A method of solidifying under pressure to prepare al-cu alloy with high cu content

An al-cu and alloy technology, which is applied in the field of preparation of Al-Cu alloy with high Cu content, to achieve the effects of improving microstructure uniformity and mechanical properties, expanding the application range, and reducing the tendency of hot cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following part is a specific implementation to further explain the present invention, but the following implementation is only a further explanation of the present invention, and does not mean that the protection scope of the present invention is limited to this, and all equivalent replacements based on the ideas of the present invention are included in this document. protection scope of the invention.

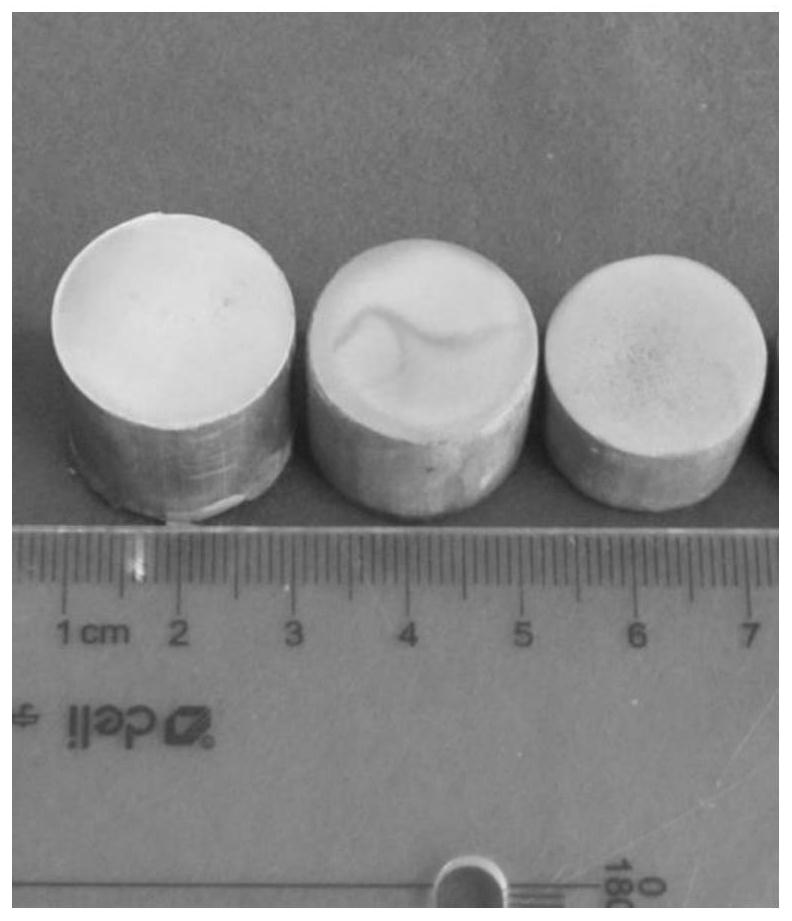

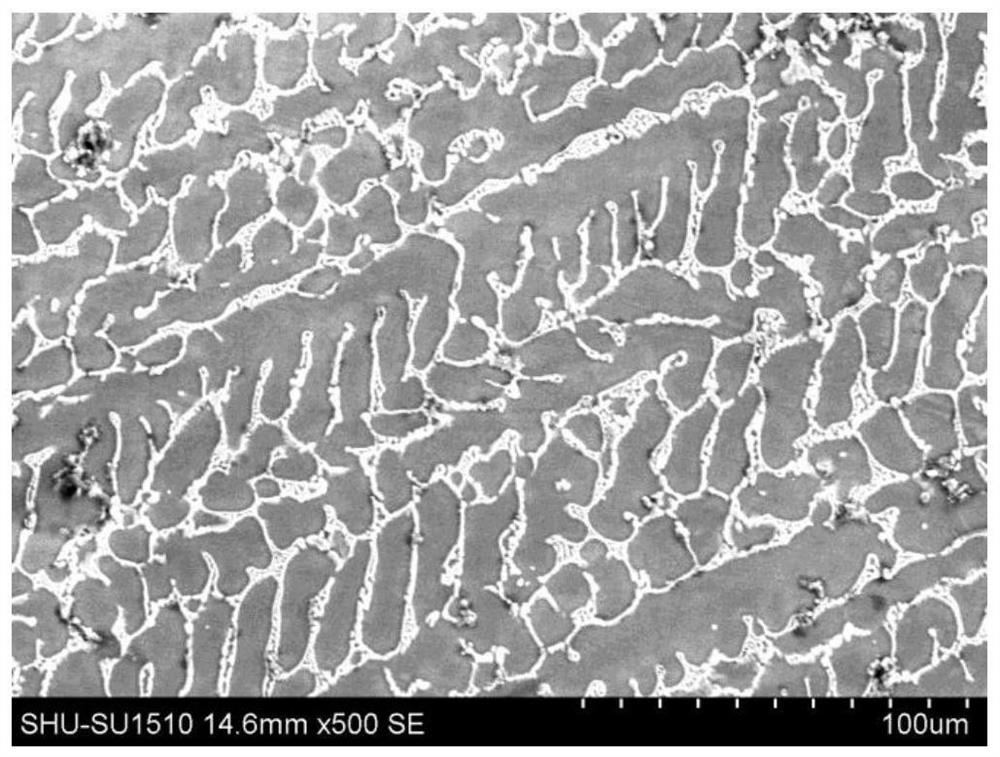

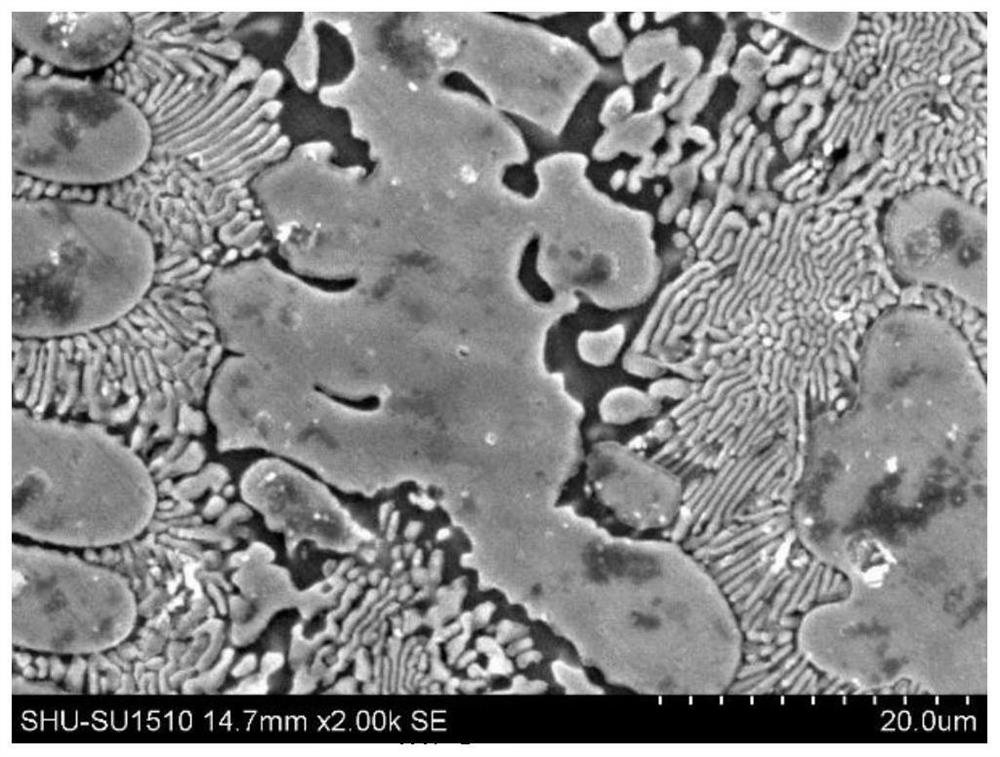

[0035] Take the Al-Cu alloy of high copper content as an example to further describe the present invention:

[0036] 1. The preparation process of Al-Cu master alloy with high Cu content, step A mainly includes the following steps:

[0037] The raw materials of A1 fusion alloy are high-purity aluminum (99.9% Al) and high-purity copper (99.9% Cu). Put the weighed metal material into the quartz crucible according to the mass ratio and adopt induction melting.

[0038] The A2 alloy is melted in an intermediate frequency vacuum induction furnace. The melting temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com