Method for reducing thermal cracking tendency of aluminum-based composite material by adding rare-earth Ce elements

A technology of aluminum-based composite materials and thermal cracking tendency, which is applied in the field of adding rare earth Ce elements to reduce the thermal cracking tendency of aluminum-based composite materials, can solve the problems of economic loss of material failure, reduction of material service life, and loss of people's property, etc., to achieve The effect of reducing the production cost, reducing the tendency of thermal cracking, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

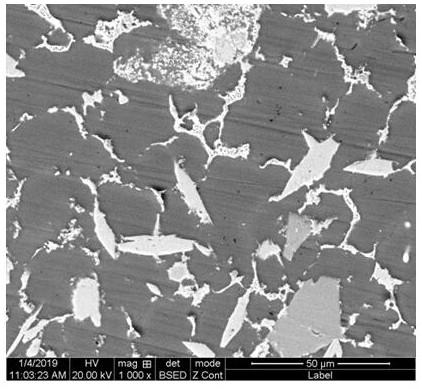

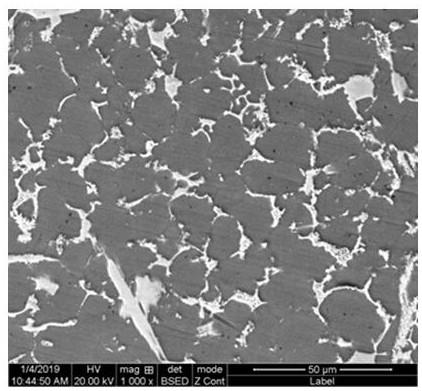

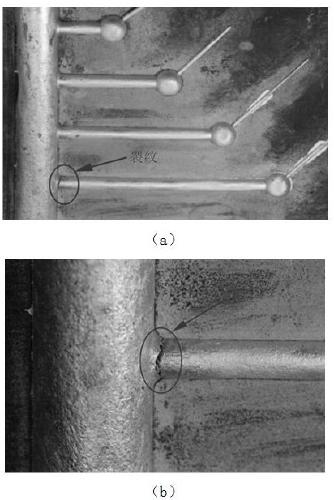

[0026] In this example, two composite material hot cracking tendency test experiments were carried out, namely, the hot cracking tendency test experiment without adding rare earth Ce element to the composite material and the hot cracking tendency test experiment adding 0.2% rare earth Ce element. Two experiments are compared to better illustrate the effectiveness of the inventive method. The following main content is the detailed process of the hot cracking tendency test experiment of adding 0.2% rare earth Ce element to the composite material:

[0027] Step 1. First weigh a certain mass of ZL205A alloy, and then calculate 5% of the mass of ZL205A alloy as TiB 2 the mass of the pellets;

[0028] Step 2, calculate and weigh the quality of Potassium Fluoborate and Potassium Fluotitanate according to the following total chemical reaction equation, and the total chemical equation is as follows:

[0029] 6KBF 4 +3K 2 TiF 6 +10Al=9KAlF 4 +K 3 AlF 6 +3TiB 2

[0030] Relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com