Ball bladder center line polishing device

A technology for the center line of the bladder and the bladder, which is applied to the grinding drive device, grinding/polishing safety device, grinding machine, etc. The effect of partial, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

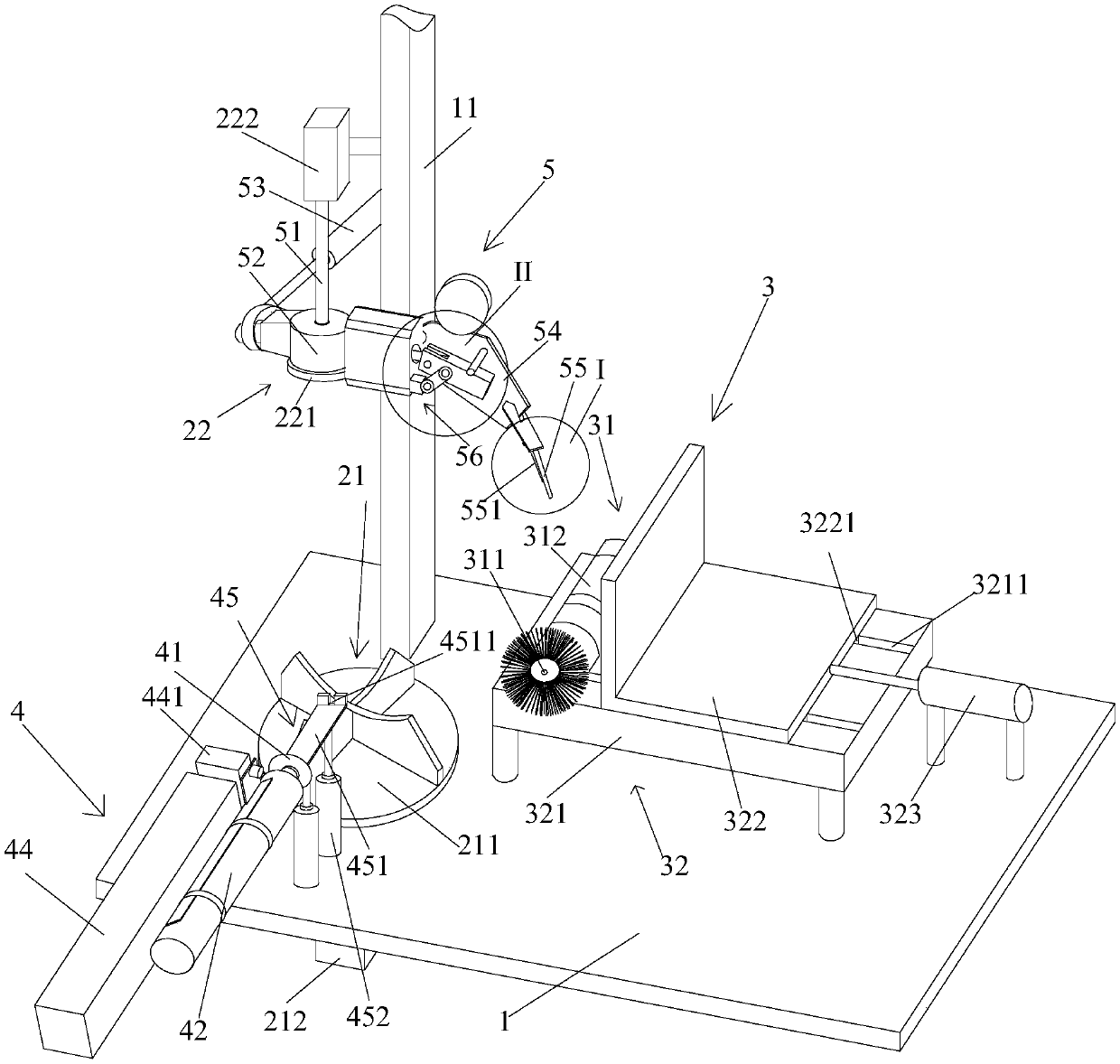

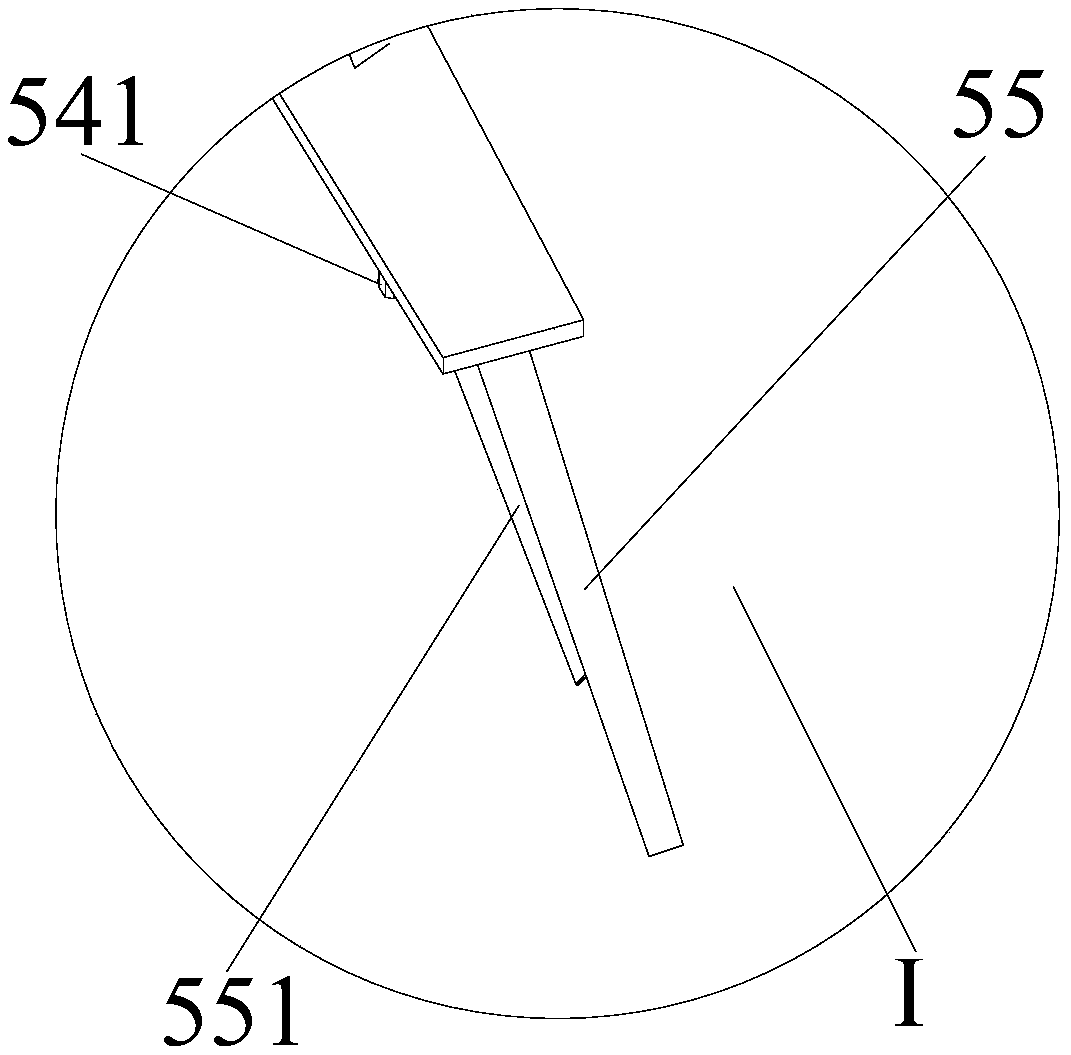

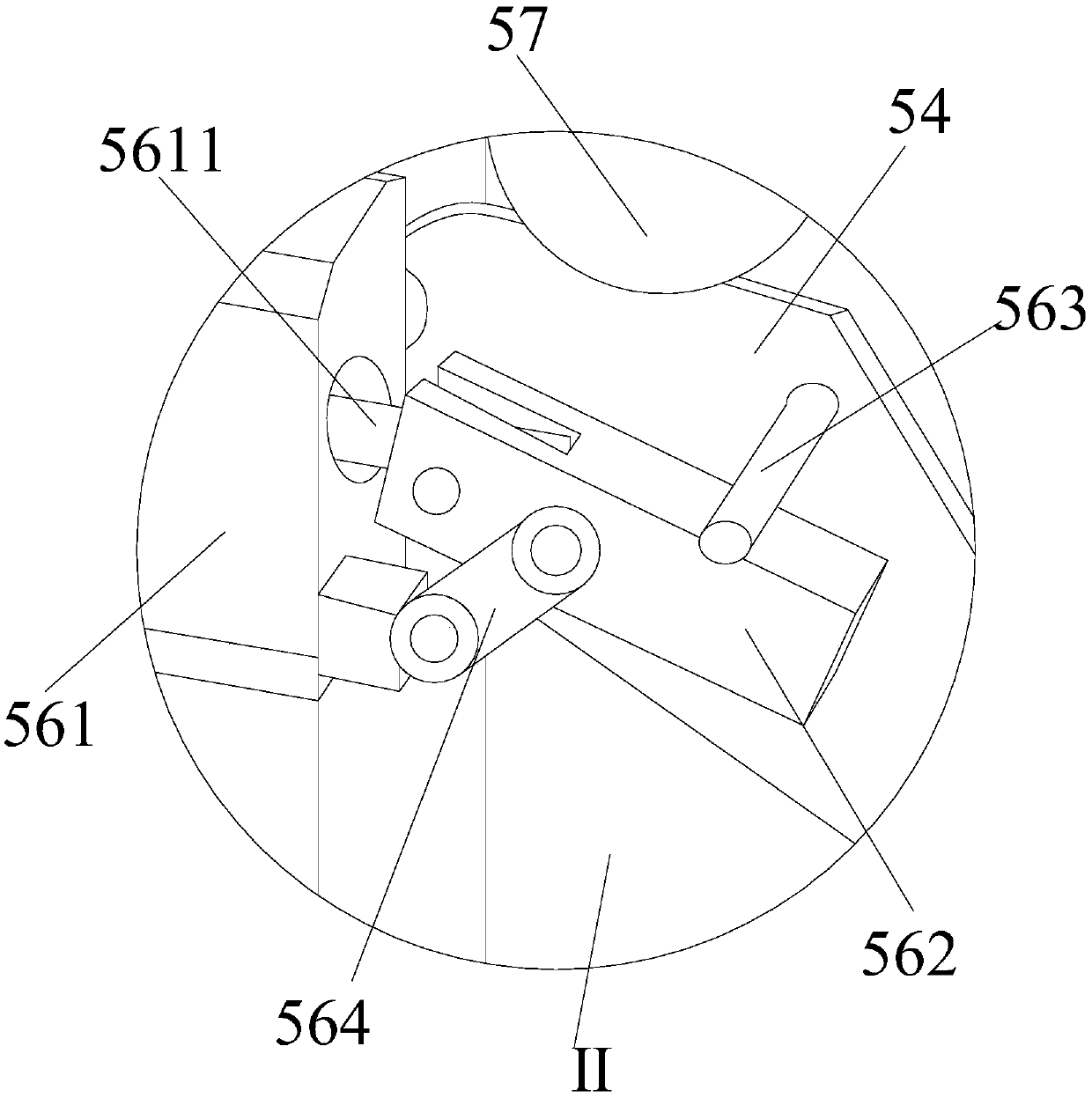

[0025] like Figure 1 to Figure 9 Shown is a schematic diagram of an embodiment of a ball bladder midline grinding device provided by the present invention. like Figure 10 Shown is a schematic diagram of the structure of a basketball bladder.

[0026] The centerline grinding device of the bladder comprises an operating platform 1, a rotating mechanism for placing the bladder 6 on the operating platform 1 and controlling the rotation of the bladder 6 around its longitudinal central axis, and a centerline 63 for grinding the bladder on the operating platform 1. grinding mechanism A3;

[0027] The grinding mechanism A3 includes a grinding assembly A31 located on the right side of the rotating mechanism; the grinding assembly A31 includes a grinding wire brush 311 and a driving unit A that is connected with the grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com