Electrothermal film with PTC effect and preparation method

A technology of electric heating film and effect, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts and other directions, can solve the problems of high development cost and long development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a method for preparing the above electrothermal film, comprising the following steps:

[0036] Prepare the third component particles containing conductive filler: mix the conductive filler and the third component at a weight ratio of 40-90:30-60, add to a screw extruder to melt and extrude, cool, granulate, and pulverize, That is, the third component particles containing conductive fillers;

[0037]Specifically, carbon black is mixed with the third component in a ratio of 40-90:30-60 by weight, and added to the screw extruder, and the temperature settings in each zone of the screw extruder should be higher than the melting point of the third component. -30°C. Then carry out melt extruding, through the steps of cooling and granulation to obtain slices containing carbon black, then pulverize the slices with a pulverizer, and use multi-layer sieves with different meshes to sieve to obtain carbon black-containing and The third component part...

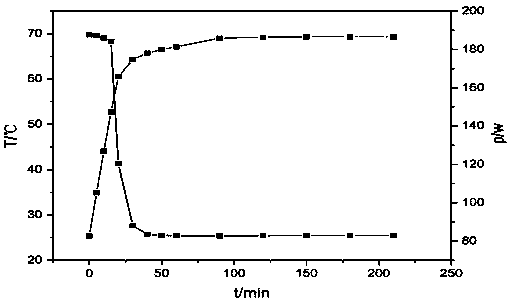

Embodiment 1

[0048] Preparation of third component microparticles containing carbon black

[0049] The carbon black used had an average diameter of 15 nm. Mix 600 grams of carbon black with 400 grams of microcrystalline wax powder and add it to a twin-screw extruder with 6 temperature zones. ℃, 82℃. The screw speed is adjusted according to the screw outlet pressure, and the outlet pressure is kept at 5-10Mpa. The screw extruder is directly connected to the cooling granulator, and after granulation, slices containing carbon black are obtained. The slices were pulverized with an electric pulverizer, and sieved by a sieve machine with three layers of screens, the screens were 50 mesh, 200 mesh and 300 mesh respectively, and the third component particles with a mesh number of 200-300 mesh were collected.

[0050] Preparation of conductive carbon paste

[0051] In the reactor equipped with stirring device, add 200 grams of carbon black-containing particles prepared in the first step, the si...

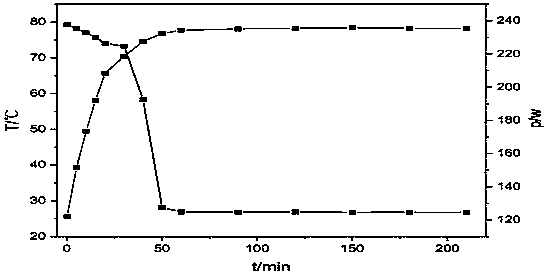

Embodiment 2

[0056] The difference from Example 1 is that when preparing the third component particles containing carbon black, the third component used is PMMA; the temperature settings of each zone of the screw extruder are: 95°C, 100°C, 100°C, 100°C °C, 100 °C, 97 °C.

[0057] All the other steps are the same as in Example 1.

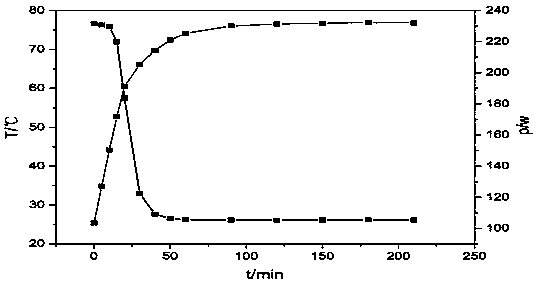

[0058] The finished product in this embodiment is subjected to a performance test, and the results of the power-on test are shown in the attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com