High-performance autoclaved aerated concrete integrated board exterior wall structure for prefabricated building

An autoclaved, high-performance technology, used in building structures, building components, buildings, etc., can solve problems such as cracking and leakage of external walls, and achieve the effects of ensuring thermal insulation and fire performance, excellent thermal insulation and fire performance, and stable connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A further description will be given below in conjunction with specific embodiments.

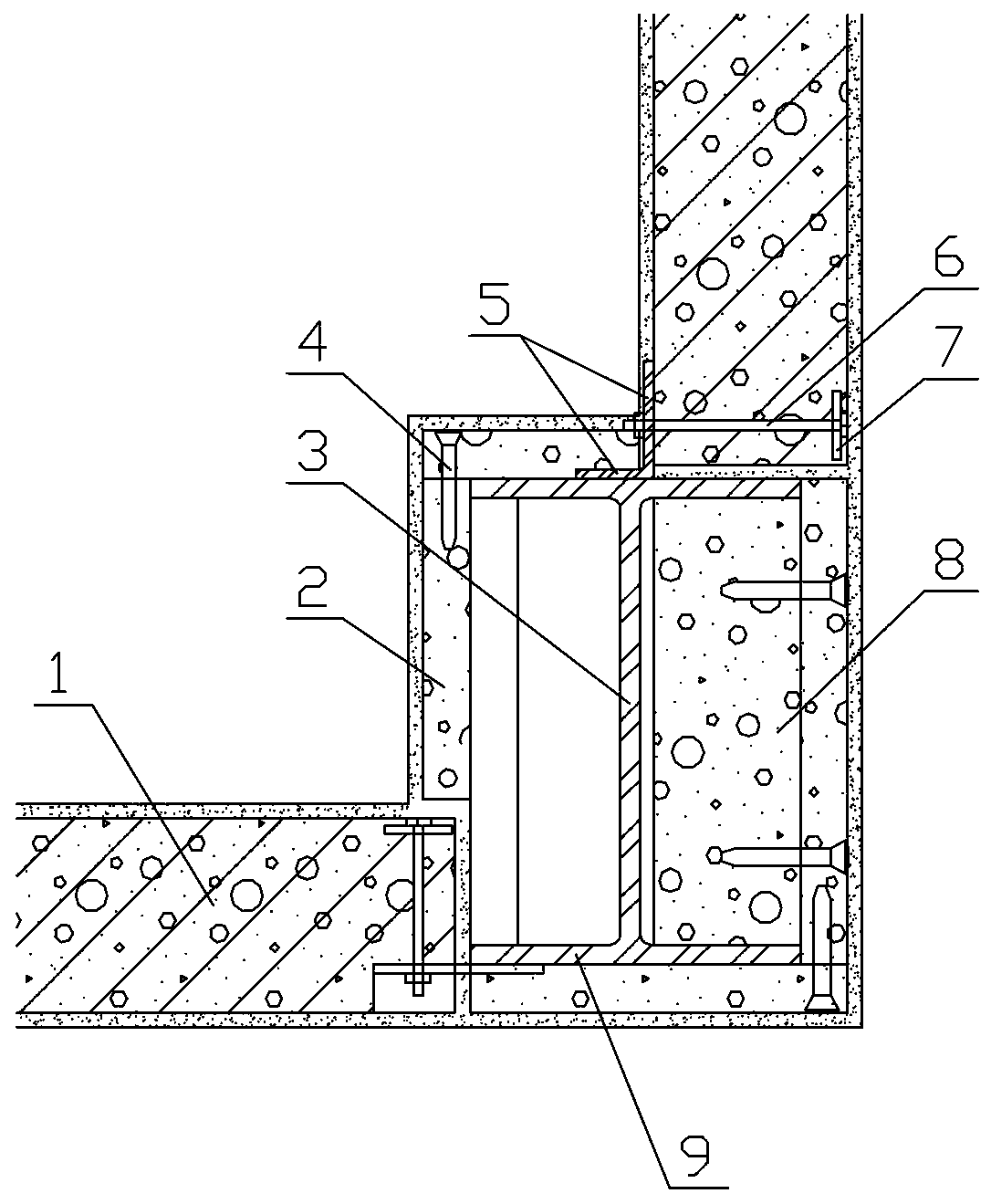

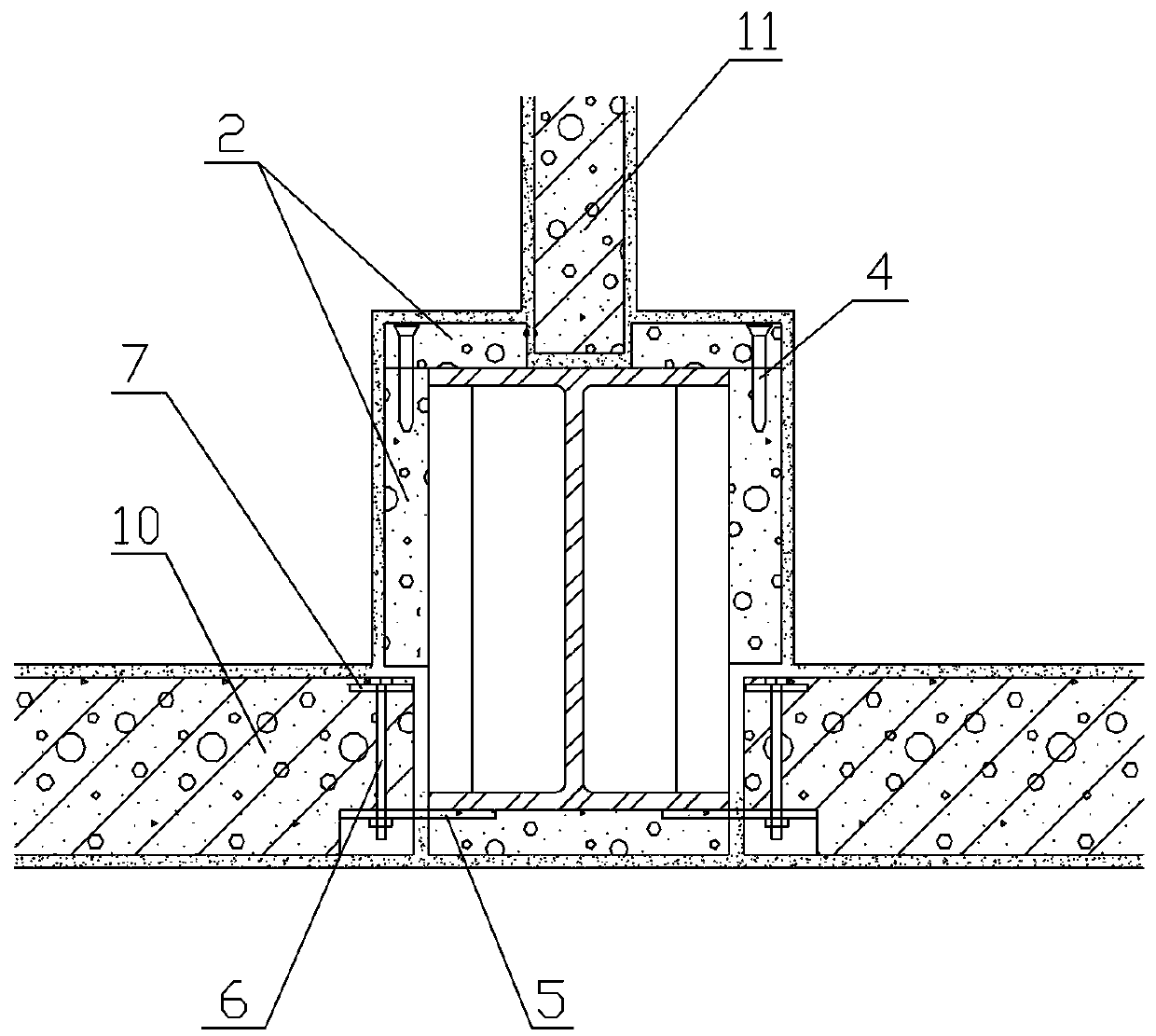

[0018] See figure 1 It is the first implementation mode, a high-performance autoclaved aerated concrete integrated panel exterior wall structure for prefabricated buildings, including a high-performance autoclaved aerated concrete integrated panel body 1 and I-shaped structural steel columns or I-shaped Structural steel beams, the main reinforcements inside the ends of the high-performance autoclaved aerated concrete integrated board body are pre-embedded and welded with iron parts 7 with bolt holes, and the ends of the high-performance autoclaved aerated concrete integrated board body The steel connector 5 (steel plate or angle steel), the iron part and the wing plate 9 or web 3 in the I-shaped structural steel column or I-shaped structural steel beam are connected by bolts 6 and then welded to form a whole assembly building The external wall panels; the exposed part of the I-shaped stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com