Process for processing glass bottle

A processing technology, glass bottle technology, applied in glass blowing, glass forming, glass reshaping, etc., can solve the problems of waste of raw materials, etc., and achieve the effect of increasing difficulty, increasing production difficulty, rapid positioning and clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

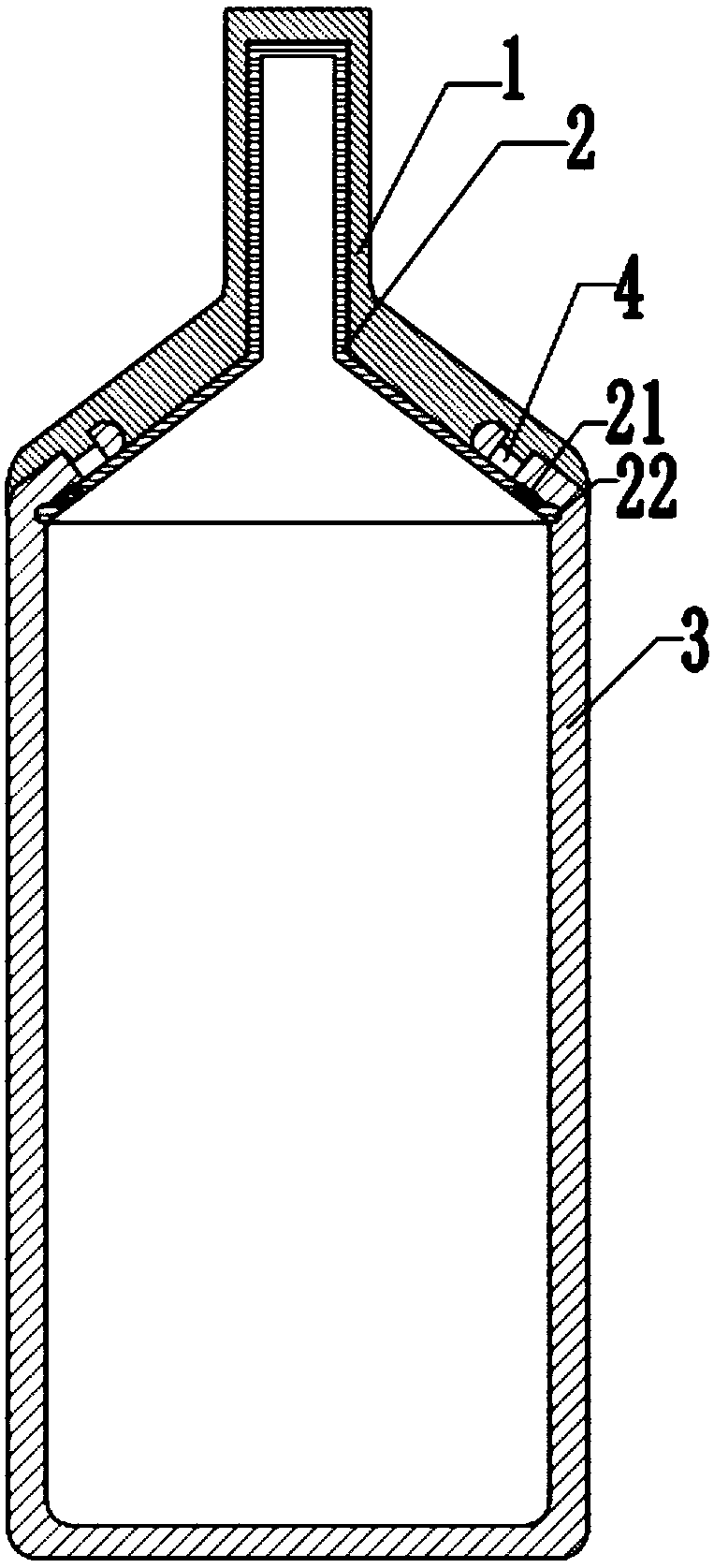

[0031] The embodiment is basically as attached figure 1 Shown: a glass bottle, including a bottle body 3 and a cover 2 connected to each other and a fixing layer 1 for fixing the bottle body 3 and the cover 2 . Both the lid 2 and the bottle body 3 are of glass structure.

[0032] Both the bottle body 3 and the cover 2 have a matching opening, and the opening of the bottle body 3 is located at its top, which is a shrinking neck whose diameter gradually decreases; The barrel part; the bottom barrel part is cylindrical with the same diameter. The diameter of the top of the shrinkage is more than two-thirds of the diameter of the bottom barrel. The diameter of the top of the constriction is large enough, so that it is more convenient to cover the lid 2 on the bottle body 3 . In addition, the bottom barrel part can also have a large diameter in the middle and small diameters at both ends, similar to the cavity structure of a big belly altar.

[0033] The opening of the lid 2 is...

Embodiment 2

[0047] The difference from Embodiment 1 is that before the lid 2 and the bottle body 3 are connected, the oxidation bag 4 has been put into the through hole. The oxidation package 4 in this embodiment includes connecting wires connected with the edible film material that can protrude outwards. Add oxidation bag 4 in the through hole of bottle body 3, each oxidation bag 4 all has the connection wire that stays outside the through hole to hang, avoids oxidation bag 4 to directly contact with the inboard mouth of through hole. After loading wine in the bottle body 3, when the lid 2 and the bottle body 3 are covered by the fixing ring and the limit groove, the connecting wire is released so that the oxidation bag 4 contacts the inner side of the through hole under gravity.

[0048] Finally, the molten rubber is poured on the outer surface of the joint between the lid 2 and the bottle body 3, and the entire rubber layer is pressed against the lid 2 and the bottle body 3 with a radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com