Fitness evaluation method for high-sulfur natural gas pipeline material in service

A technology for evaluating the adaptability of natural gas pipelines, which is applied in the field of material adaptability evaluation of in-service high-sulfur natural gas pipelines, can solve problems such as the difficulty of direct evaluation, achieve easy understanding and practical operation, ensure safe production, and have a simple mathematical model Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

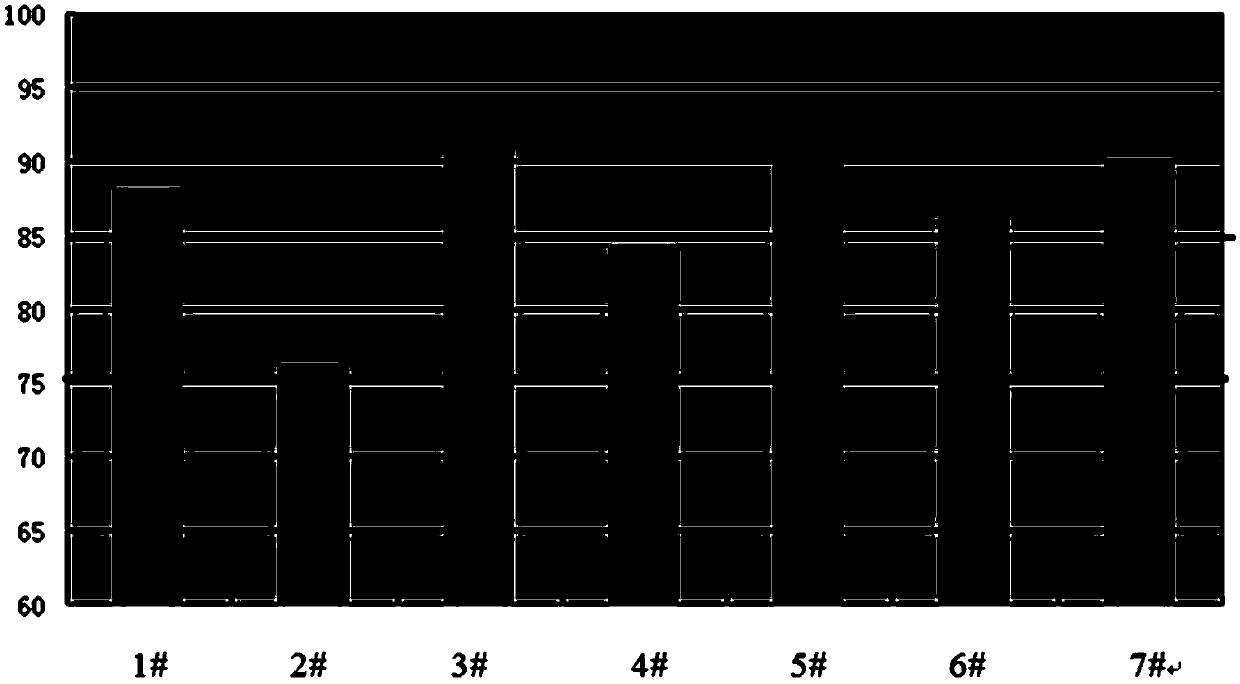

Examples

Embodiment Construction

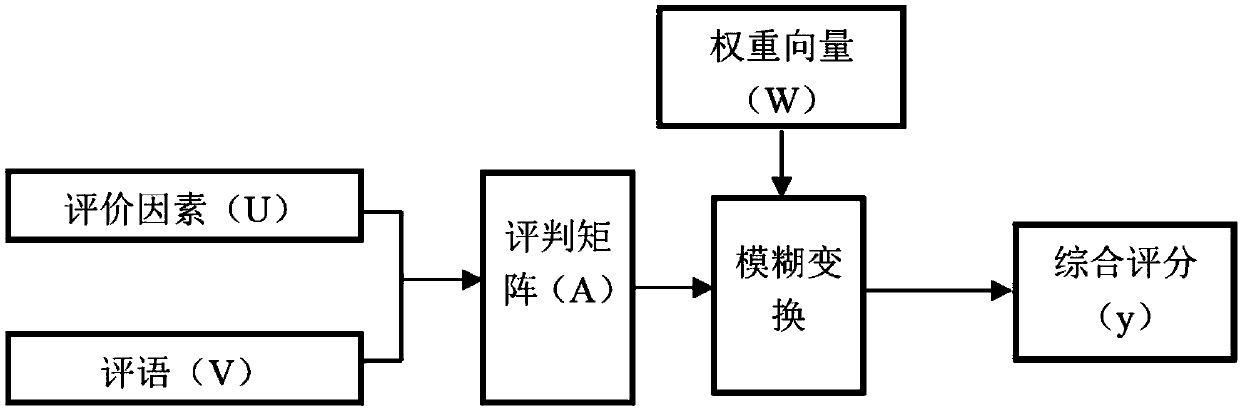

[0045] The invention provides a method for evaluating the adaptability of the materials of in-service high-sulfur natural gas pipelines, which combines the corrosion status of in-service natural gas pipeline materials, the aging degree of physical and chemical properties after sampling, the test of sulfur resistance and corrosion resistance after sampling, and the corrosion protection on the service site Measures and other evaluation indicators, through the fuzzy multi-level comprehensive evaluation method to evaluate the service adaptability and safety of pipeline materials, the evaluation results are closer to the objective reality, so that pipeline managers can have a clear and accurate understanding of the service status of high-sulfur natural gas pipelines in service understanding and guiding actual production issues.

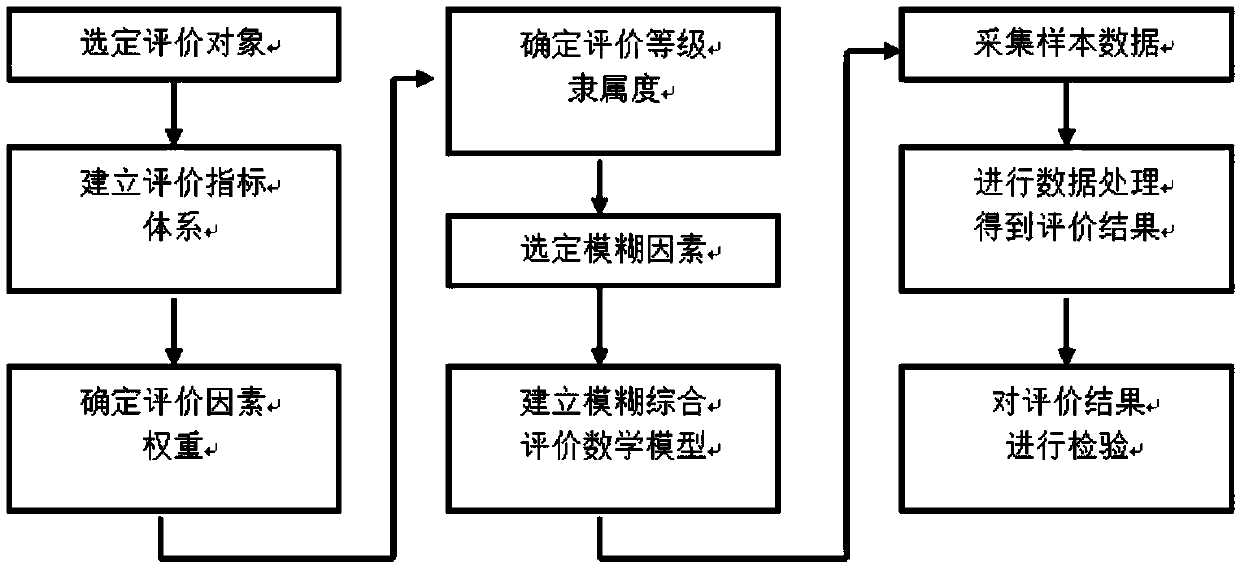

[0046] see figure 1 , a method for evaluating the material adaptability of in-service high-sulfur natural gas pipelines in the present invention, first es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com