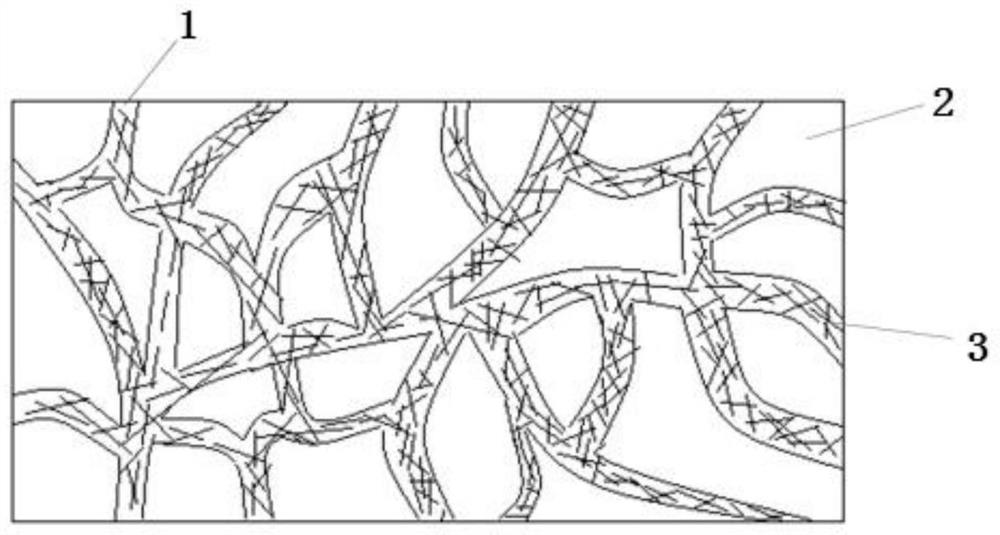

A kind of electrothermal film with PTC effect and preparation method thereof

An electrothermal film and effect technology, applied in electrothermal devices, ohmic resistance heating, electrical components, etc., can solve problems such as difficulty in achieving PTC effect, poor mechanical properties, poor dimensional stability, and poor film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation steps and formula of this embodiment are as follows:

[0044] 1. Hydrophilic surface treatment of carbon fiber short fibers: the carbon fiber short fibers used have a length of 150 microns and a diameter of 7 microns. Get 100 grams of carbon fiber short fiber and add it to deionized water to immerse the carbon fiber, and treat it ultrasonically for 30 minutes; place the carbon fiber after the ultrasonic treatment in a solution of Tris (Tris) to immerse the carbon fiber, and the tris in the solution The concentration of methane is 0.015 mol / liter; add 40 g of dopamine hydrochloride and stir to dissolve the dopamine hydrochloride; add 1 mol·L-1 of HCl to adjust the pH of the solution to 8.5; stir at room temperature and allow it to react for 20 hours. Finally, the surface-treated short carbon fiber is repeatedly rinsed with deionized water until the washing liquid is colorless, and then the short carbon fiber is dried to obtain the short carbon fiber whose...

Embodiment 2

[0049] Different from Example 1, in the second step, it is:

[0050] 2. Prepare conductive carbon paste: in the reactor equipped with stirring device, add 21 grams of short carbon fiber through dopamine surface treatment, then add 37.4 grams of poly(N-isopropylacrylamide), and add 30 grams of water, Stir until the carbon fibers can be uniformly dispersed in the mixing system without settling, and the conductive carbon paste is prepared.

[0051] All the other steps are the same as in Example 1.

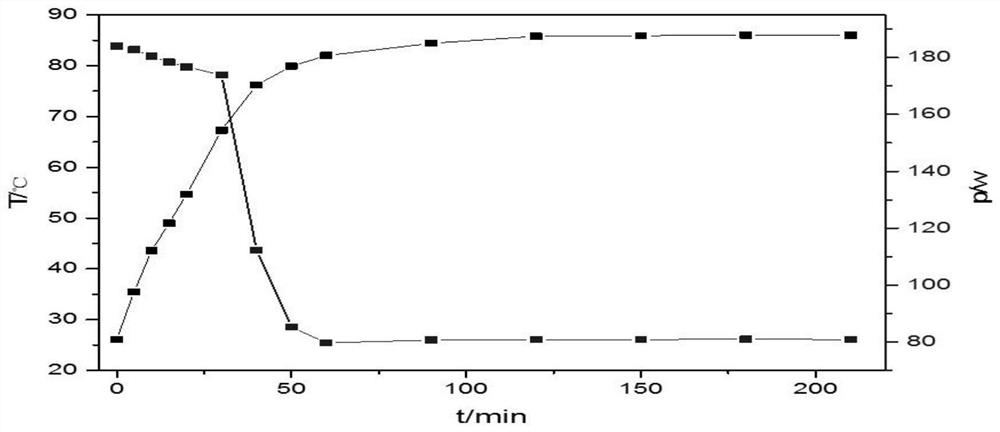

[0052] The finished product in this embodiment is subjected to a performance test, and the results of the power-on test are shown in the attached image 3 .

Embodiment 3

[0054] Different from Example 1, in the second step and the third step, it is:

[0055] 2. Preparation of conductive carbon paste: In a reaction kettle equipped with a stirring device, add 21 grams of carbon fiber short fibers treated with dopamine surface, then add 47 grams of polymethacrylamide, and add 30 grams of water, stir to prepare conductive carbon paste .

[0056] 3. Preparation of electric heating film: add 100 grams of prepared conductive carbon paste to 190 grams of polyurethane emulsion, the solid content of polyurethane emulsion is 50%, and stir for 30 minutes; operate the coating machine to coat on the non-woven fabric, coating The thickness is 120μm, and it is dried after coating.

[0057] All the other steps are the same as in Example 1.

[0058] The finished product in this embodiment is subjected to a performance test, and the results of the power-on test are shown in the attached Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com