Double nasal oxygen cannula direct oxygen feeding method and double nasal oxygen cannula

The technology of double nasal oxygen tube and nasal oxygen tube is applied in the field of medical devices, which can solve the problems of inability to guarantee stable and smooth oxygen supply, high production cost and labor consumption, and low bending resistance, and achieves the guarantee of smoothness, Enhanced compressive and flexural properties and reduced residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings, but the present invention is not limited to the following embodiments.

[0024] A double-connected nasal oxygen tube direct oxygen intake method, comprising the following steps:

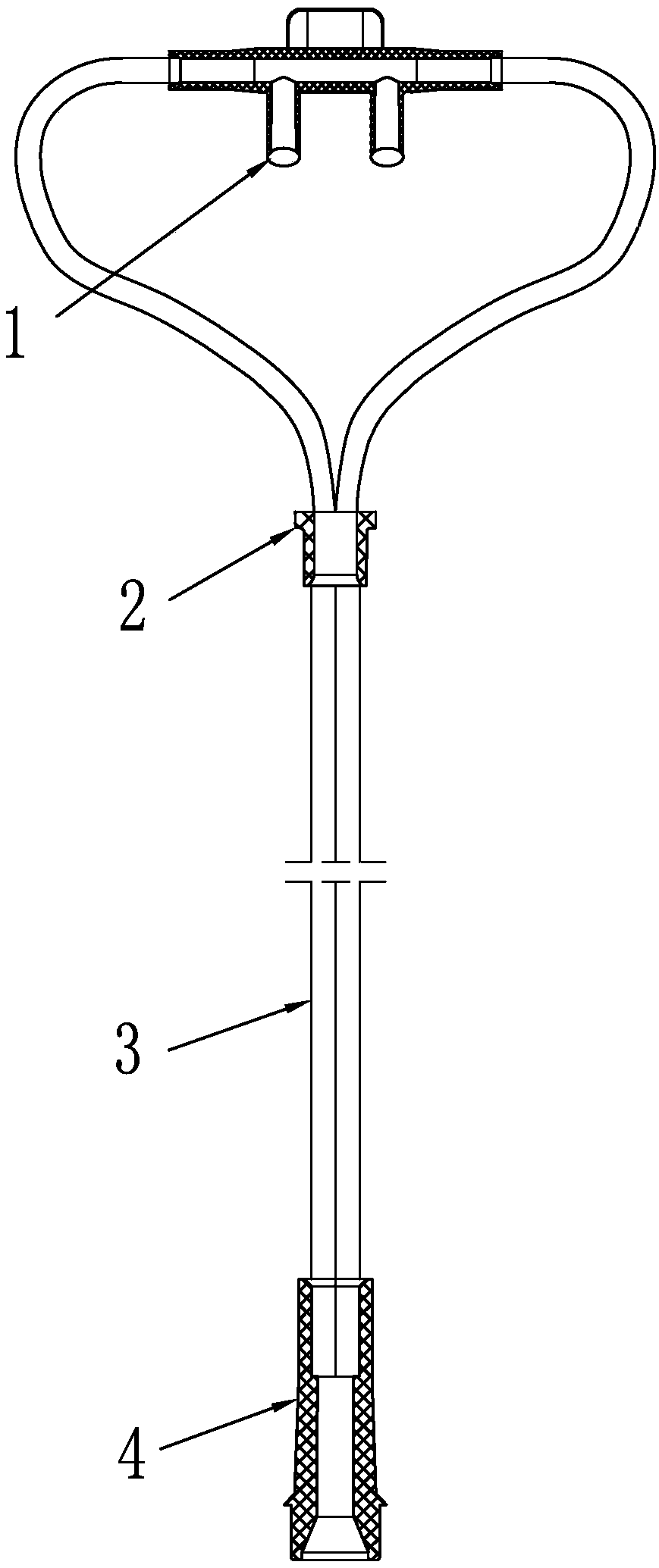

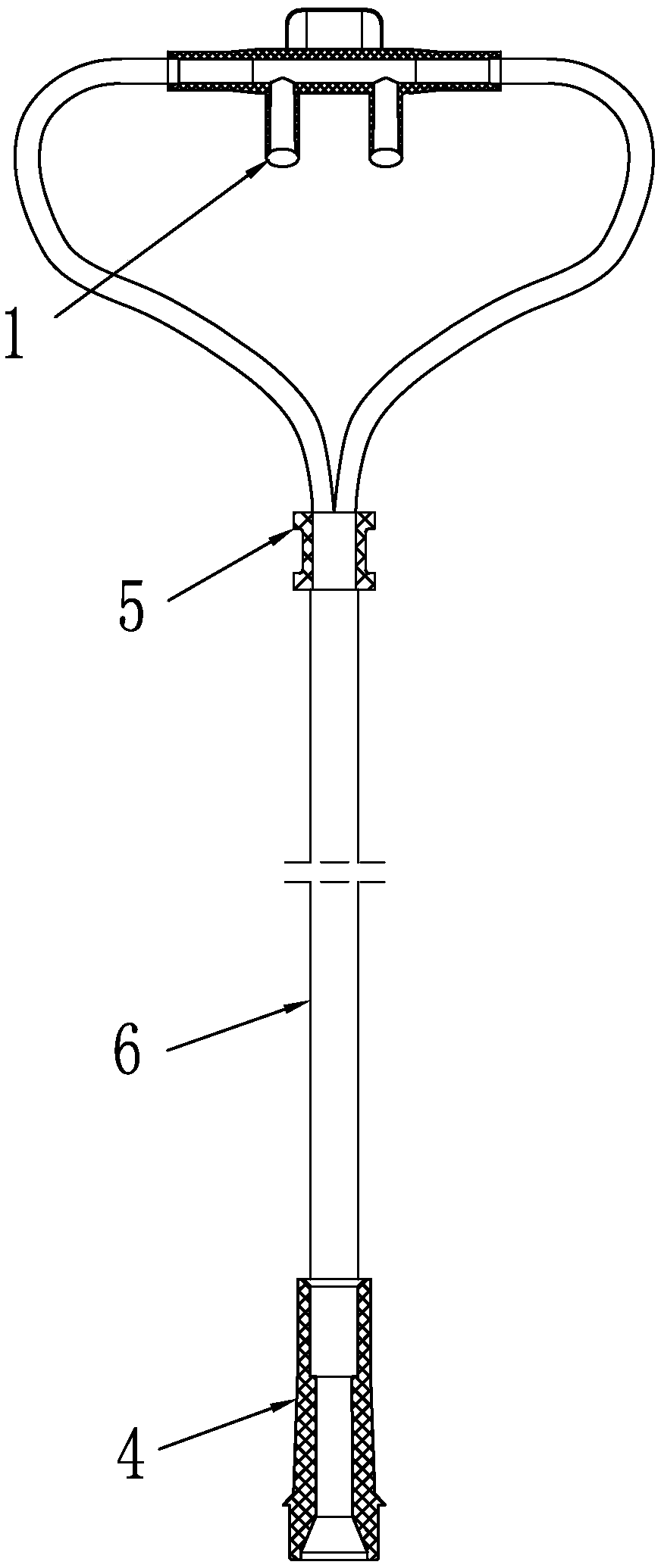

[0025] 1) Connect one end of the two small tubes directly to an oxygen source (such as bottled oxygen) to introduce oxygen through the joint 4 (the joint is a conventional part that can be purchased), and the other end of the two small tubes is connected to the nasal plug 1 to serve as an air supply to the patient end; the nasal plug is also a conventional part that can be purchased; it can be figure 1 The shown double-tube nasal plug (oxygen delivery to two nostrils) can be single tube nasal plug (only oxygen delivery to one nostril).

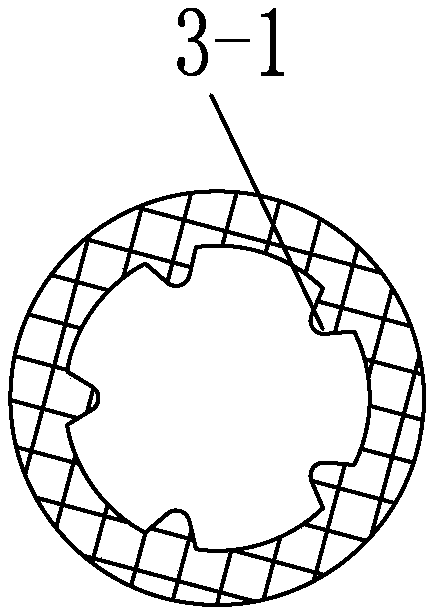

[0026] 2) The inner walls of the two small tubes are evenly distributed with several reinforcing ribs 3-1 ( figure 2 There are 5 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com