High-speed hot cutter slitting device and control method thereof

A high-speed, hot-knife technology, applied in the control field of high-speed hot-knife slitting device and high-speed hot-knife slitting device, can solve the problems of long adjustment time, low efficiency, low precision, etc., achieve good dynamic balance effect and shorten movement distance, effects that improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

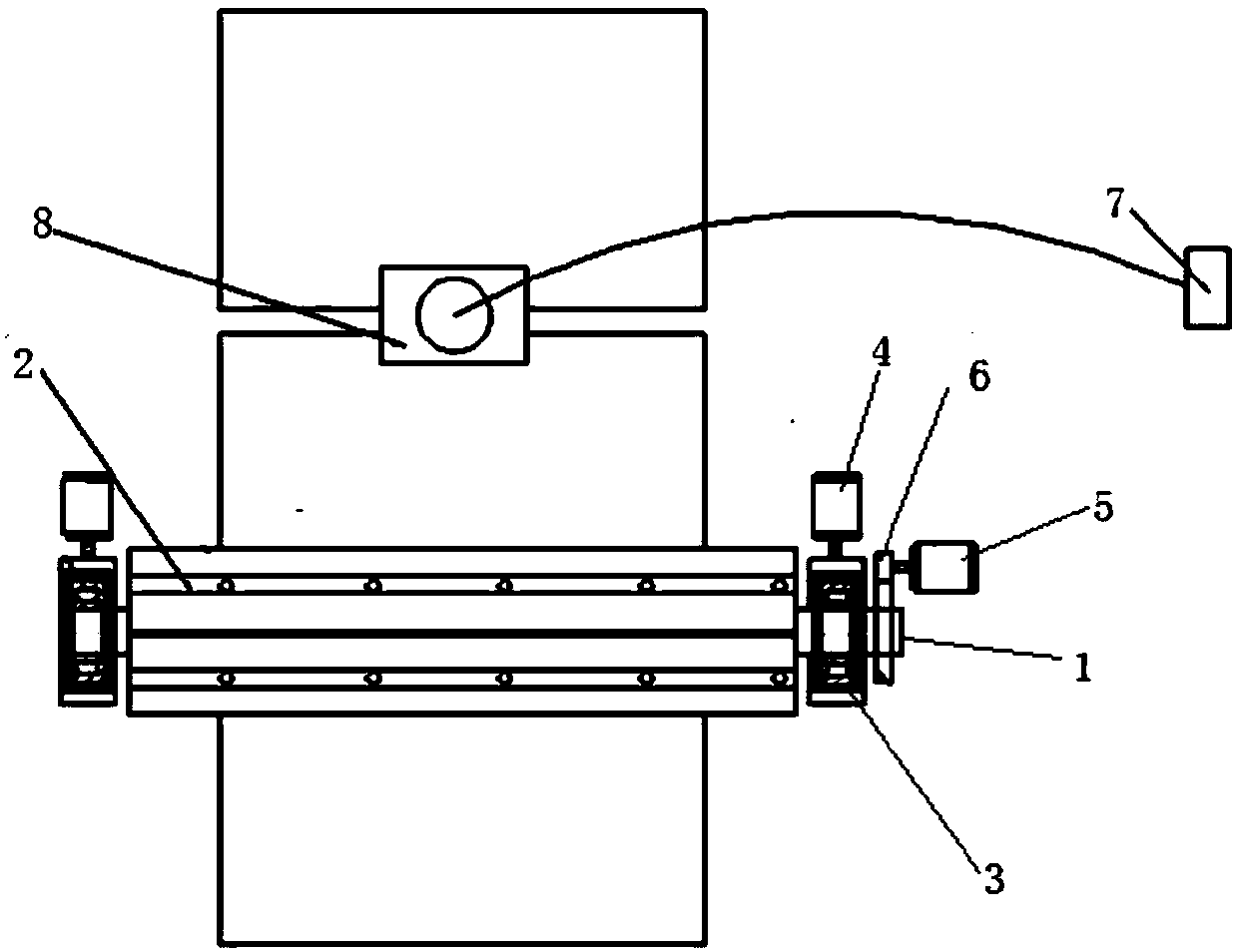

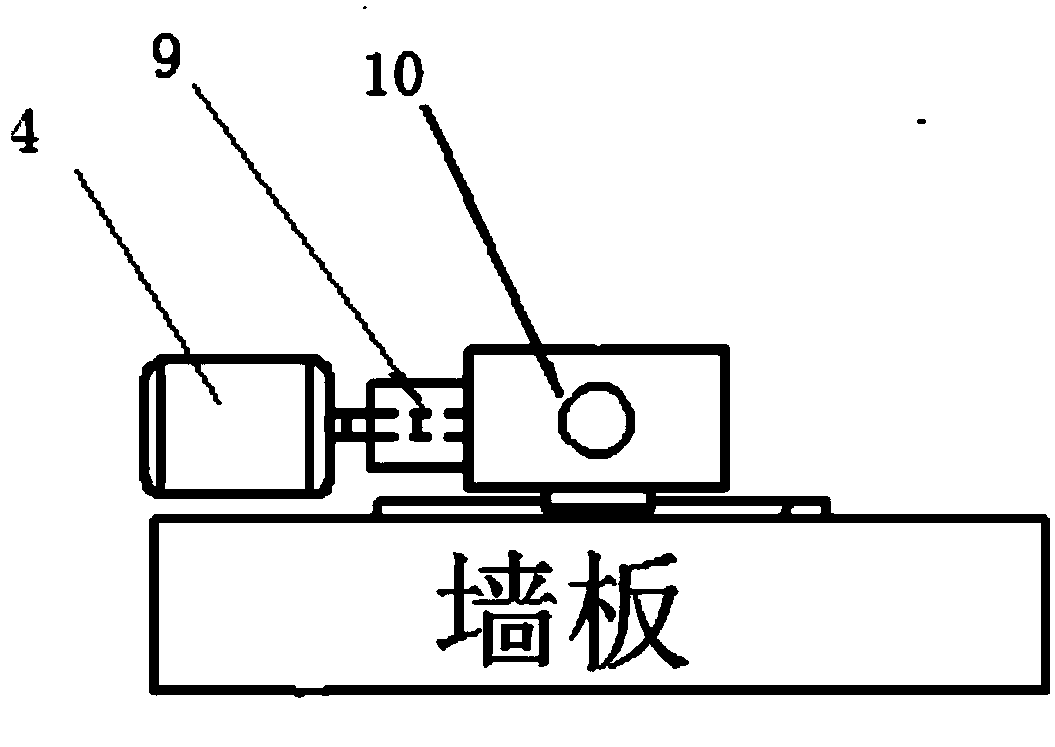

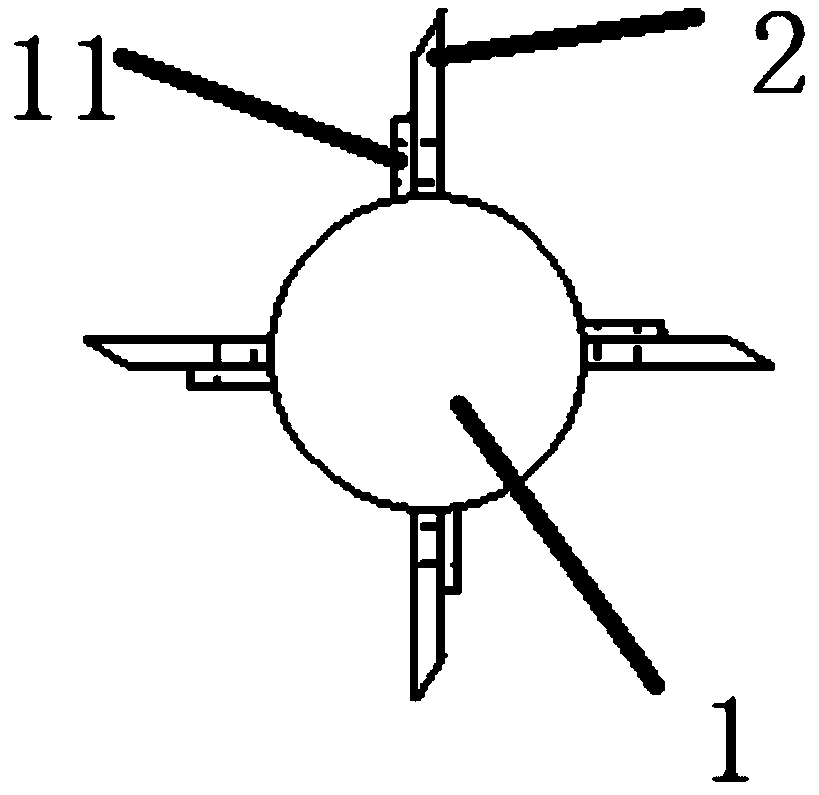

[0024] The invention provides a high-speed hot knife cutting device, such as figure 1 As shown, including the main shaft 1, a thermal blade 2 is arranged along the axis of the main shaft 1, and the thermal blade 2 is four blades perpendicular to each other, as image 3 Heating wires 11 are respectively arranged in the shown hot blade 2, self-aligning bearings 3 matched with the main shaft 1 are respectively arranged at both ends of the main shaft 1, and the surface of the self-aligning bearing 3 is also provided with a servo drive perpendicular to the outer surface of the main shaft 1. The motor 4 and the servo motor 4 are connected to the self-aligning bearing 3 through a ball screw 9, and one end of the main shaft 1 is also provided with a driving motor 5, and the main shaft of the driving motor 5 is connected to the main shaft 1 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com