Preparation method and processing mold of aluminum alloy special-shaped sheet metal parts for rail transit

A technology for processing molds and rail transit, applied in the field of precision sheet metal processing, can solve the problems of difficult shape precision processing control, thin wall thickness, poor surface quality, etc., to improve the preparation and forming ability, increase the overall rigidity, and reduce the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

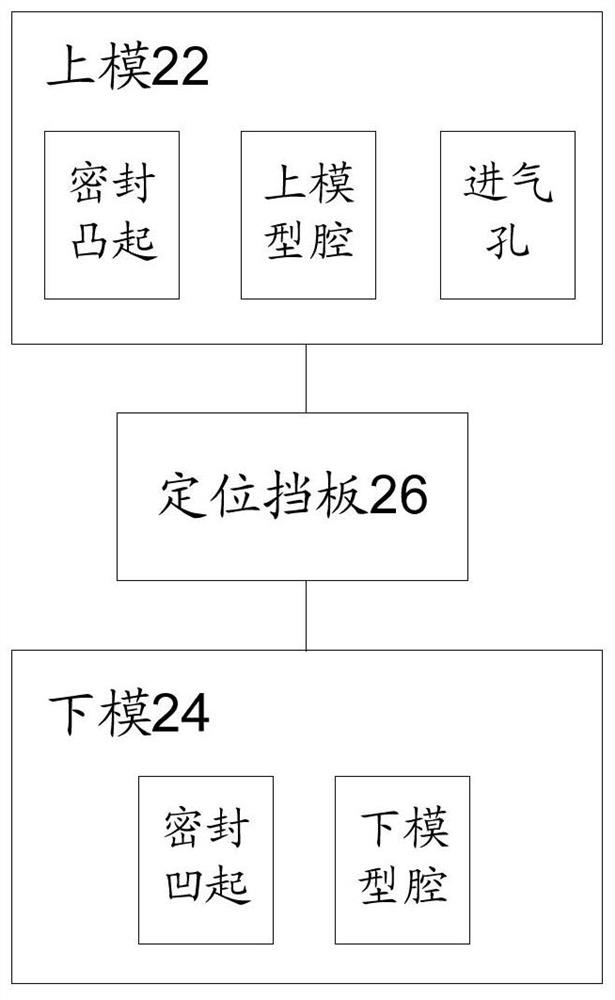

[0030] In order for those skilled in the art to better understand the solutions of the present invention, the embodiments of the present invention will be described below with reference to the accompanying drawings.

[0031] According to an embodiment of the present invention, an embodiment of a method for preparing an aluminum alloy special-shaped sheet metal part for rail transit is provided. It should be noted that although a logical sequence is shown in the flowchart, in some cases, Steps shown or described may be performed in an order different from that herein.

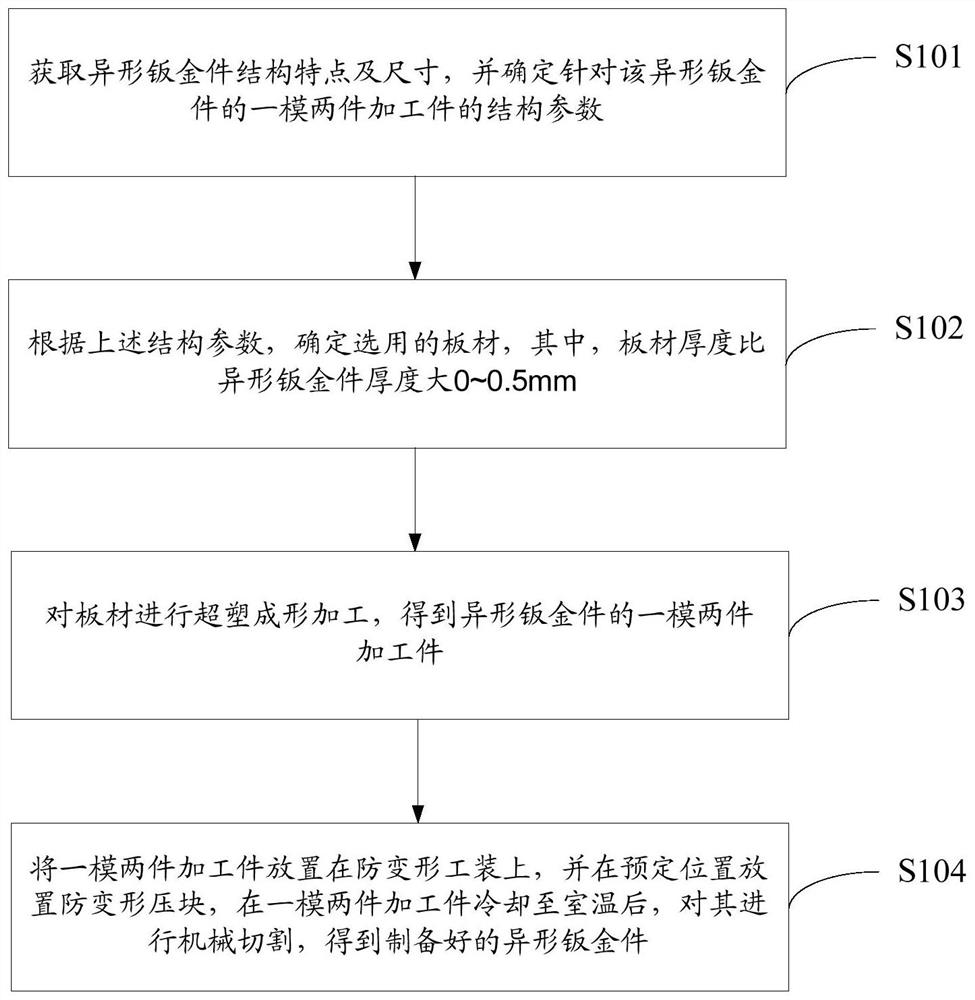

[0032] figure 1 It is a flow chart of a method for preparing an aluminum alloy special-shaped sheet metal part for rail transit according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

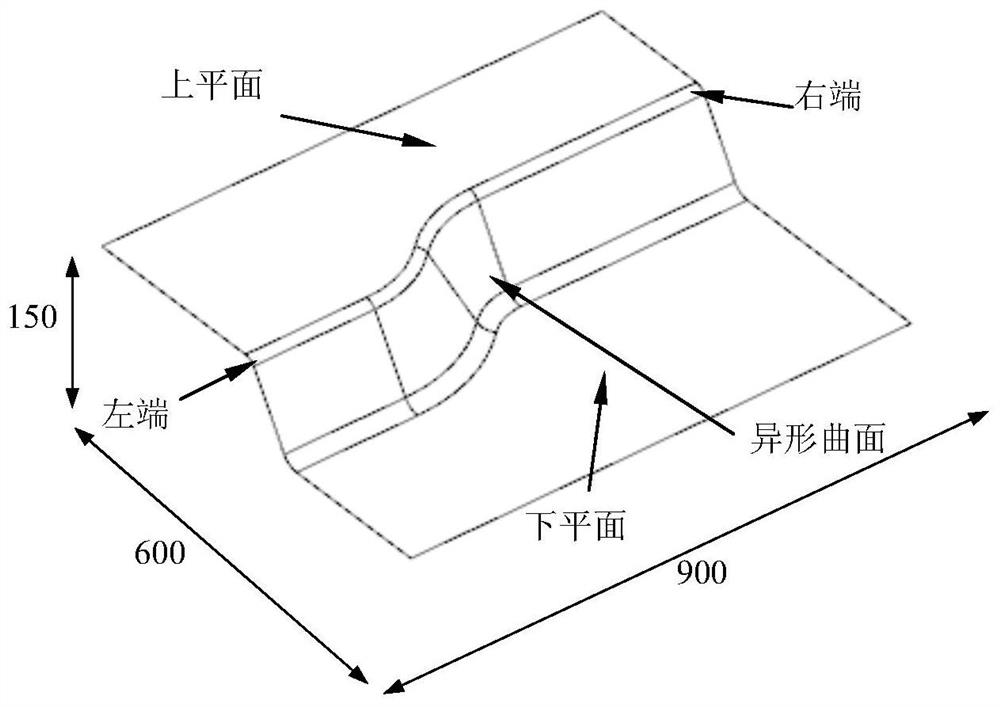

[0033] In step S101, the structural characteristics and dimensions of the special-shaped sheet metal part are obtained, and the structural parameters of the one-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com