A wall thermal insulation module connecting piece and a thermal insulation integrated structure

A technology for thermal insulation modules and connectors, applied in thermal insulation, walls, building components, etc., can solve problems such as easy falling off of protective layers, and achieve the effects of reducing material costs, shortening construction periods, and reducing production and construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

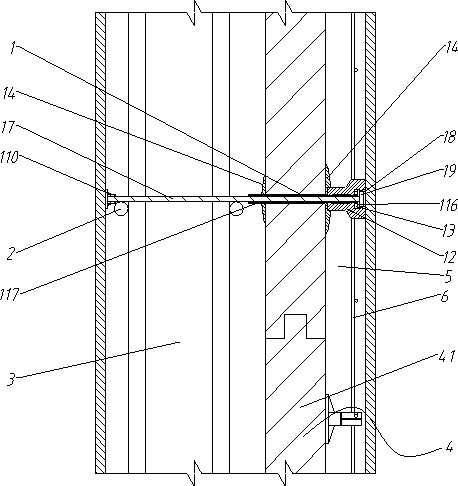

[0052] Embodiment 1: as Figure 1~10 As shown, a wall insulation module connector, including:

[0053] Connecting sleeve 11, connecting sleeve 11 is provided with reinforcing holes 16 along the circumference;

[0054] A positioning plate 12, the positioning plate 12 is arranged on one end of the connecting sleeve 11, and the positioning plate 12 is provided with a gap 13 for fixing the steel wire mesh;

[0055] The connection plate 14, the middle part of the connection plate 14 is provided with a through hole 15 for the connection sleeve 11 to pass through, the connection plate 14 is set on the outside of the connection sleeve 11, and there are two connection plates 14;

[0056] Reinforcing ribs 17 are provided in the reinforcing holes 16 .

[0057] In this embodiment, the positioning plate 12 and the connecting sleeve 11 are integrally formed, the steel wire mesh of the protective layer is fixed on the gap 13 of the positioning plate 12, the insulation layer is clamped by t...

Embodiment 2

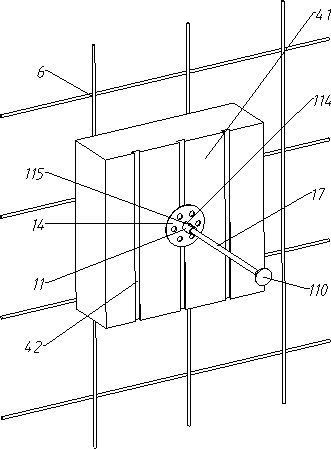

[0067] Such as figure 1 , 2 , 5, 8, and 9,

[0068] Further, the notch 13 is located on the side of the positioning plate 12 away from the connecting plate 14, and is located on the side of the positioning plate 12 close to the reinforcing rib 17. The positioning plate 12 is also provided with a buckle 121, and the buckle 121 is located at the notch 13 and is away from the connecting plate 14. The side also includes a card 116, the card 116 is circular, and the edges of the card 116 are snapped into several buckles 121.

[0069] In this embodiment, the wire mesh 6 can be snapped into the gap 13, and the wire mesh 6 can be fixed in the gap 13 by snapping the card 116 into the buckle 121. The installation is simple and quick, and the wire mesh 6 can be locked. Make steel wire mesh 6 not easy to come off.

[0070] Further, a circular hole is provided in the middle of the card 116 through which the reinforcing rib 17 passes.

[0071] In this embodiment, the reinforcing rib 17 ...

Embodiment 3

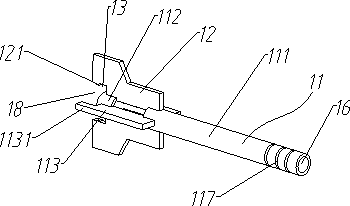

[0077] Such as image 3 , 4 , 6, 8, and 9,

[0078] Further, the notch 13 includes a snap-in portion 131 whose width gradually decreases from the end to the inside, and the notch 13 also includes a snap-in portion 132 that communicates with the narrowest end of the snap-in portion 131 .

[0079] In this embodiment, the width of the connection between the engaging part 131 and the clamping part 132 is smaller than the diameter of the steel wire of the steel mesh. Since the positioning plate 12 and the connecting sleeve 11 are integrally formed of plastic, they have certain elasticity, so the steel wire of the steel mesh can be added part and snapped into the clamping part 132, the construction is convenient and no additional fixing parts are needed, the construction efficiency is improved, and the construction and installation cost is reduced.

[0080] Further, the side of the other end of the connecting sleeve 11 provided with the positioning plate 12 is provided with a prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com