Segment splicing vehicle and splicing method

A segment assembling and segmenting technology, which is applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of unstable construction quality, low construction efficiency, and high labor intensity, and achieve complete machine transfer operations and reduce The effect of labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical features and technical effects of the technical solution of the present invention more clear, the exemplary solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of specific embodiments of the present invention.

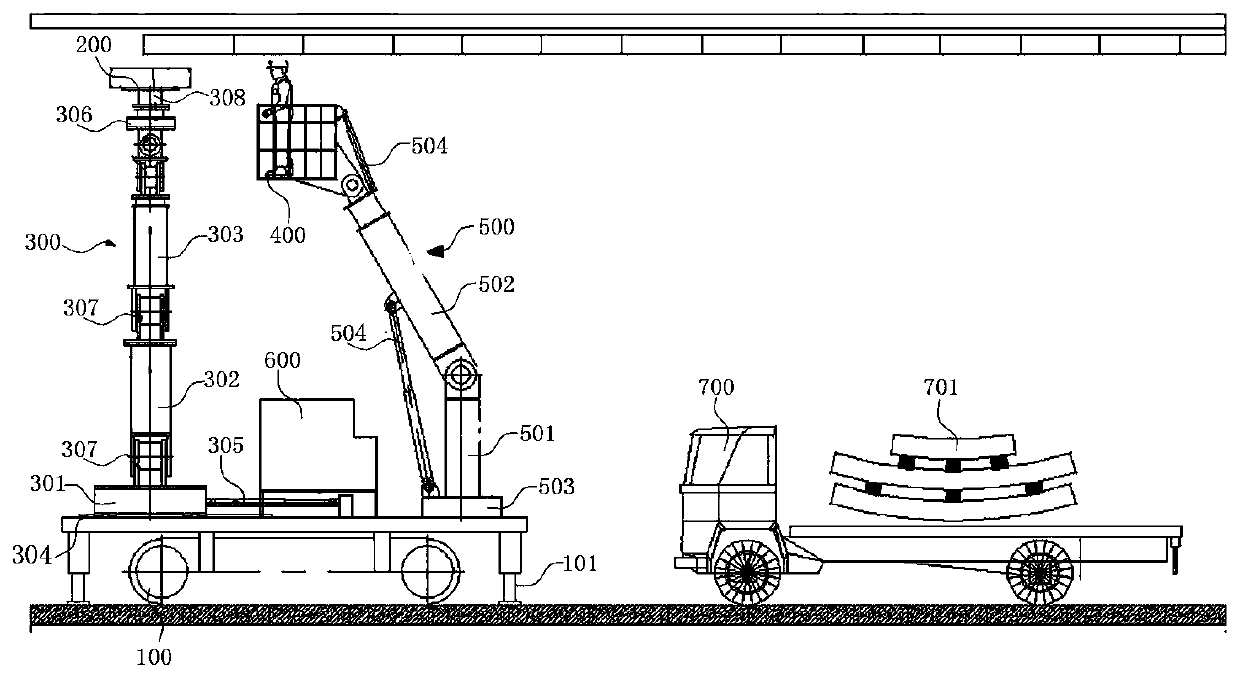

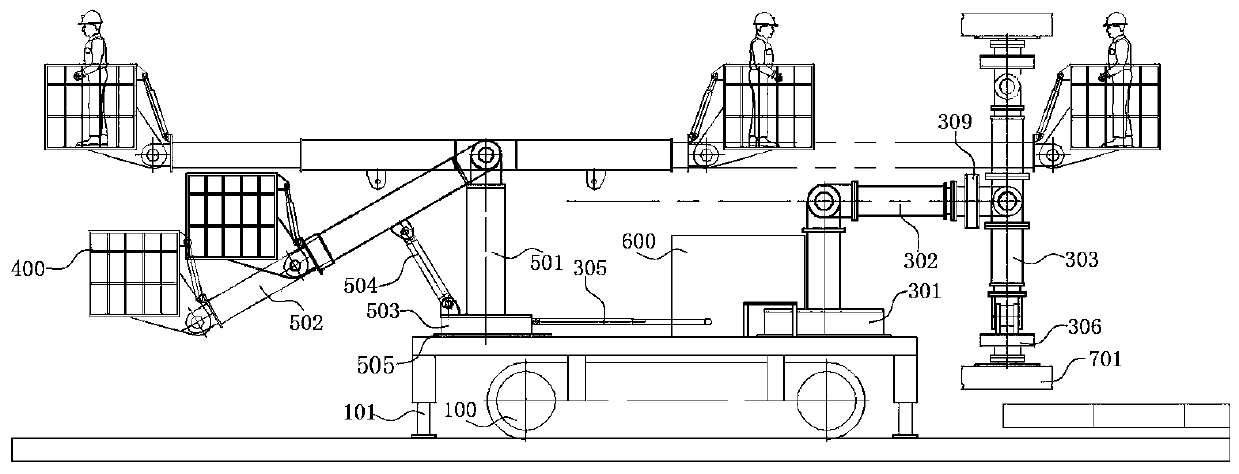

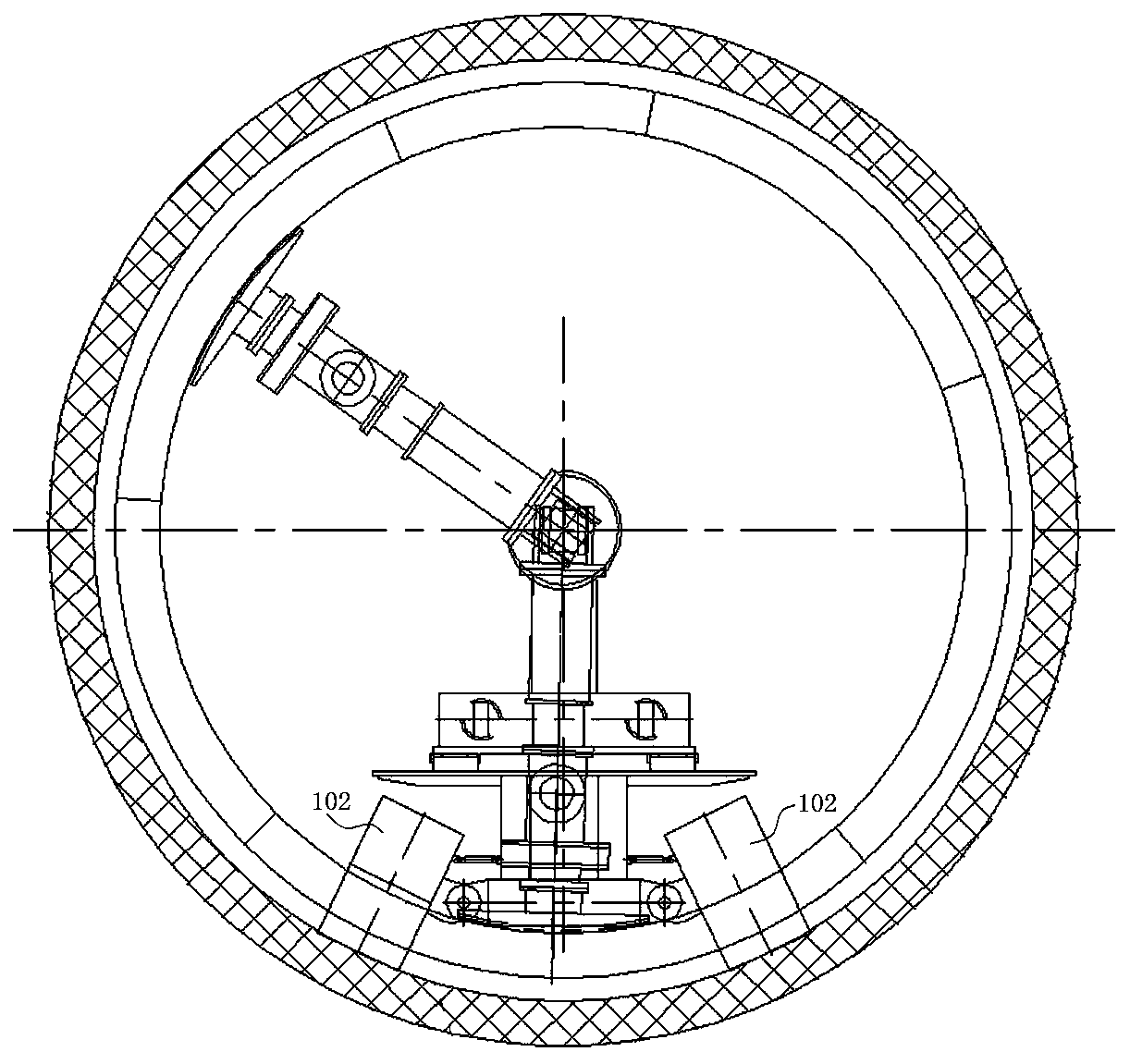

[0040] see Figure 1-Figure 5 , the application discloses a segment assembly vehicle, including a traveling vehicle, a segment grabbing assembly 200, an assembly arm assembly 300, a service platform 400, a support arm assembly 500, and a control system 600. The traveling vehicle in this embodiment is a crawler Car 100, the bottom of the tracked vehicle is provided with telescopic outriggers 101 and support cylinders 102, and the support cylinders 102 are arranged on both sides of the crawler vehicle 100 in a figure-eight shape. Traveling in the bottom tunnel, the telescopic outrigger 101 provided by the crawler vehicle 100 is retracted during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com