Method for improving thermal cracking tendency of ZL205A alloy based on nano Y2O3 particles

A ZL205A, hot cracking tendency technology, applied in the field of improving the hot cracking tendency of ZL205A alloy based on nanoparticles, can solve the problems of large addition amount, high temperature requirements, complicated operation, etc., and achieves reduced hot cracking tendency and fine grain size. The effect of homogenization and tissue homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

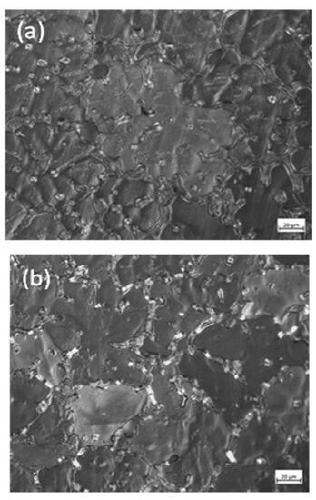

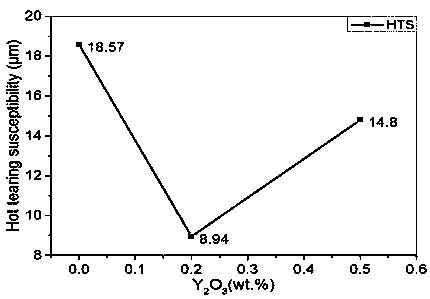

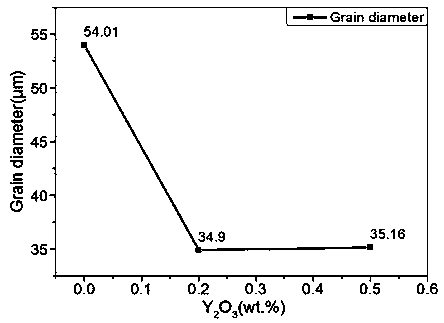

[0022] According to the ratio, the nano Y content will account for 0.2% of the total mass of ZL205A alloy 2 O 3 After the pellets are placed in a drying oven at 250°C for two hours, they are wrapped in aluminum foil with a size of 0.1*20*30mm into multiple small aluminum foil packages, and added to the molten 2.5Kg ZL205A alloy in multiple additions. After stirring evenly, put the crucible containing the semi-solid alloy in a resistance furnace at 750℃ to heat and stir. After the adding process is completed, stir evenly and keep it for 30 minutes, remove the residual slag on the surface, and then add The alloy melt of the pellets is kept for 30 minutes and stirred, and then poured into a CRC mold that has been preheated at a constant temperature of 250°C for two hours in the drying box at a temperature of 730°C to obtain an alloy that can improve the hot cracking tendency of ZL205A alloy Alloy material, the grain structure of the alloy material is uniform and refined compared to...

Embodiment 2

[0024] According to the ratio, the nano Y content will account for 0.5% of the total mass of ZL205A alloy 2 O 3 The pellets are placed in a drying box and kept at 250℃ for two hours, wrapped in aluminum foil with a size of 0.1*20*30mm into multiple small aluminum foil packages, and added to the molten 2.5Kg ZL205A alloy melt in multiple additions. After stirring evenly, put the crucible containing the semi-solid alloy in a resistance furnace at 750℃ to heat and stir. After the addition process is completed, stir evenly and keep it for 30 minutes, remove the residual slag on the surface, and then add the particles After the alloy melt is kept for 30 minutes and stirred, it is poured into the CRC mold which has been preheated at a constant temperature of 250°C for two hours in the drying box at a temperature of 730°C to obtain an alloy material that can improve the hot cracking tendency of ZL205A alloy. The grain structure is uniform and refined compared to the base ZL205A alloy; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com