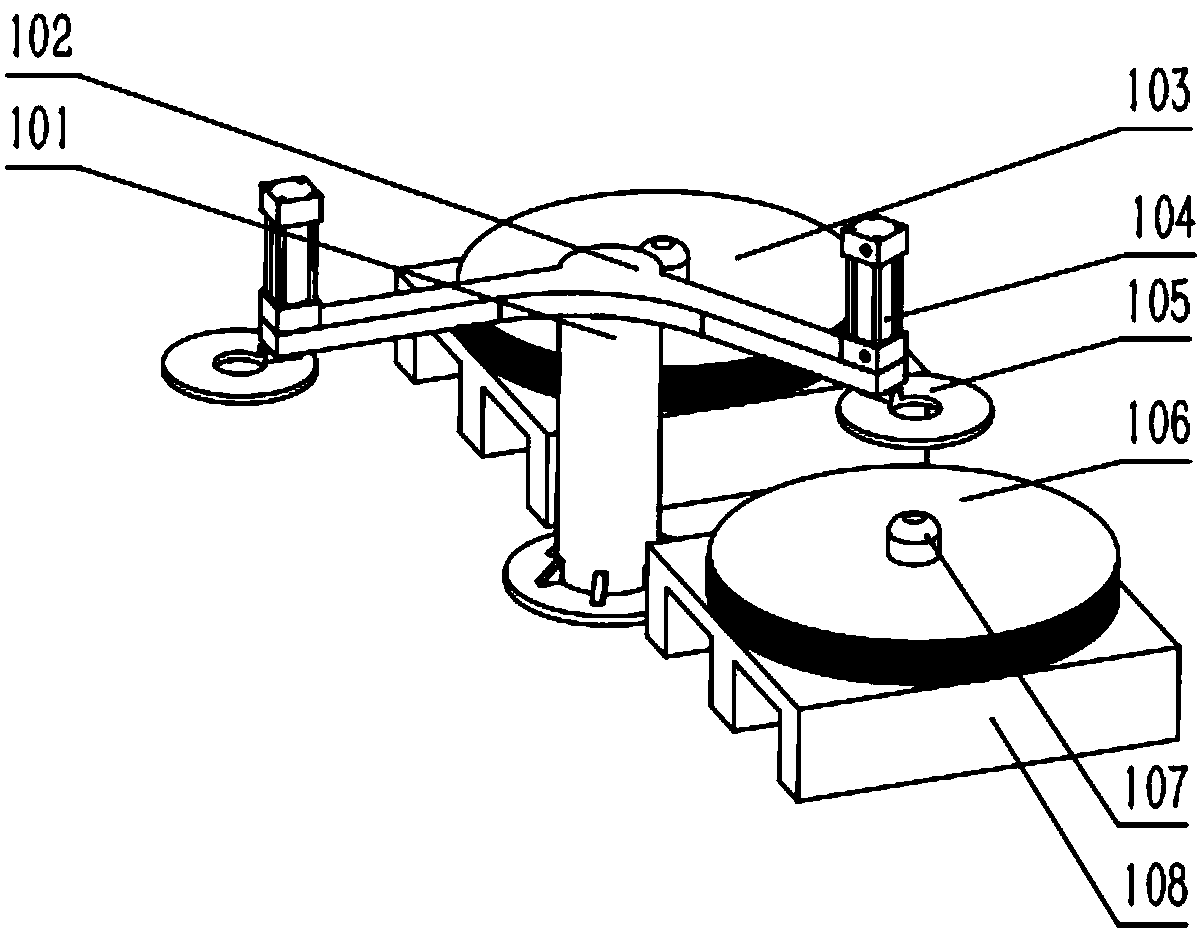

[0064] Step 1, the saw blades to be processed are stacked and placed in the loading storage device, and the through holes of the saw blades to be processed pass through the positioning shaft 107 of the tray 108;

[0065] Step 2, use the driving device to drive the column 101 to rotate, so that the adsorption mechanisms at both ends of the frame 102 are respectively aligned with the feeding storage device and the conveying device, and then the linear feeding mechanism 104 drives the adsorption mechanism to descend, and the adsorption mechanism respectively absorbs the processed saw blade and For the saw blade to be processed, the linear feed mechanism 104 reversely moves to drive the adsorption mechanism and the adsorbed saw blade to rise;

[0066] Step 3, the driving d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap