Processing method of material level in high-level silo for steelmaking

A processing method and high material level technology, applied in packaging, large containers, conveyor objects, etc., can solve problems such as large uncertainties and errors, insufficient feeding or laying, affecting converter production, etc., to improve accuracy , Improve production efficiency, avoid insufficient feeding and the effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

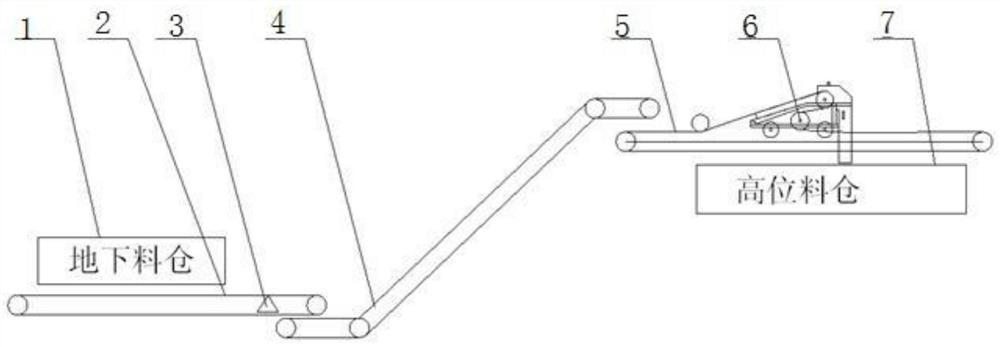

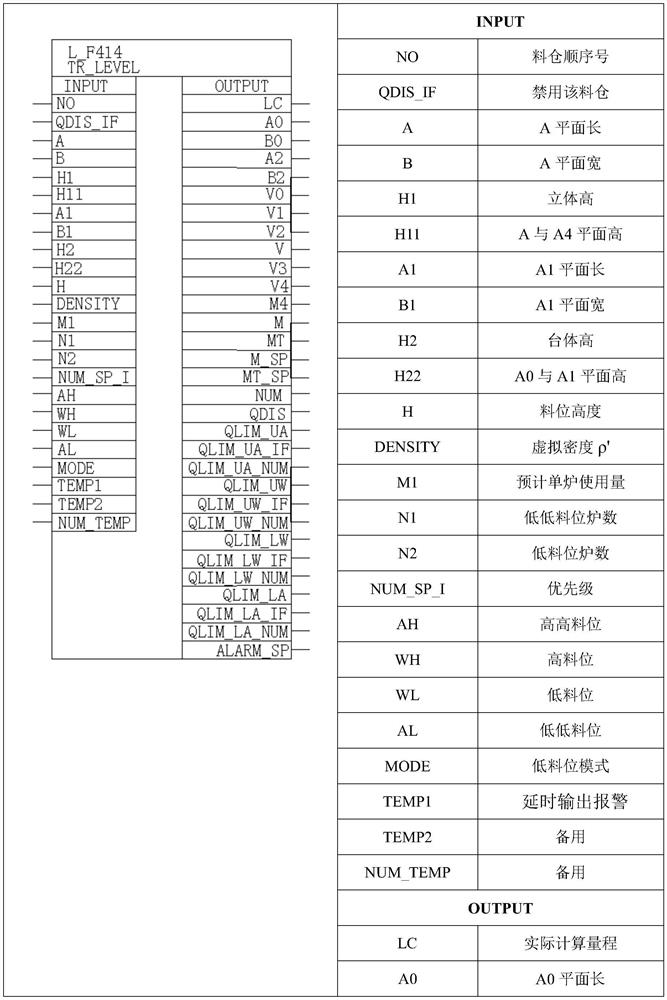

[0122] Embodiment 1: see Figure 1-Figure 5 , a method for processing the material level of a steelmaking high-level silo, the processing method comprising the following steps: 1) calculating the volume of the silo;

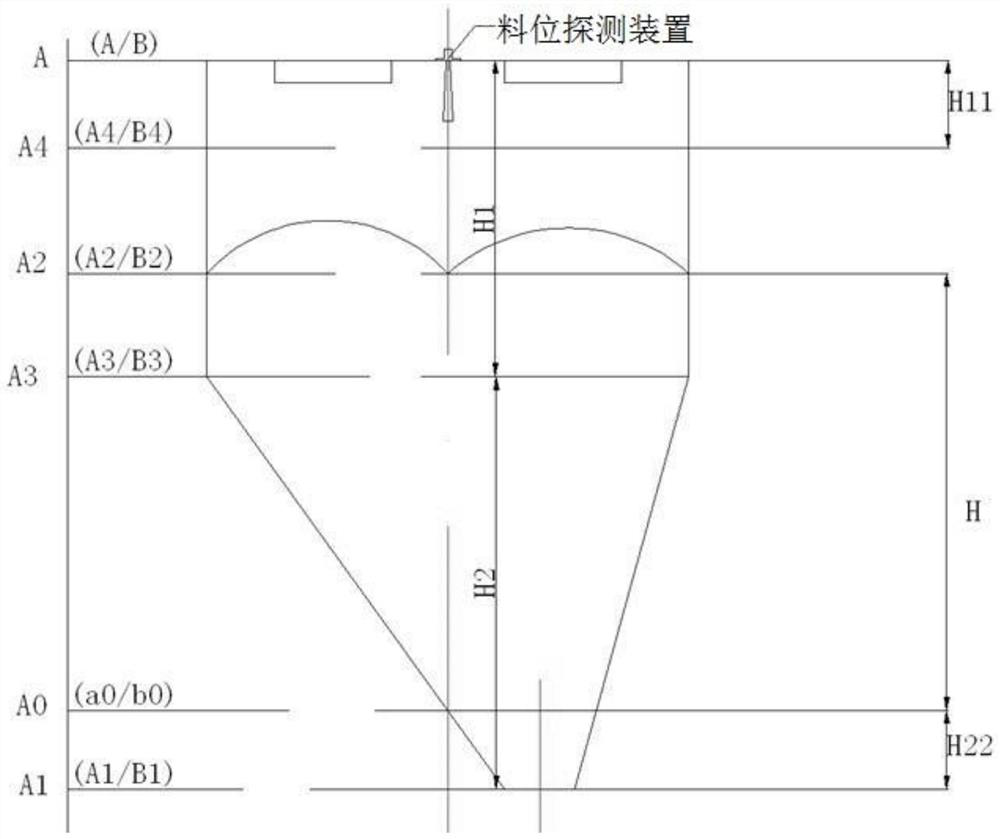

[0123] Since the highest point of the material level is the position of the discharge port, it is not suitable to install the material level detection device. Generally, it is selected at a position slightly away from the discharge port to detect the lower material, so as to avoid the vibration during discharge from affecting the accuracy of the material level detection device. , Also avoid damage to the material level detection device when stacking.

[0124] According to the shape of the silo, the silo is divided into an upper cube and a lower platform. As shown in the figure, the silo is divided into 6 planes, which are A, A0, A1, A2, A3, and A4 planes. The A0 plane is the set material level O plane, and the A2 plane is the material level detection device. Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com