Preparation method of aluminum based composite material with low hot-crack tendency

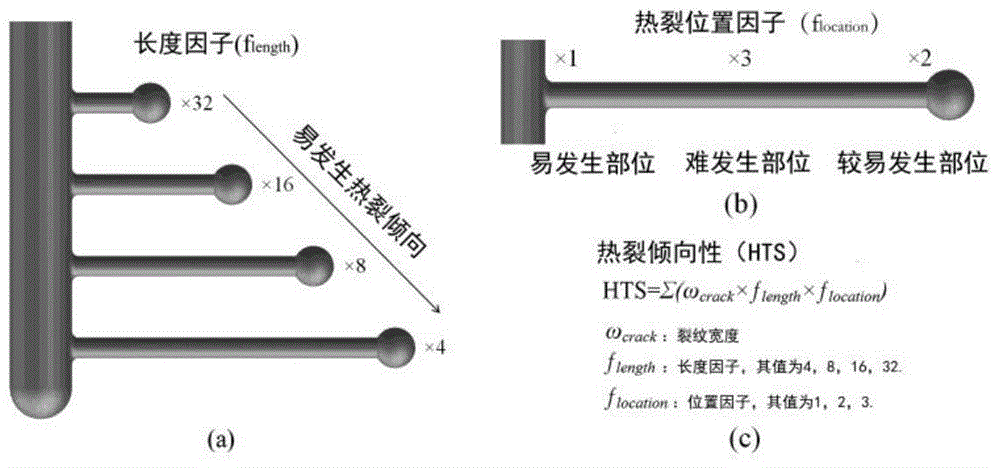

An aluminum-based composite material and a tendency technology, applied in the field of composite materials, can solve the problems of high cost of rare earth metals, reduce the tendency of hot cracking, etc., and achieve the effect of narrowing the crystallization temperature range, reducing the tendency of hot cracking, and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Put 5Kg of ZL205A alloy into a crucible and melt it. When the temperature reaches 800°C, according to TiB 2 Add K to the content of 0.2wt% of ZL205A alloy 2 TiF 6 and KBF 4 Mix salt and stir for 10 minutes. After the reaction is over, pour out the reaction product. After refining, pour it into the ingot mold at 720°C to obtain TiB with low thermal cracking tendency. 2 / ZL205A composite material, thermal cracking tendency is 15.

Embodiment 2

[0021] Put 5Kg of ZL205A alloy into a crucible and melt it. When the temperature reaches 950°C, according to TiB 2 Add K to the content of 1.5wt% of ZL205A alloy 2 TiF 6 and KBF 4 Mix salt and stir for 30 minutes. After the reaction is over, pour out the reaction product. After refining, pour it into the ingot mold at 750°C to obtain TiB with low thermal cracking tendency. 2 / ZL205A composite material, thermal cracking tendency is 12.

Embodiment 3

[0023] Put 5Kg of ZL205A alloy into a crucible and melt it. When the temperature reaches 875°C, according to TiB 2 Add K to the content of 0.8wt% of ZL205A alloy 2 TiF 6 and KBF 4 Mix salt and stir for 20 minutes. After the reaction is over, pour out the reaction product. After refining, pour it into the ingot mold at 735°C to obtain TiB with low thermal cracking tendency. 2 / ZL205A composite material, thermal cracking tendency is 13.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com