Anti-shaking rope sawing machine, and method for preventing diamond rope from shaking by using anti-shaking rope sawing machine

A technology of diamond wire and wire saw machine, which is applied to stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of eccentric grinding of diamond rope and no problem of output power, and achieve the effect of preventing eccentric grinding of beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

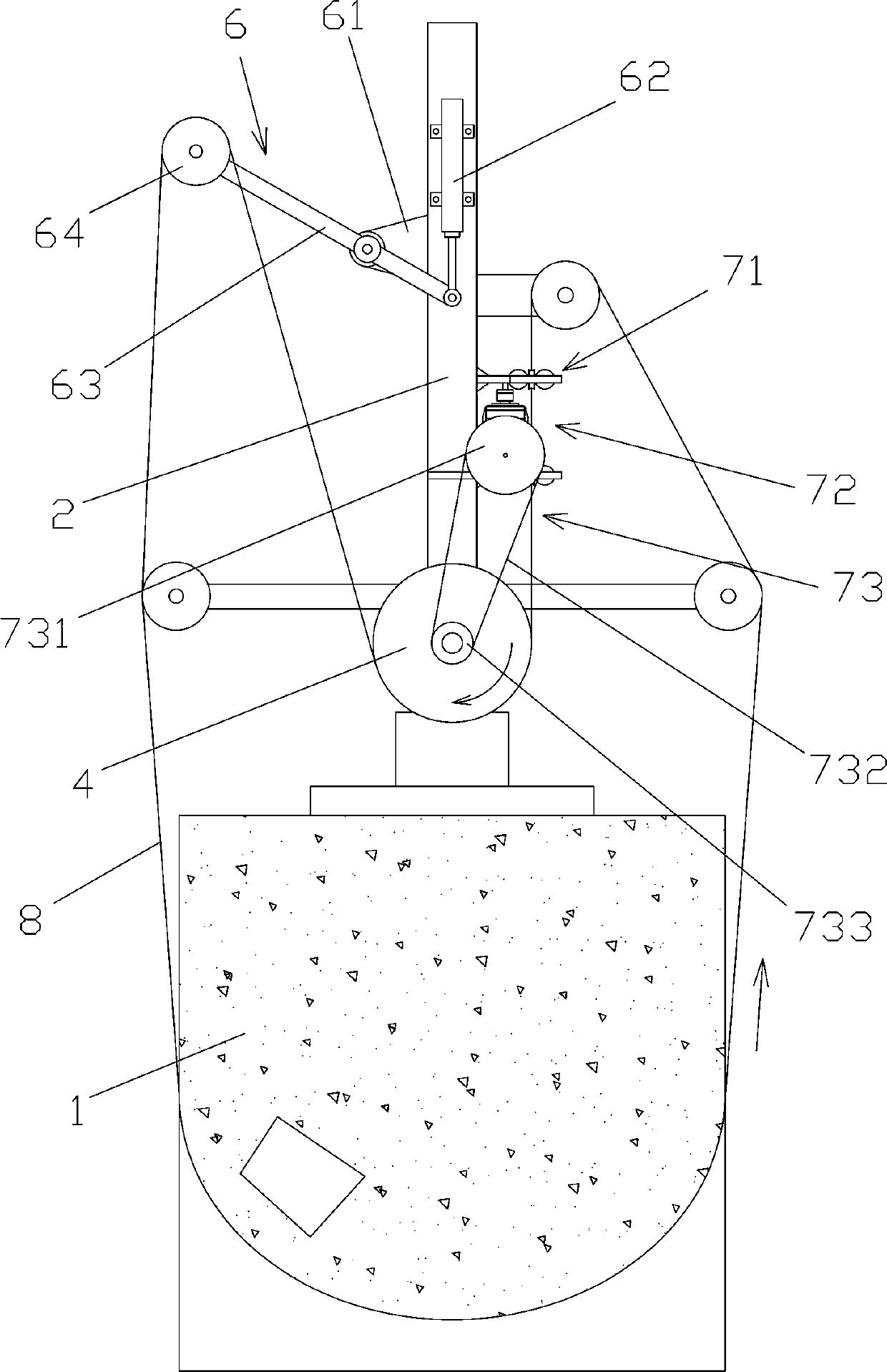

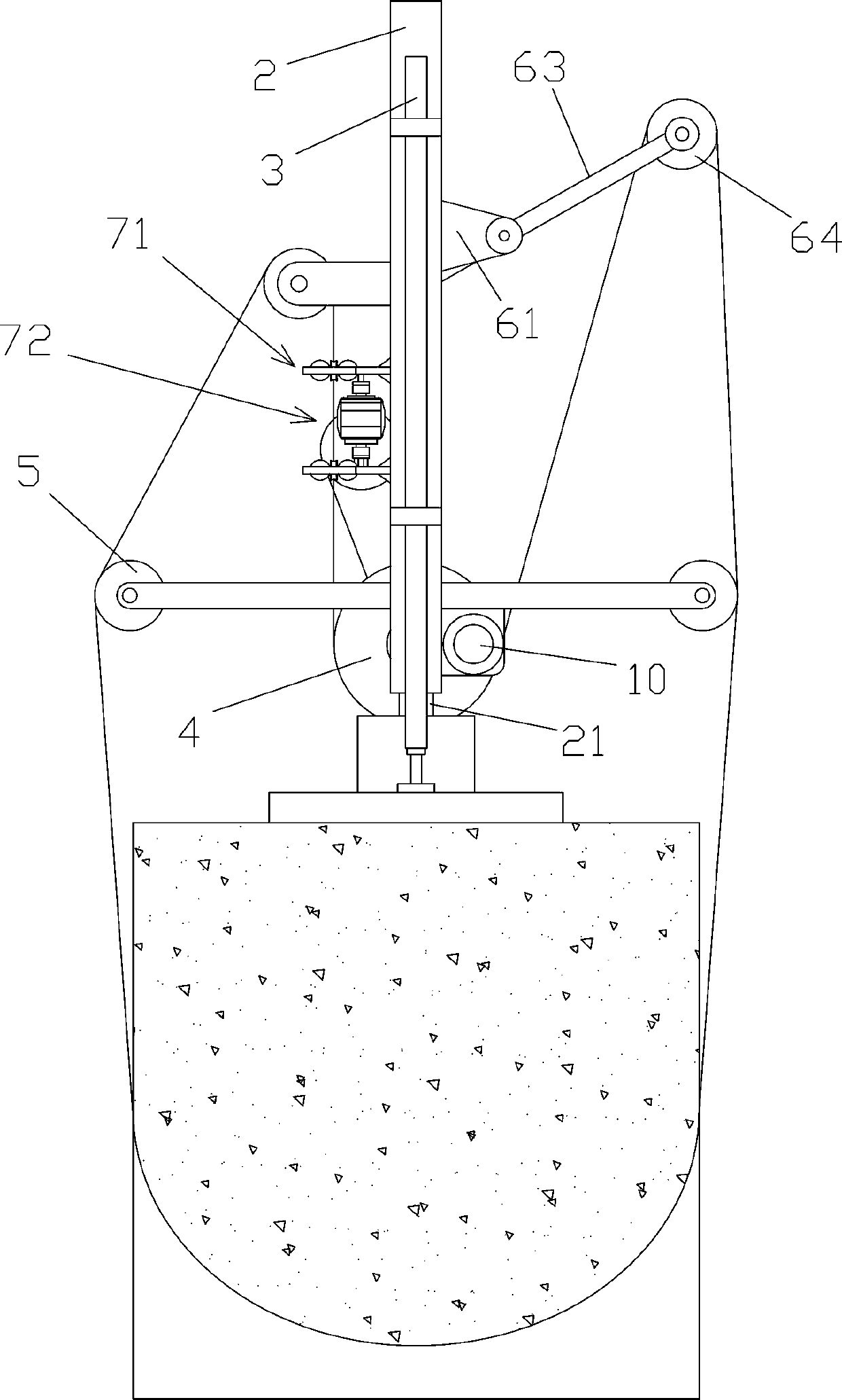

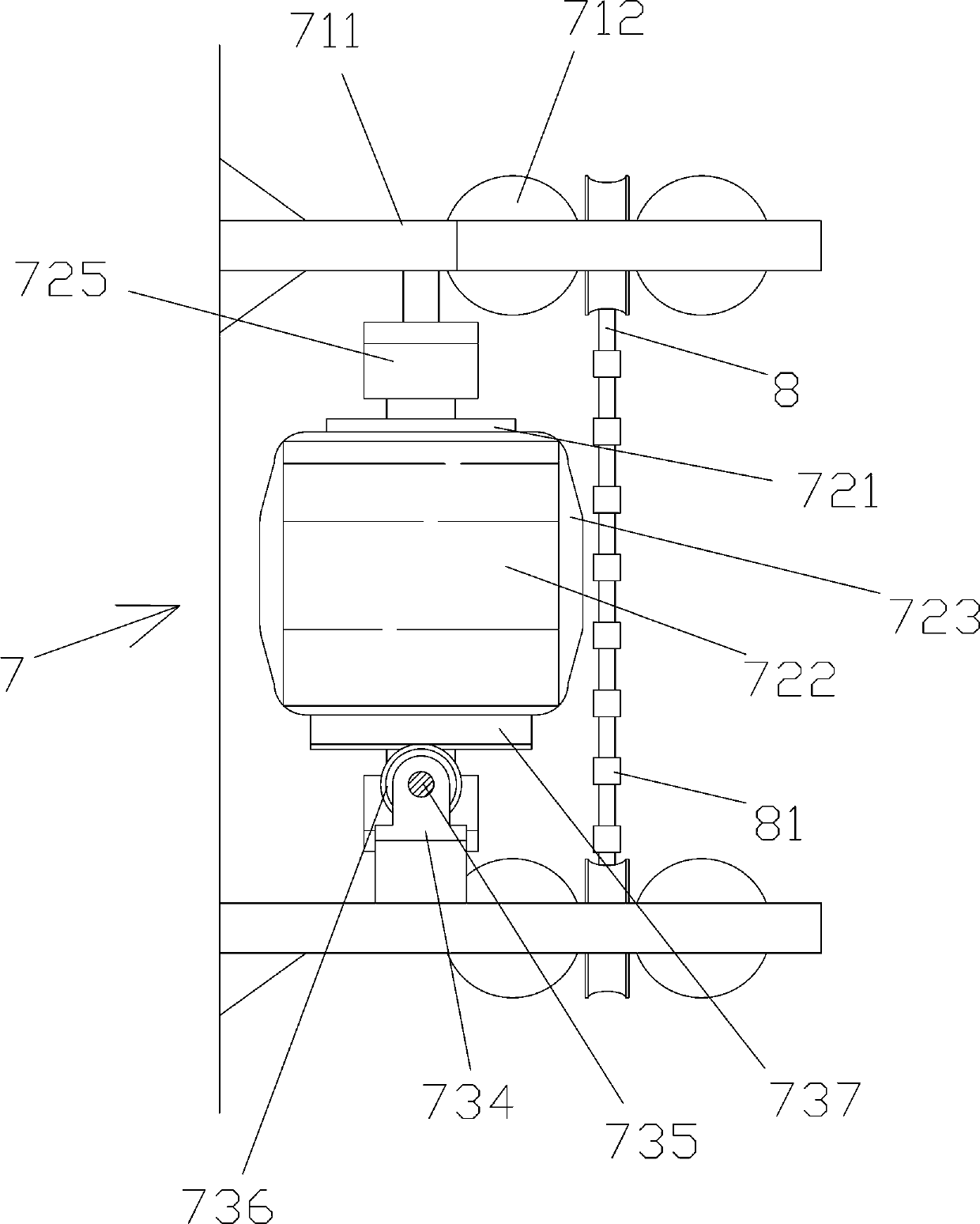

[0028] Such as Figures 1 to 5 As shown, the anti-shake wire saw machine includes a frame, a guide rail 21, a feed cylinder 3 and a plurality of guide wheels 5, a sliding sleeve 2 is installed outside the guide rail 21, and a hydraulic motor 10 is installed on the sliding sleeve 2, and the hydraulic motor 10 The output shaft is connected with the driving wheel 4, and also includes a control system 9 and a tension mechanism 6 installed on the sliding sleeve 2;

[0029] The tensioning mechanism 6 includes a fork 63, a support 61 fixedly connected to the sliding sleeve 2, and a tensioning oil cylinder 62. The piston rod of the tight oil cylinder 62 is hinged, the diamond rope 8 of the wire saw machine is lapped on the traction wheel 64, and the traction wheel 64 is located at the output side of the wire saw machine; figure 1 The middle drive wheel 4 rotates clockwise, the diamond rope 8 enters from the left side of the drive wheel 4, and outputs from the right side. The steel wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com