Spiral connection structure-based power system

A technology of screw connection and power supply system, which is applied in the parts, connection, clamping/spring connection and other directions of the connection device, which can solve the problem of difficult to ensure the stability and reliability of the electrical connection between the power module and the backplane, poor contact, Affect normal use and other problems, to avoid poor contact and ensure close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

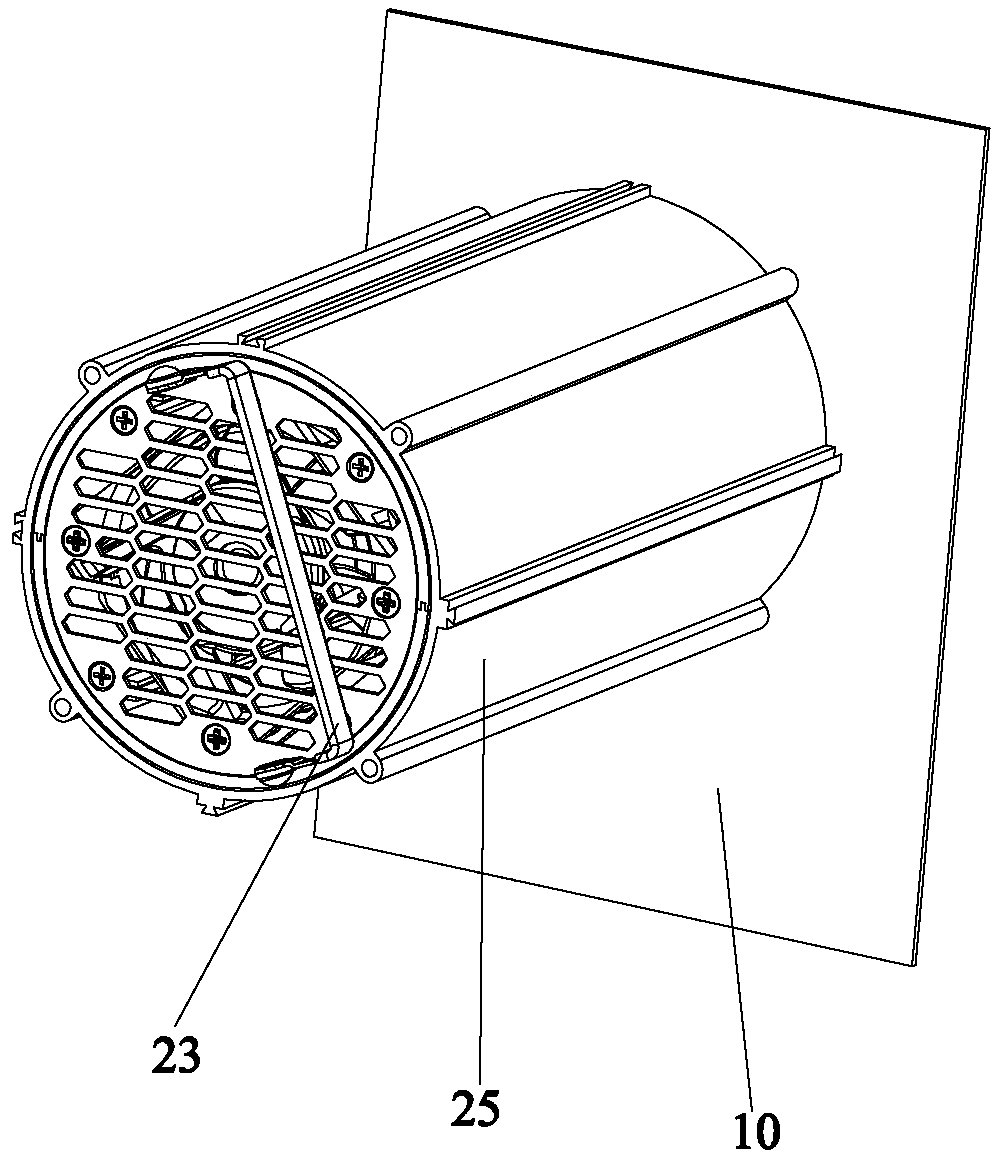

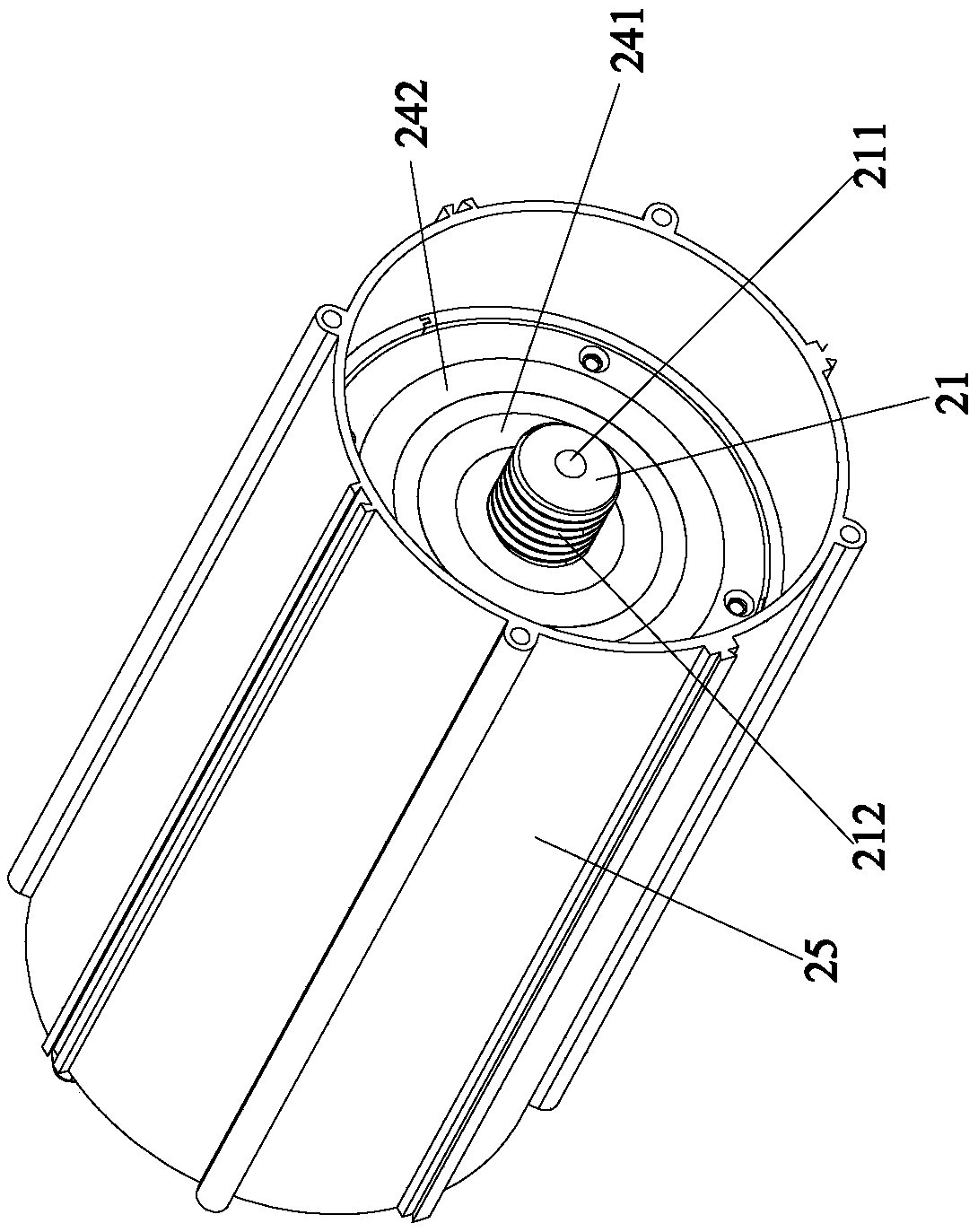

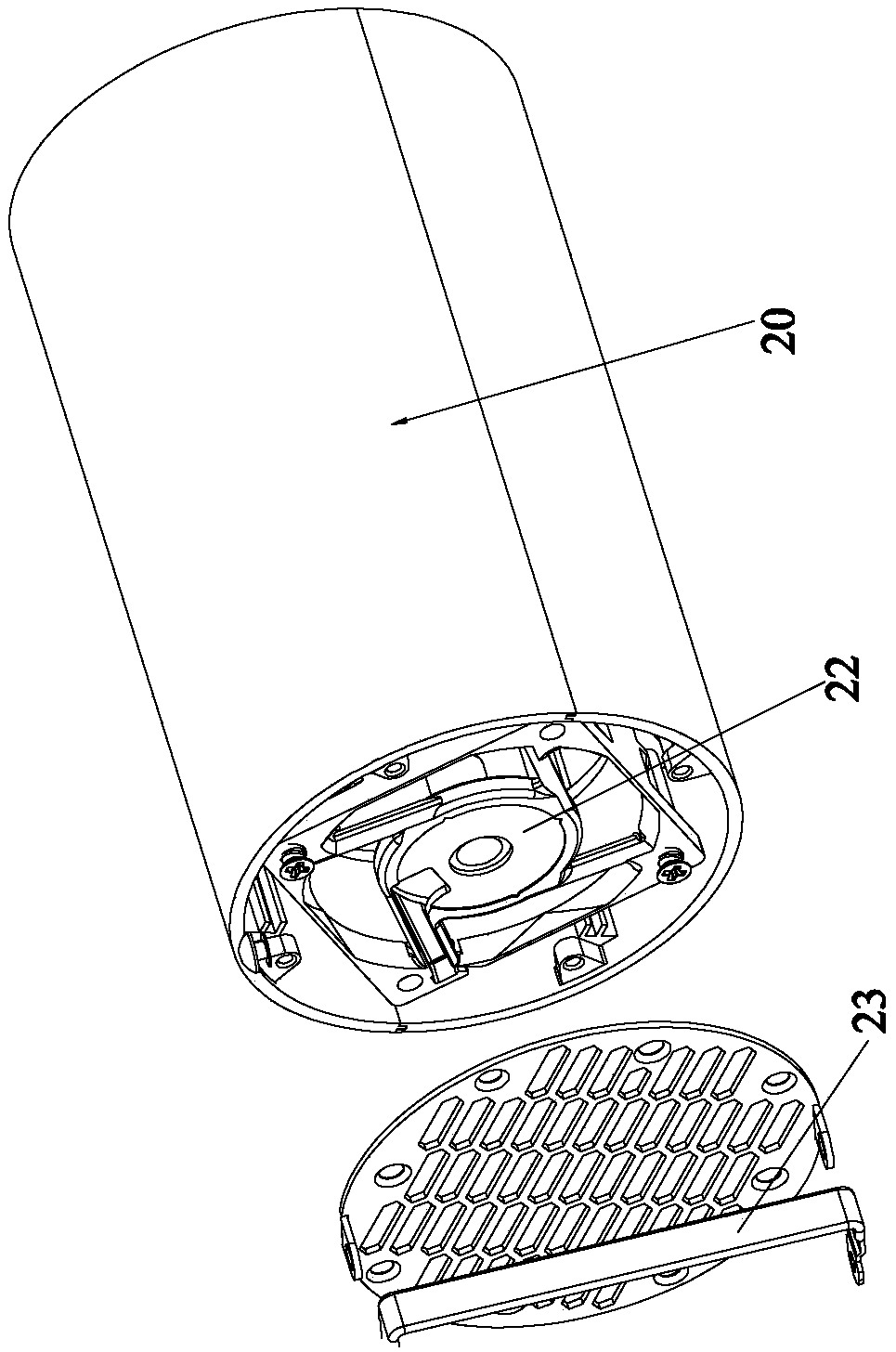

[0041] like Figure 1 to Figure 6 As shown, a power supply system based on a screw connection structure includes a backplane 10 and a power supply module 20, wherein:

[0042] In this embodiment, the power module 20 is an AC-DC power module. The power module 20 has a protruding post 21 , a first DC contact end, a handle 23 and a fan 22 , and the handle 23 is disposed on the opposite side of the protruding post 21 . The protruding post 21 is provided with a first AC contact end 211 , and the back plate 10 has a second DC contact end and a second AC contact end 11 ; the protruding post 21 is screwed with the back plate 10 to achieve the first The AC contact terminal 211 is electrically connected to the second AC contact terminal 11 , and at the same time, the first DC contact terminal is electrically connected to the second DC contact terminal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com