Special equipment for milling machine for processing small-sized parts and its use method

A technology with small size and equipment, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as lack of adaptability, safety hazards, easy to damage the surface of parts, etc., to avoid safety hazards, reduce work intensity, The effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

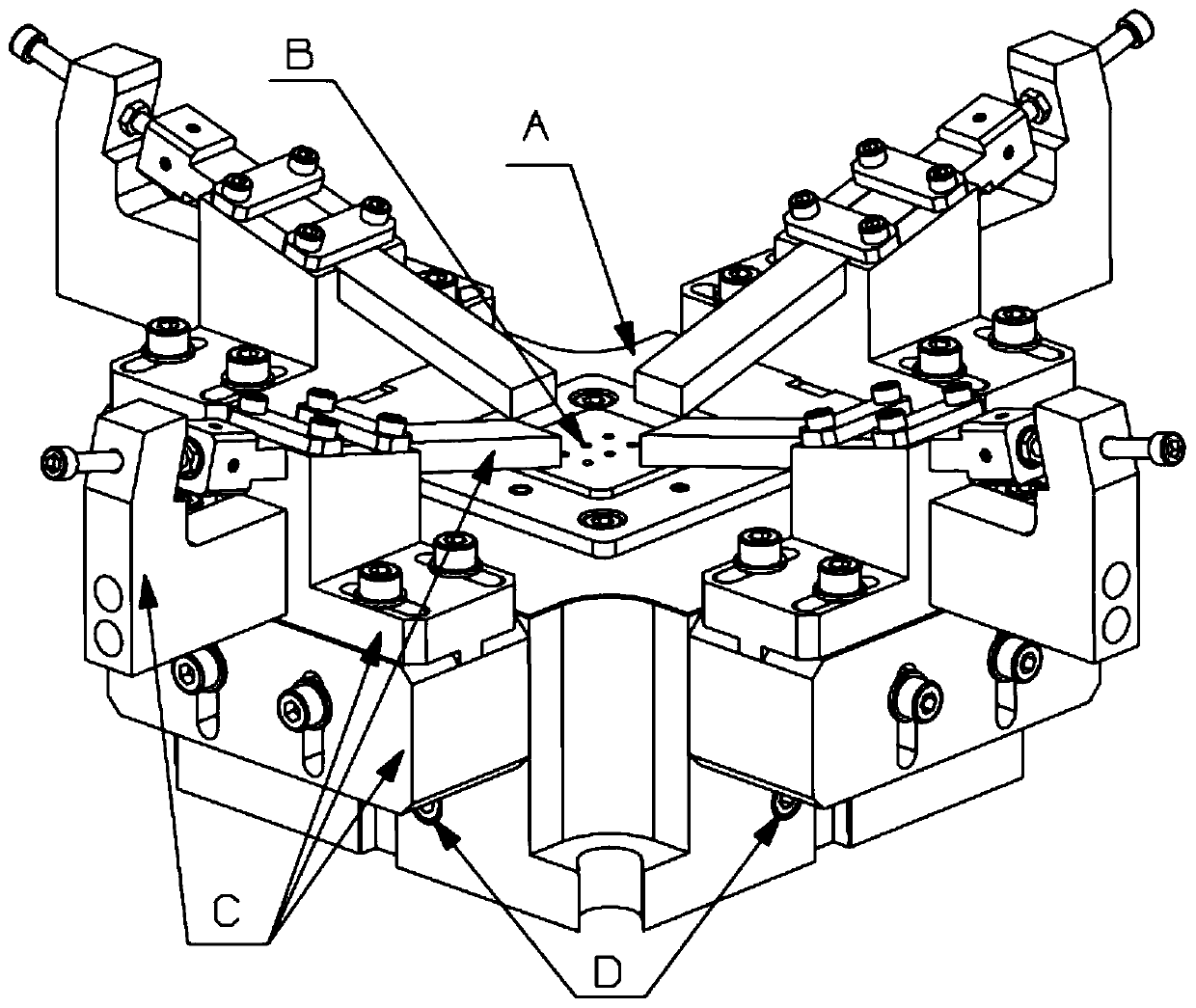

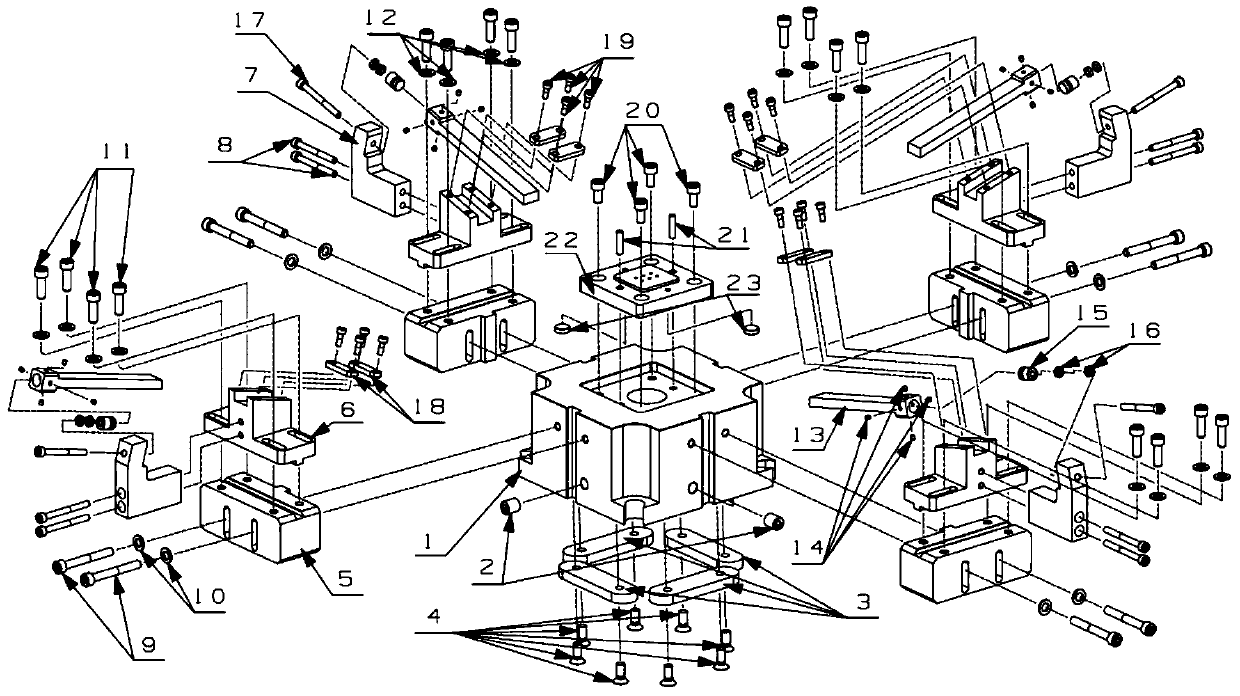

[0036] Embodiment 1: as Figure 1-3 As shown, a milling machine special equipment for processing parts, including a combined base body A, an interchangeable positioning panel B, and a displacement positioning system C; wherein the interchangeable positioning panel B is installed on the rounded rectangle at the top of the combined base body A In the inner tank, four sets of displacement positioning systems C are symmetrically installed around the combined base body A, and the installation of this equipment and the milling machine is completed through the combined base body A.

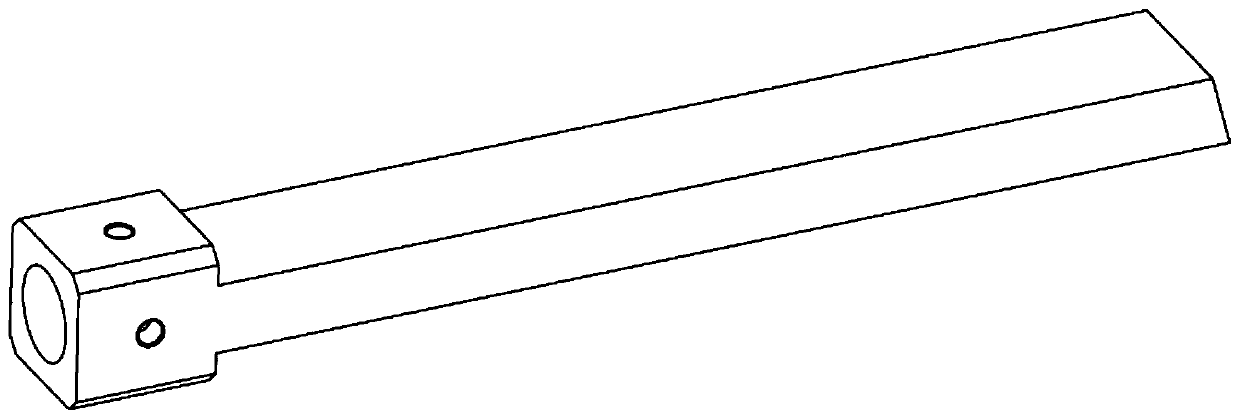

[0037] Further, it can be set that the combined base body A includes an air guide base 1, and the top of the air guide base 1 is provided with a rounded rectangular inner groove and is fixedly installed with the base panel 22 in the interchangeable positioning panel B; The outer peripheral surface of the base 1 is provided with a vertical guide groove to match and install the vertical guide block 5 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com