A cylinder cover partition fatigue life estimation method

A fatigue life, cylinder head technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not being able to effectively meet the cylinder head fatigue assessment, and not being able to accurately and effectively calculate the cylinder head fatigue life, to achieve The effect of reducing bias problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0048] The present invention will be described in detail below with reference to the accompanying drawings and examples.

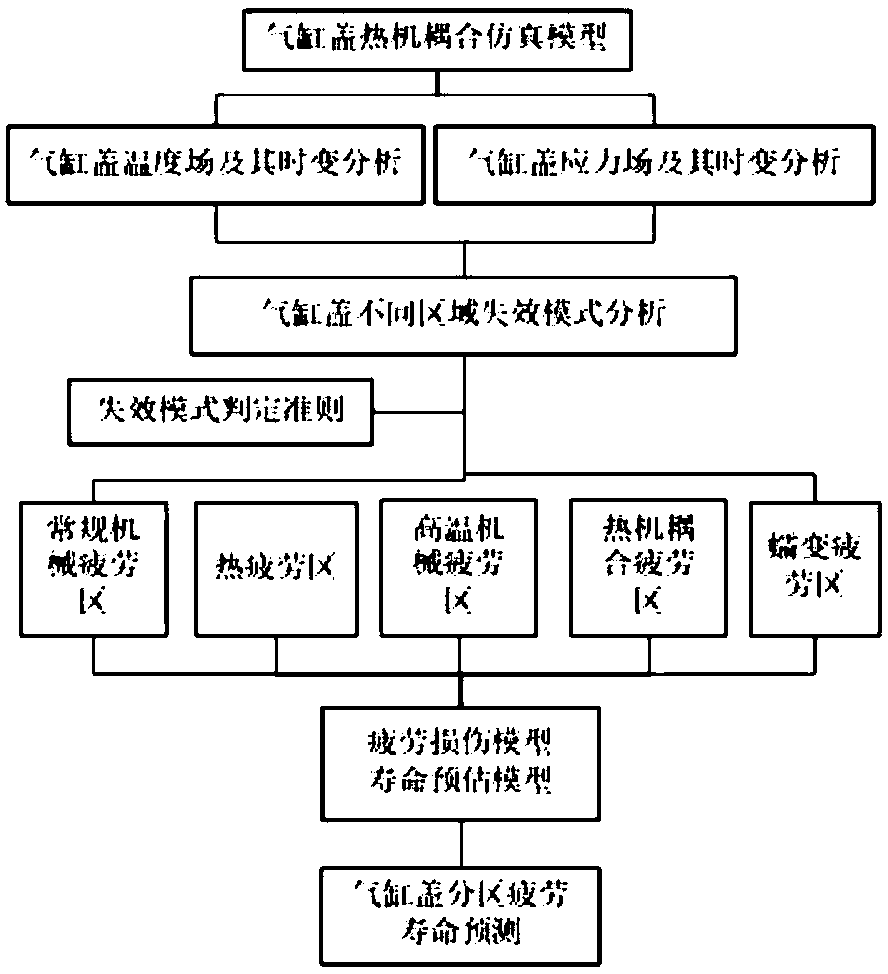

[0049] 1, a kind of engine cylinder head fatigue life estimation method is characterized in that comprising the following steps:

[0050] a. Obtain the cylinder head temperature field through temperature measurement test or finite element simulation method

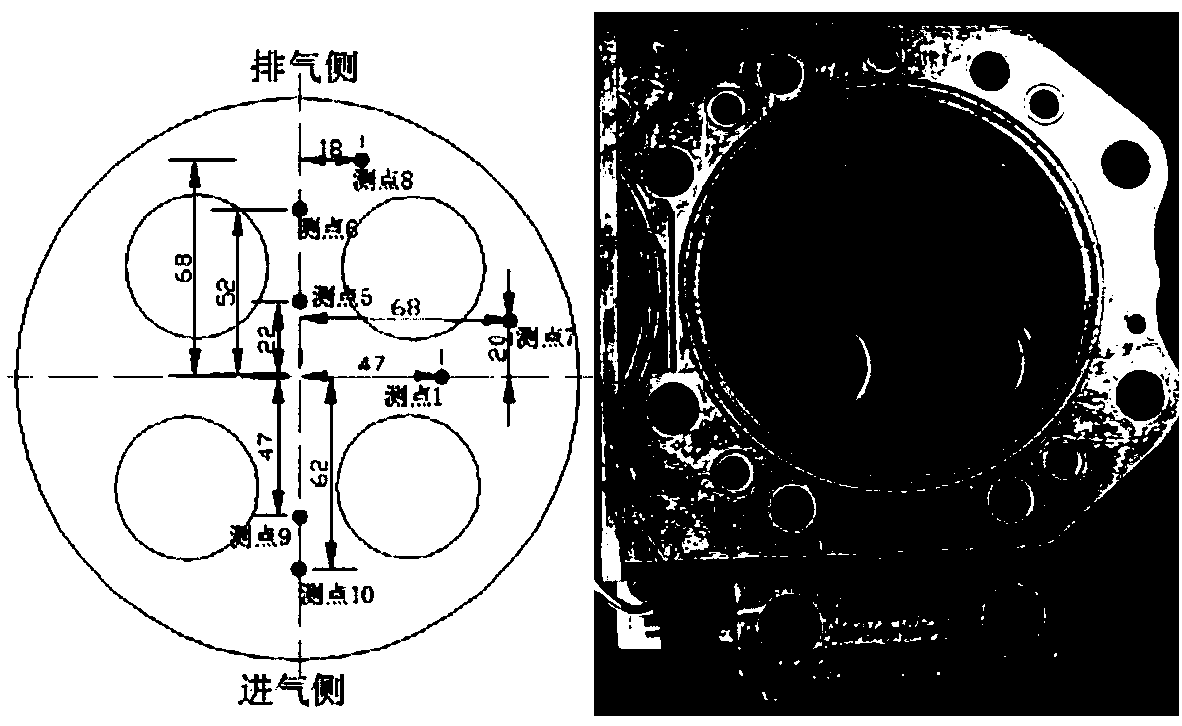

[0051] For example: the main high-temperature area of the cylinder head is on the bottom surface, and the temperature measurement test of a certain cylinder head determines that the measuring points on the bottom surface are as follows: figure 2 As shown, temperature sensors are used to determine the temperature of each point; or through combustion heat transfer analysis and finite element fluid-solid coupling analysis; or by usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com