Piezoelectric injection valve with symmetrical structure layout

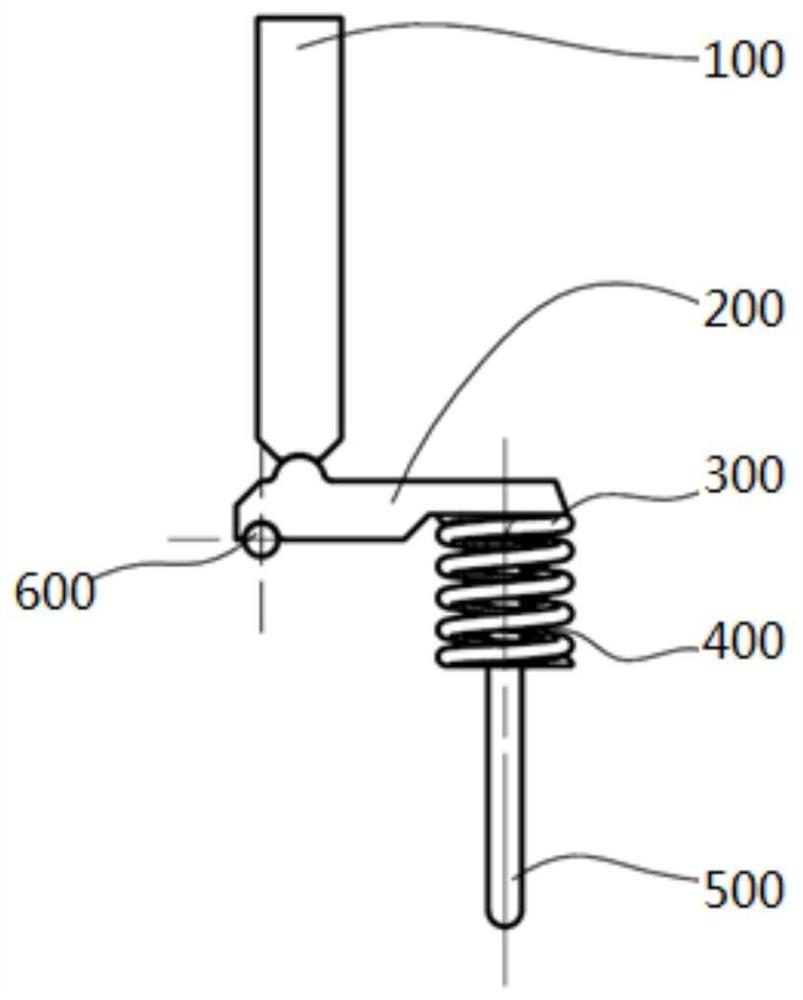

A technology of structural layout and piezoelectric injection, which is applied to the device and coating of the surface coating liquid, can solve the problems of reciprocating motion striker parts wear, malfunction, glue-hanging of the dispensing valve, etc., to avoid output The loss of displacement and output force, the improvement of glue performance, and the effect of optimized composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

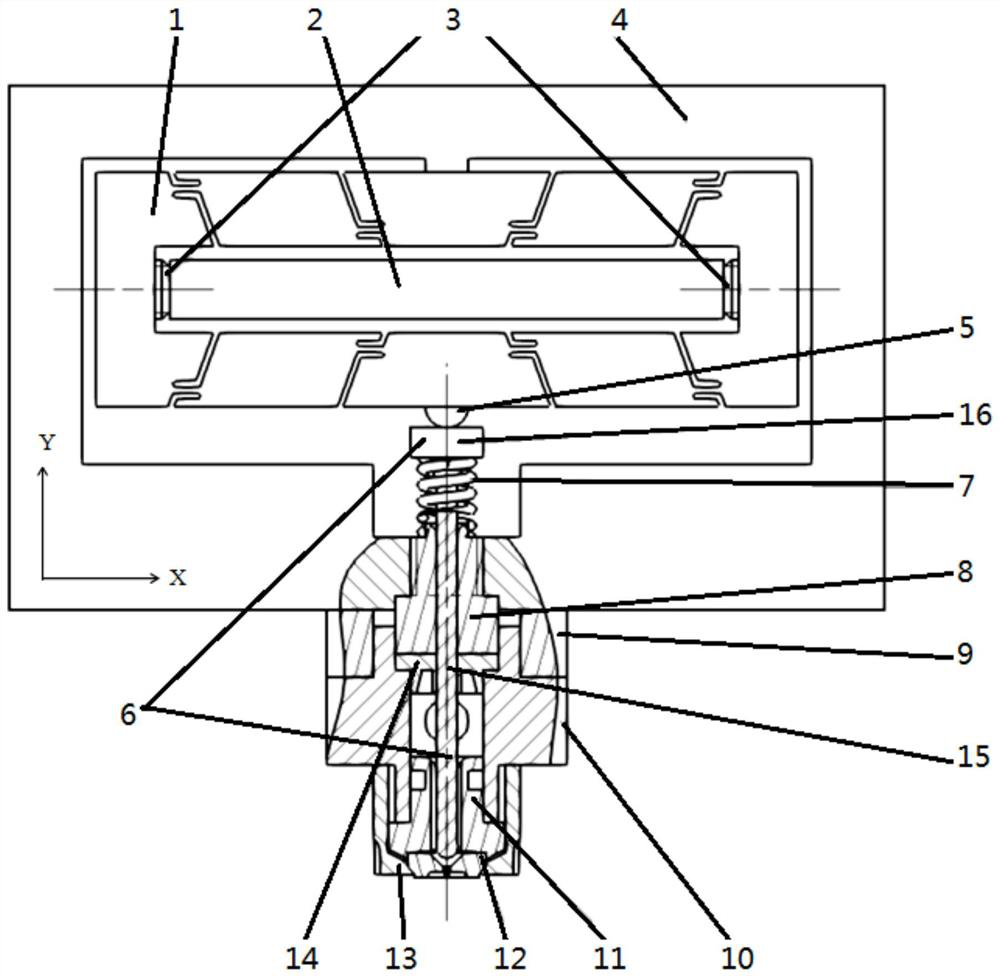

[0032] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

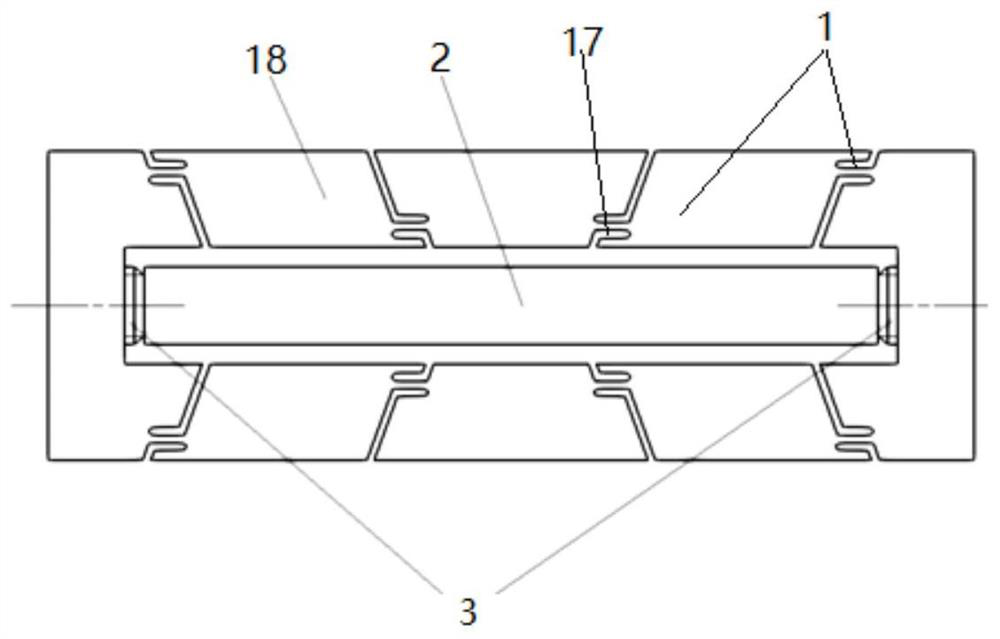

[0033] An embodiment of the present invention provides a piezoelectric injection valve with a symmetrical structural layout, such as Figure 2-4 As shown, the valve body 4 is included, and the valve body 4 is provided with a symmetrical multi-stage multi-hinge amplification mechanism 1 and a striker 6, wherein:

[0034] Symmetrical multi-stage multi-hinge amplification mechanism 1 is symmetrical in the horizontal and vertical directions, image 3 The X-axis direction is the horizontal direction, and the Y-axis direction is the vertical direction. A multi-layer piezoelectric ceramic 2 is horizontally arranged in the symmetrical multi-stage multi-hinge amplification mechanism 1, and the multi-layer piezoelectric ceramic is placed horizontally in the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com