Volute type sludge dehydrator

A sludge dewatering machine and stacking screw technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of low sewage discharge efficiency and easy blockage of water collection parts and other problems to achieve the effect of improving sewage discharge efficiency and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

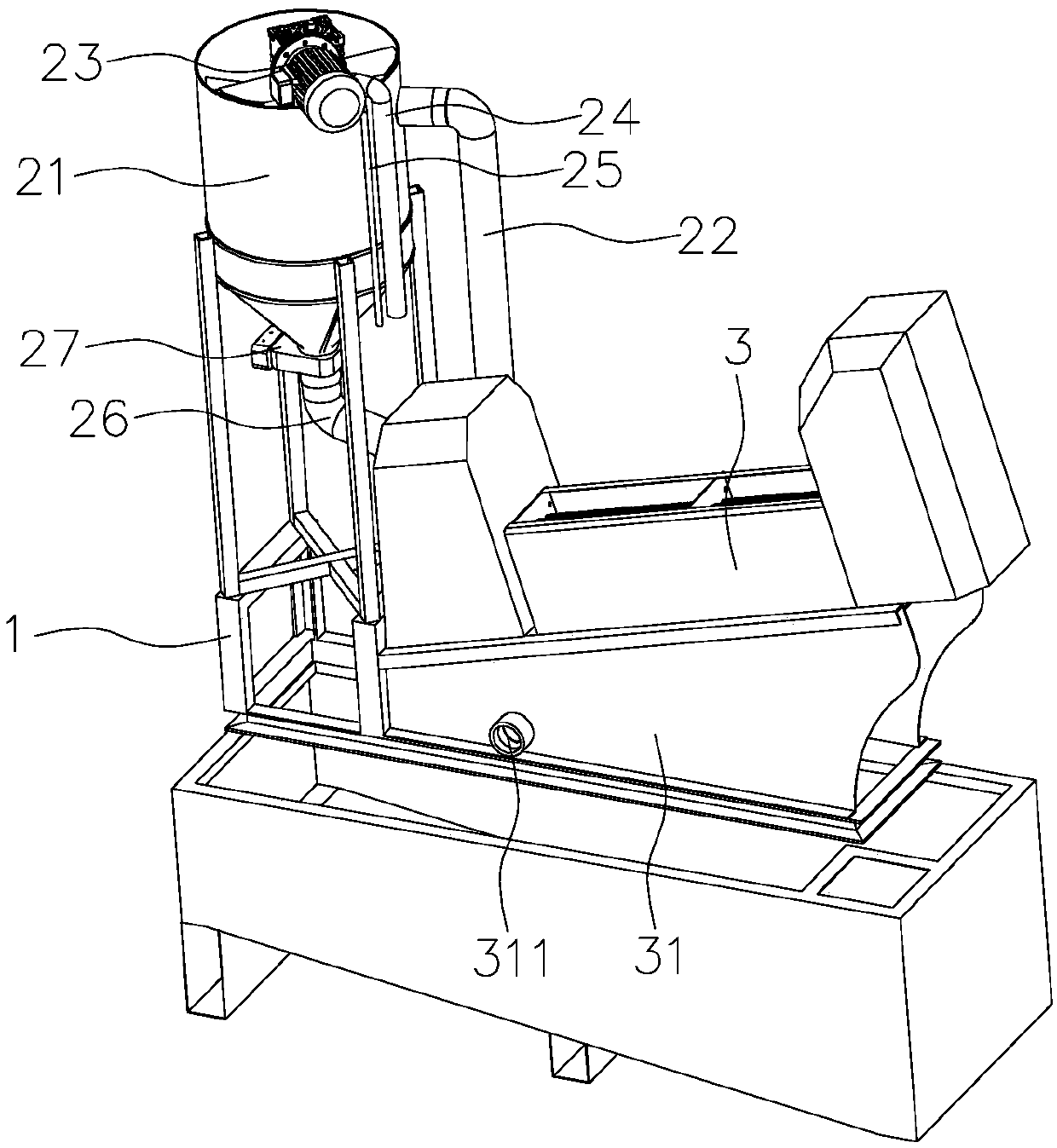

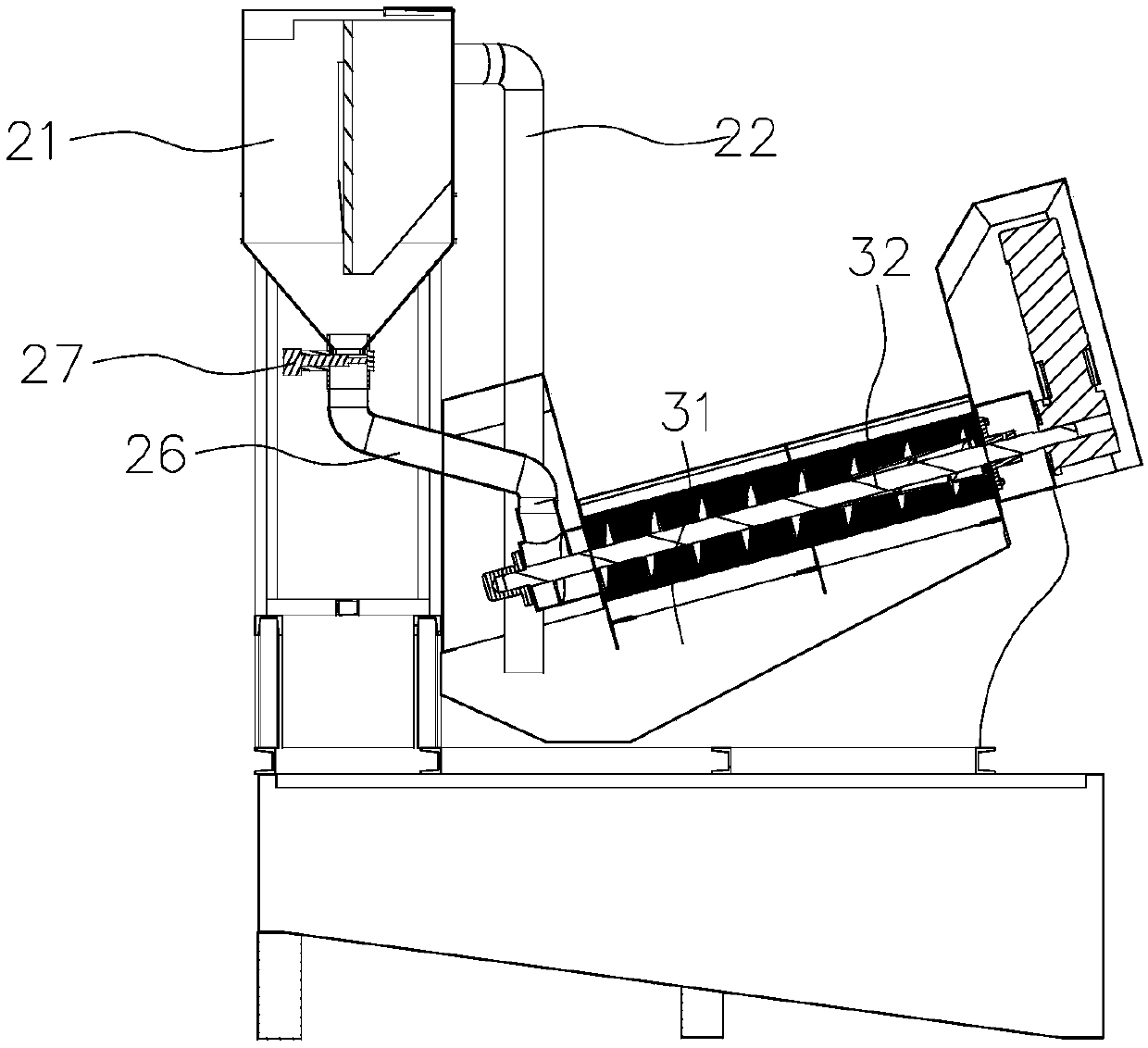

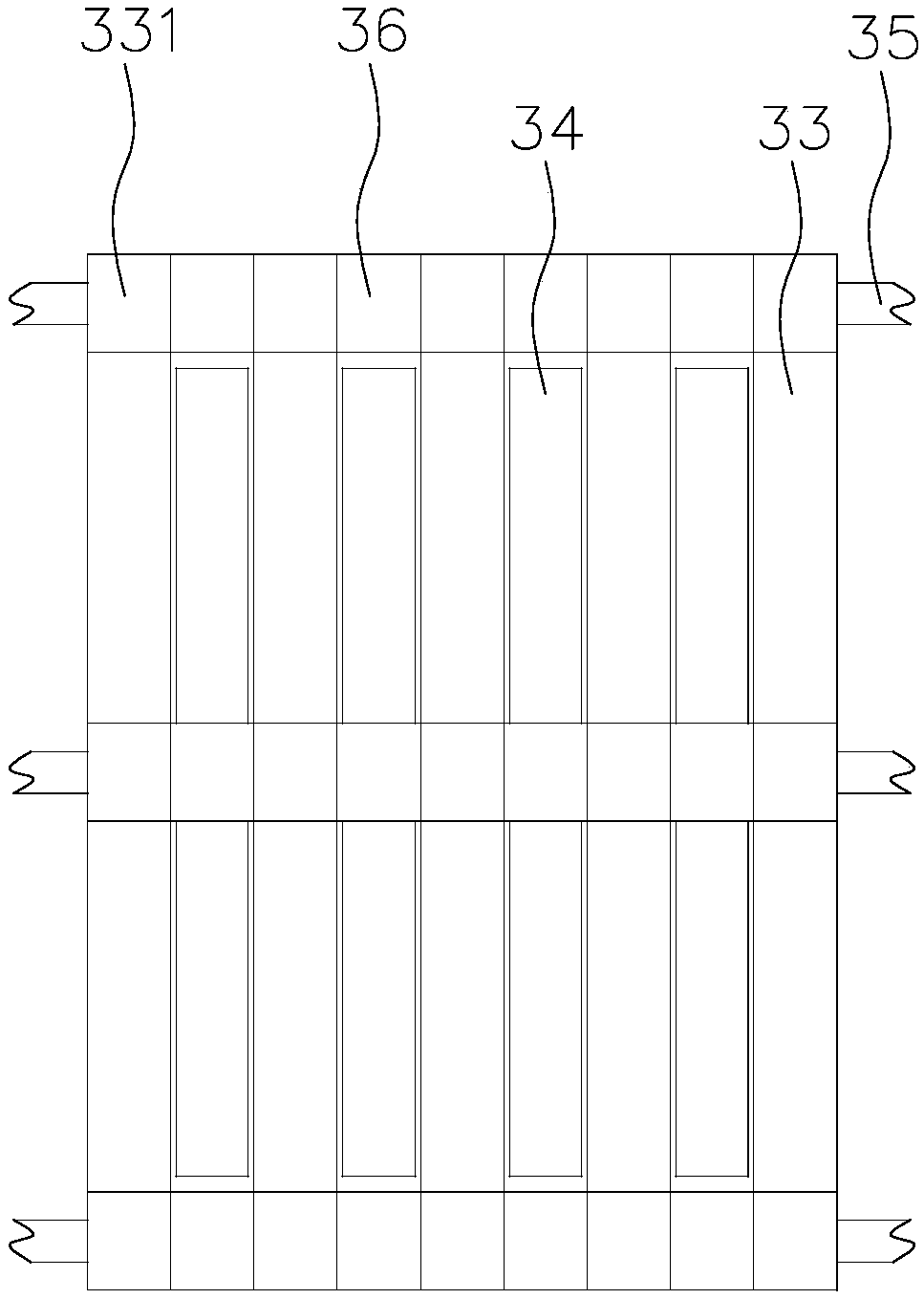

[0019] refer to Figure 1 to Figure 7 , this embodiment provides a stacking screw sludge dewatering machine, the structure of this device can refer to the structure of Chinese Patent No.: CN201510498260.0, which is an improvement based on this. It includes a frame 1, a stirring and flocculation device and a dehydration device 3 arranged on the frame 1, and the dehydration device 3 includes a water receiving tank 31 rotatably arranged on the frame 1, and a screw shaft 32 arranged on the frame 1 1. The stacked screw body located on the frame 1 outside the screw shaft 32, the water receiving tank 31 is provided with a drain port 311, and the stirring and flocculating device includes a water collecting tank 21, a water suction pipe connecting the water receiving tank 31 and the water collecting tank 21 22. The water pump 23 connected to the suction pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com