Device for sampling through continuous wiping, and sample feeding system for conveying gas

A sampling device and sample technology, which is applied to sampling devices, analytical materials, instruments, etc., can solve the problem that the wiper sampler cannot continuously take samples, and achieve the effect of high wipe sampling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

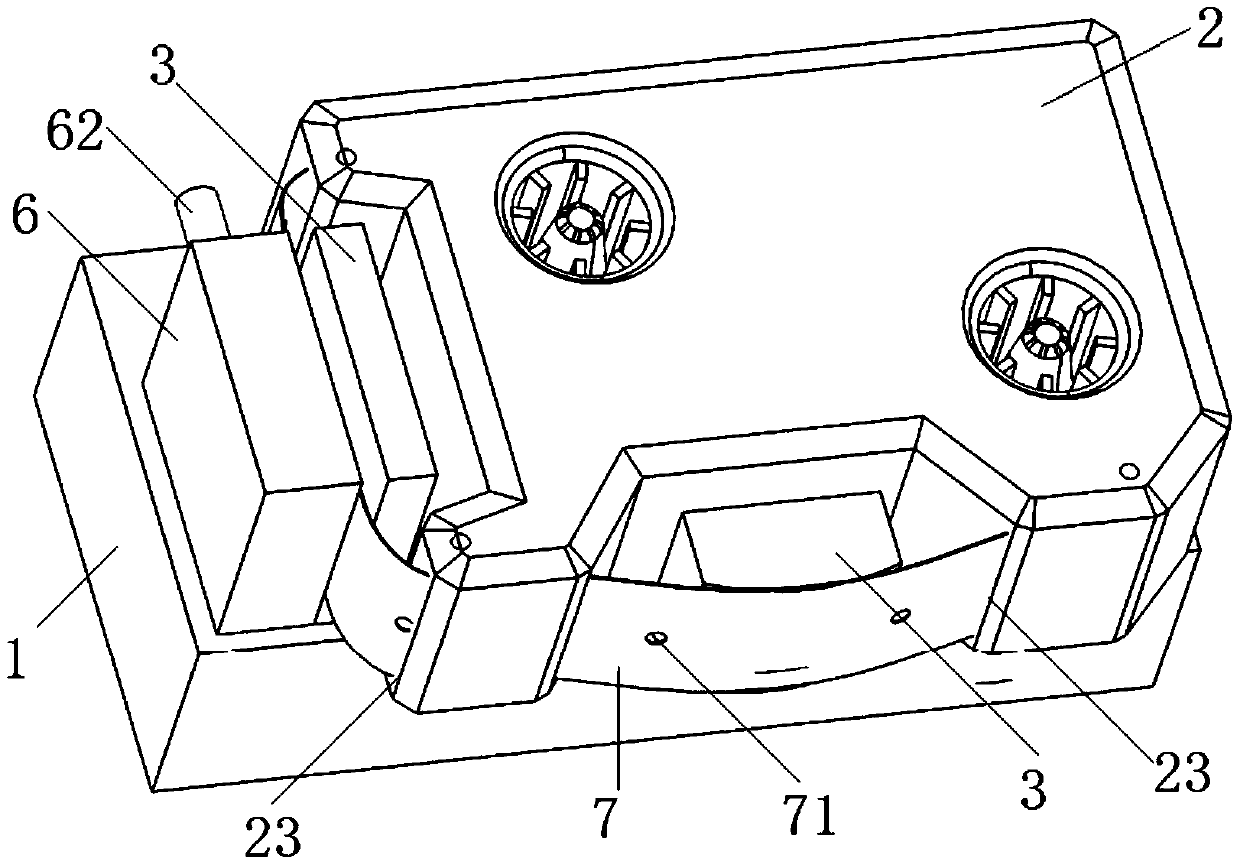

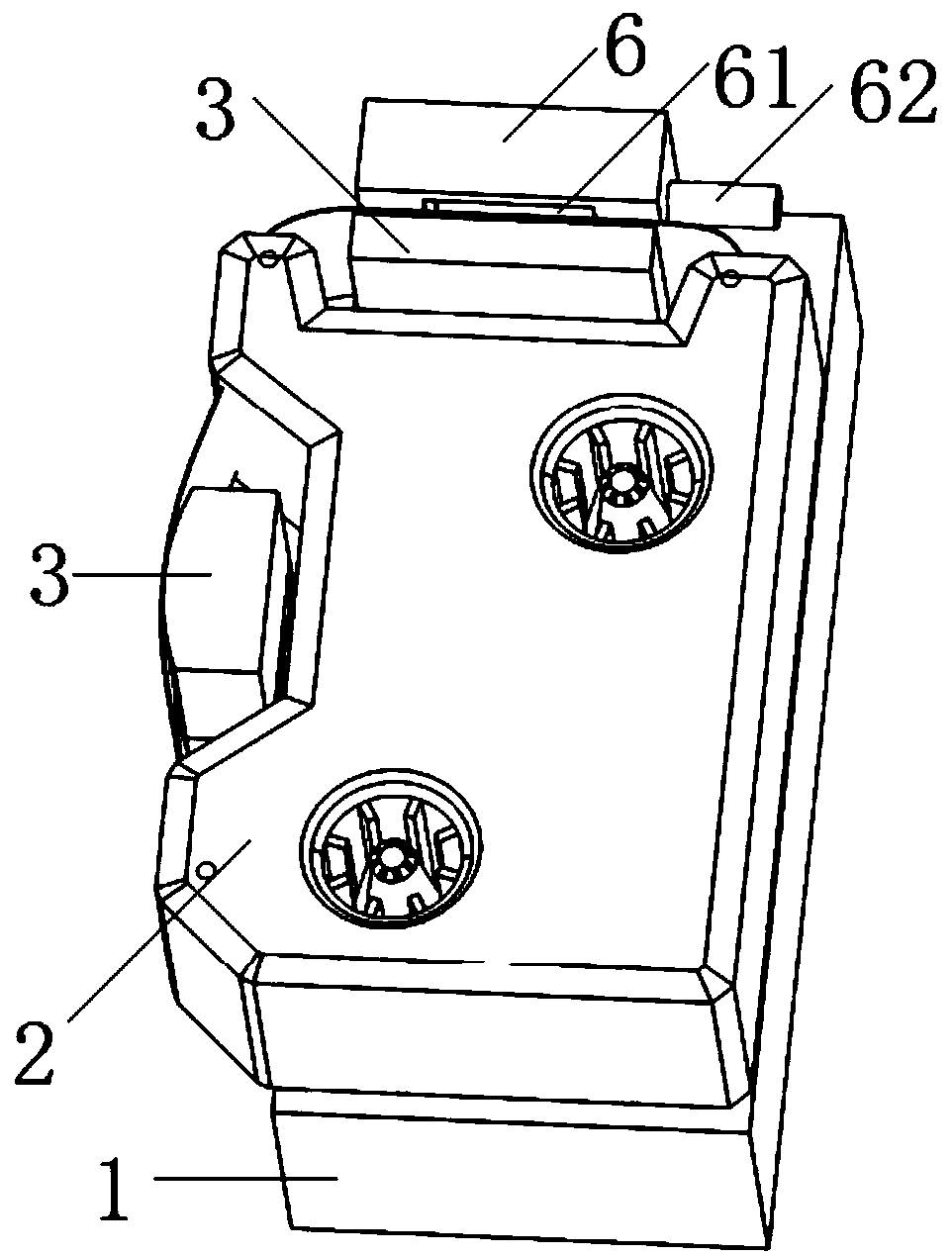

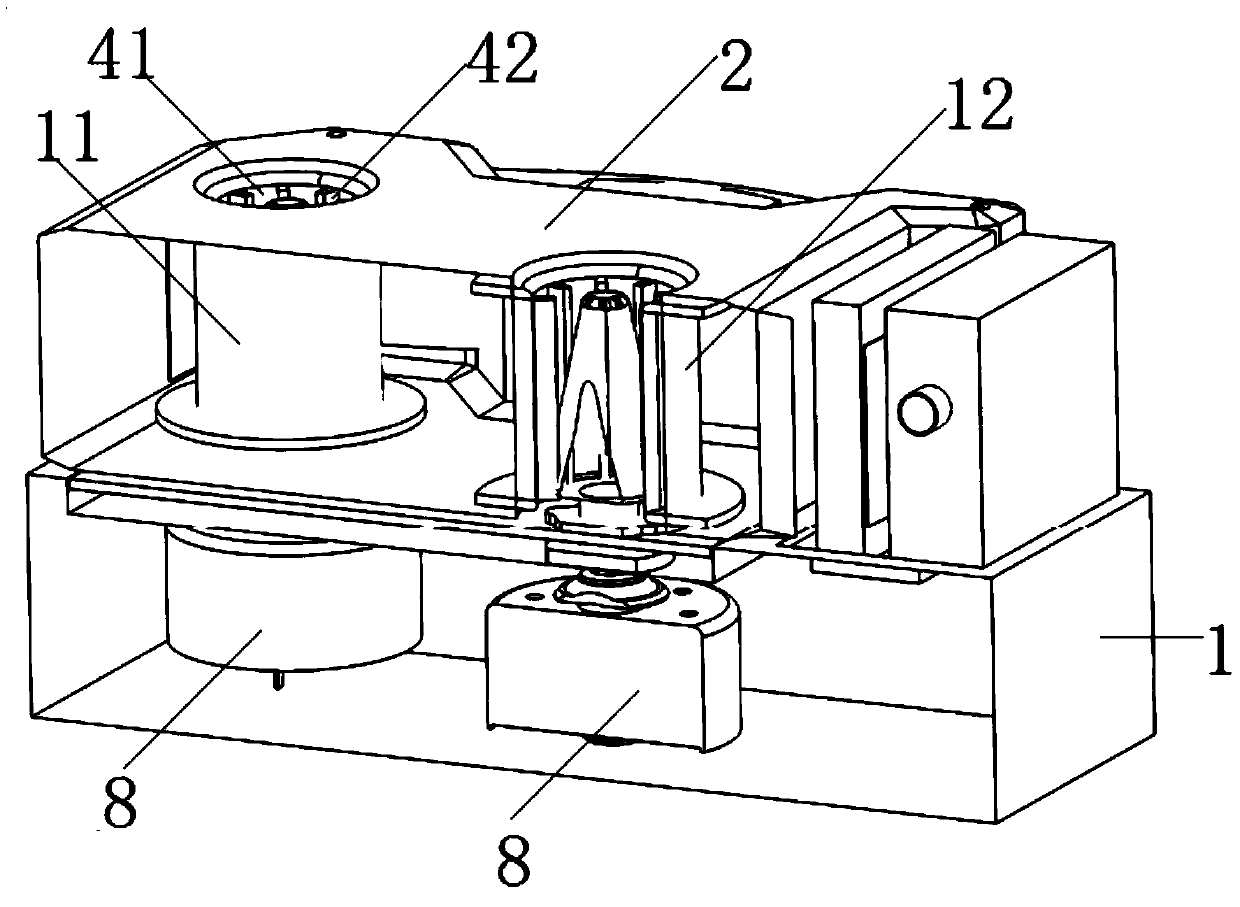

[0056] This embodiment provides a continuous wiping sampling device, such as Figure 1 to Figure 3 As shown, it includes a base 1, a first roller 11 and a second roller 12, and a test paper roll.

[0057] Wherein, the base 1 is provided with a sampling interval and an unloading interval, such as image 3 As shown, the first roller 11 and the second roller 12 are spaced and rotatably arranged on the base 1, the test paper is wound on the first roller 11, and the withdrawn end of the test paper roll drawn from the first roller 11 is wound on the second roller. On the roller 12, the test paper roll drives the extraction end to pass through the sampling interval and the sample unloading interval successively under the rotation of the first roller 11 and the second roller 12, and then winds on the second roller 12. The outer wall surface of the test paper 7 wipes the sample in the sampling interval. The sample is adsorbed on the outer wall of the test paper 7; when the part of the...

Embodiment 2

[0079] This embodiment provides a sample supply system for conveying gas, including the continuous wiping sampling device in Embodiment 1 and a thermal desorber 6 . The sample inlet 61 of the thermal analyzer 6 is opposite to the sample unloading section of the continuous wiping sampling device, and the thermal analyzer 6 sucks the samples on the outer wall surface of the test paper 7 in the sample unloading section into the thermal analyzer 6 .

[0080] For example, the sample is a particle or powder, and the sample is sucked into the thermal desorption instrument 6 from the sample inlet 61, and the sample is pyrolyzed into a gaseous state in the thermal desorption instrument 6, and the gaseous sample enters the detection from the gas outlet 62 of the thermal desorption instrument 6 along with the air. The device is tested. After the test paper 7 is wiped and sampled, the thermal analysis sample is directly injected. The moving position of the test paper 7 is short, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com