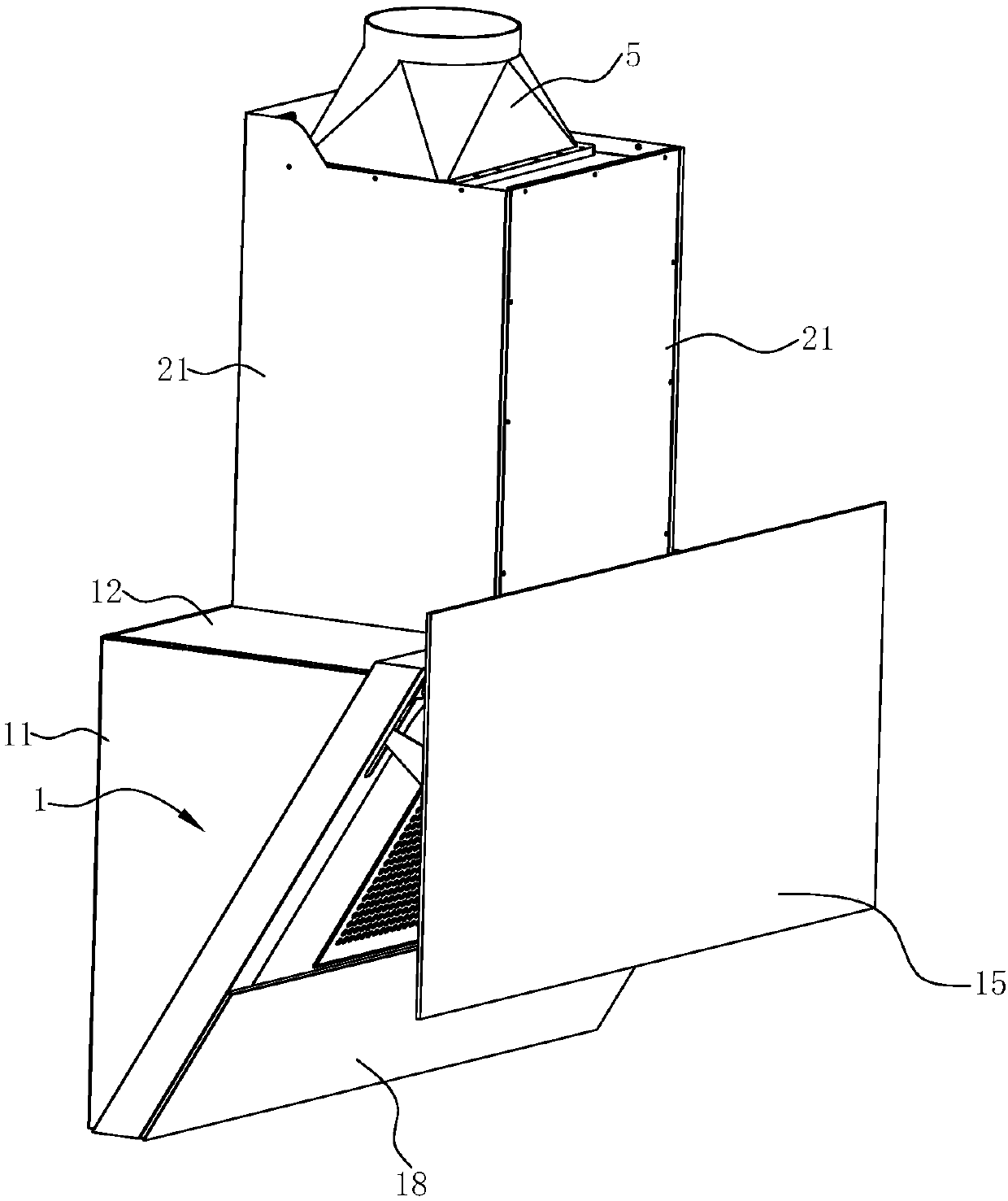

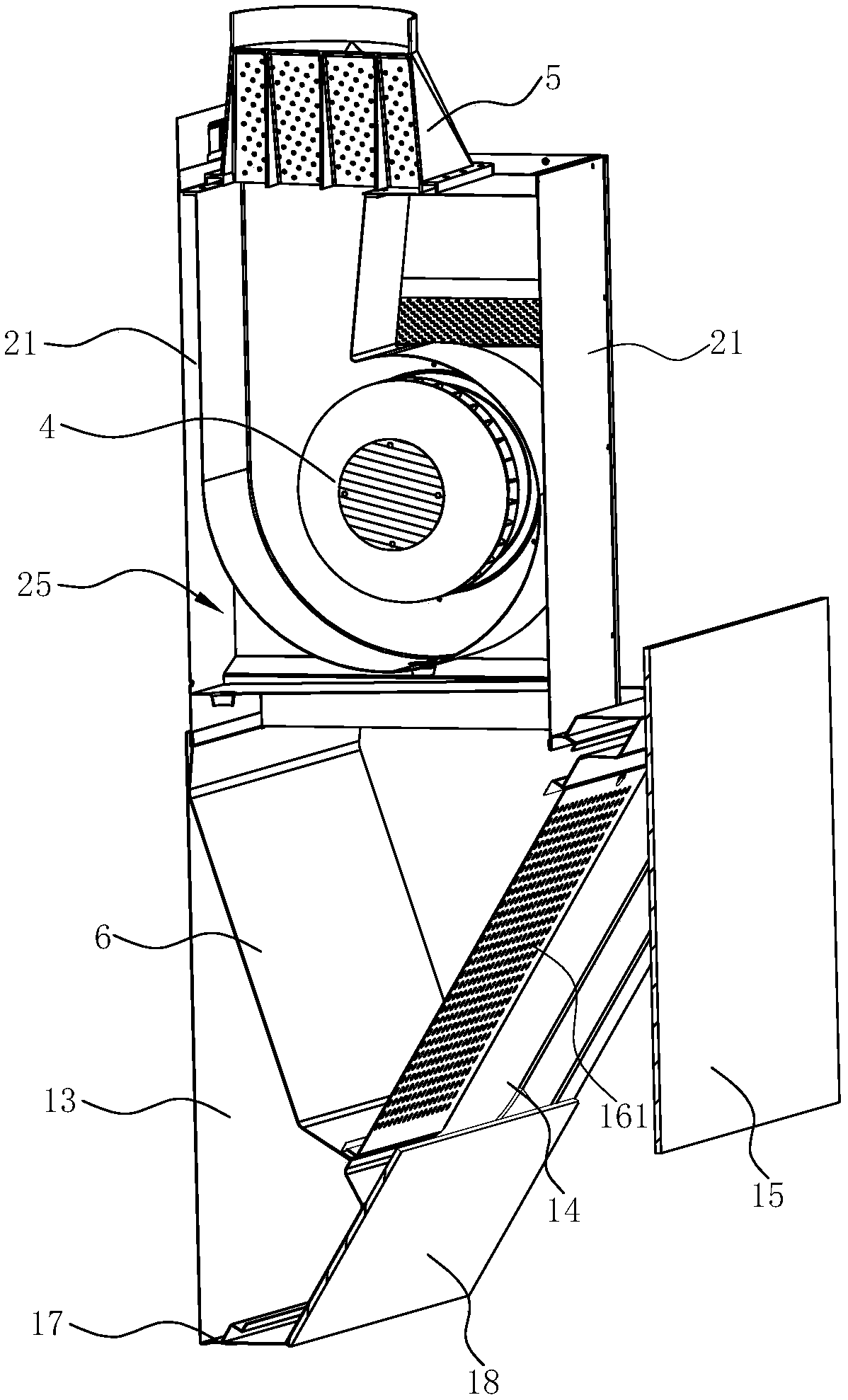

Near suction type extractor hood

A range hood and near-suction technology, applied in the field of kitchen appliances, can solve the problems of unfavorable impeller performance, difficulty in overcoming duct resistance, long distance of air outlet ducts, etc. The effect of improving smoking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

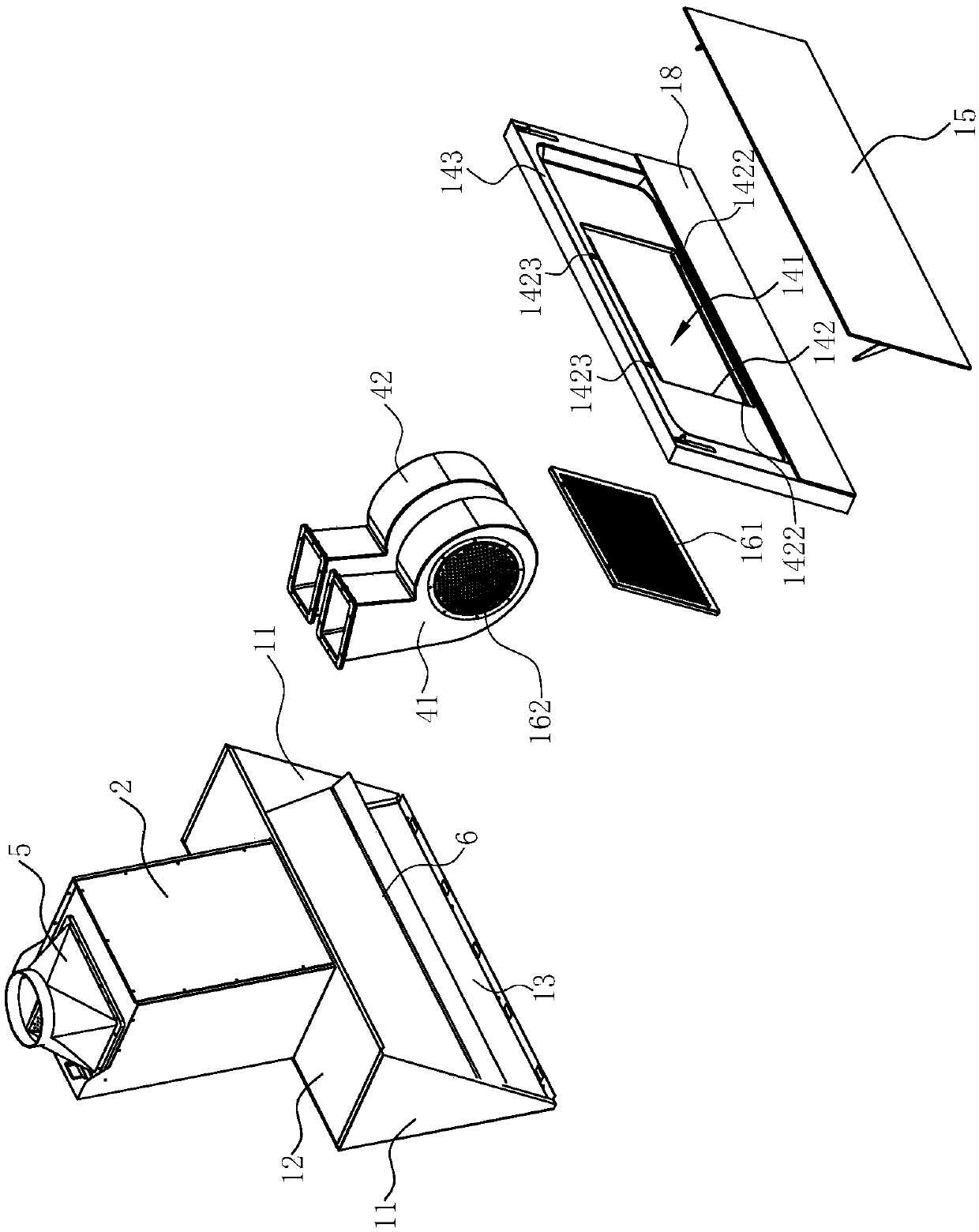

Embodiment 2

[0051] see Figure 8 and Figure 9 , in this embodiment, the difference from the first embodiment above is that the first ternary fan system 41 and the second ternary fan system 42 share the same volute 44, that is, the first ternary fan system 41 of the first ternary fan system 41 The first three-way impeller 412 and the second three-way impeller 422 of the second three-way blower system 42 are both arranged in the same volute 44 .

[0052] A mounting plate 45 is arranged between the two ternary impellers, thereby separating the two ternary impellers on both sides of the mounting plate 45, and the mounting plate 45 extends to the top of the volute 44, thereby dividing the volute 44 into two The first oil fume passage 441 and the second oil fume passage 442 are independent. The driving motor 43 passes through the mounting plate 45 and is connected and fixed with the mounting plate 45 .

[0053] In this embodiment, the air outlet cover 5 only includes a cover body 51 and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com