Lifting appliance for lifting and production machining method thereof

A processing method and technology of a spreader, which are applied in the directions of load hanging components, transportation and packaging, etc., can solve the problems affecting construction efficiency and construction safety, low bolt fixing safety, inconvenient installation and unloading, etc., and achieve improved performance and safety. Long service life, improved fatigue strength and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

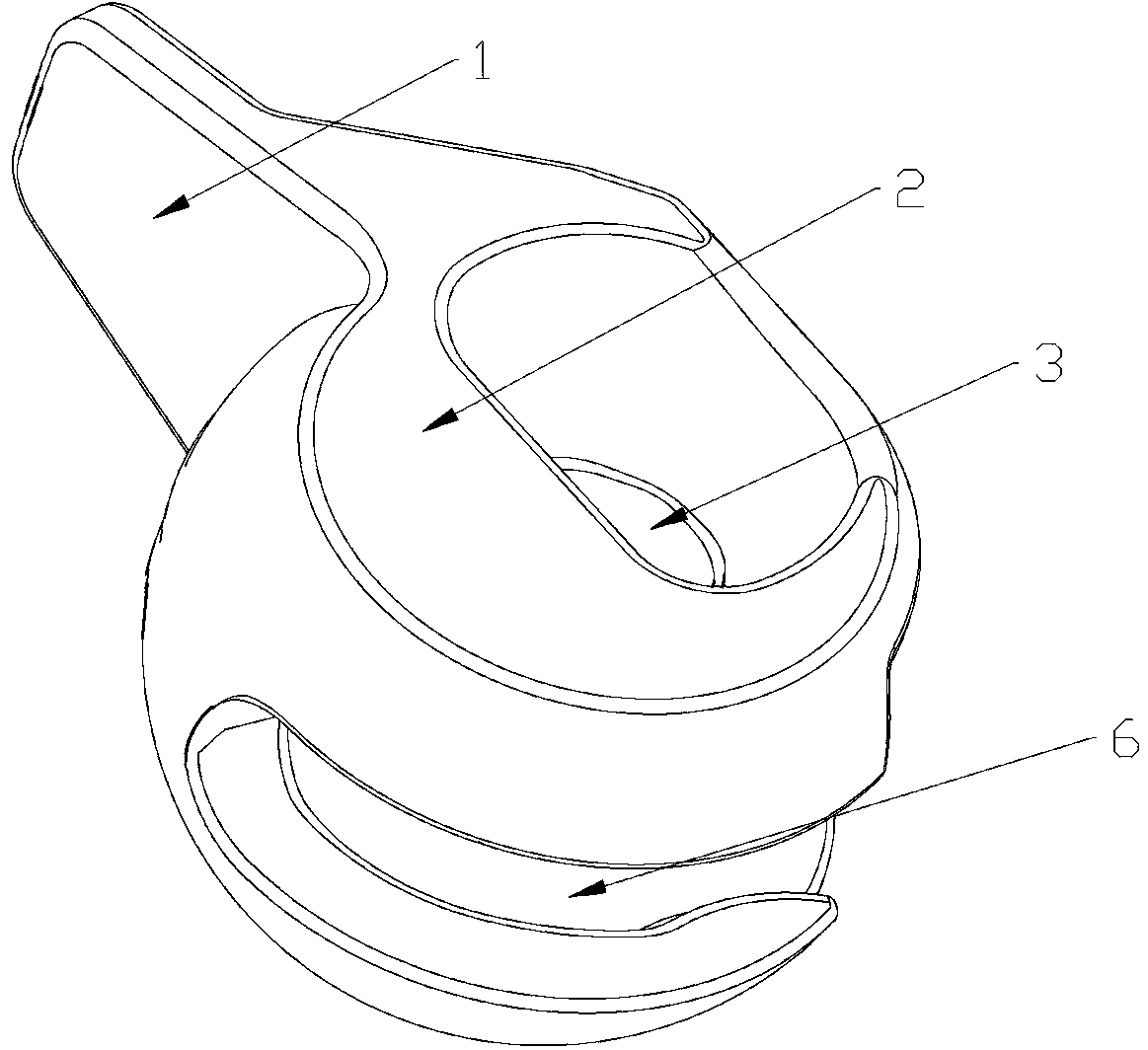

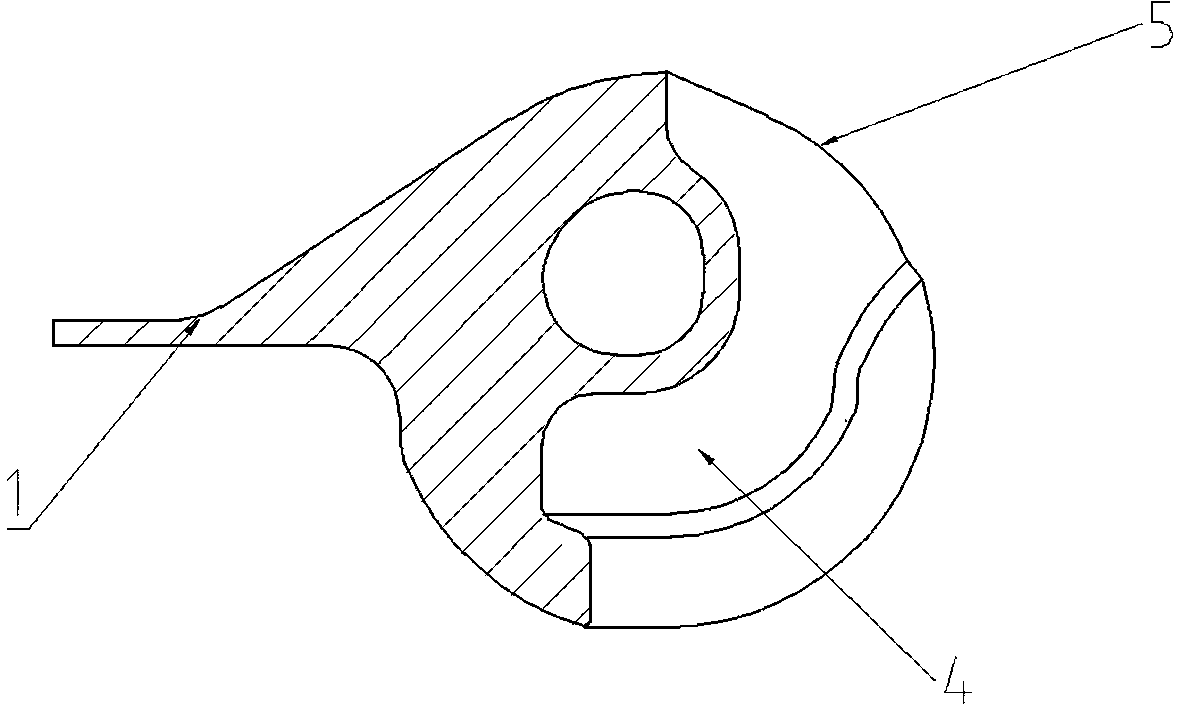

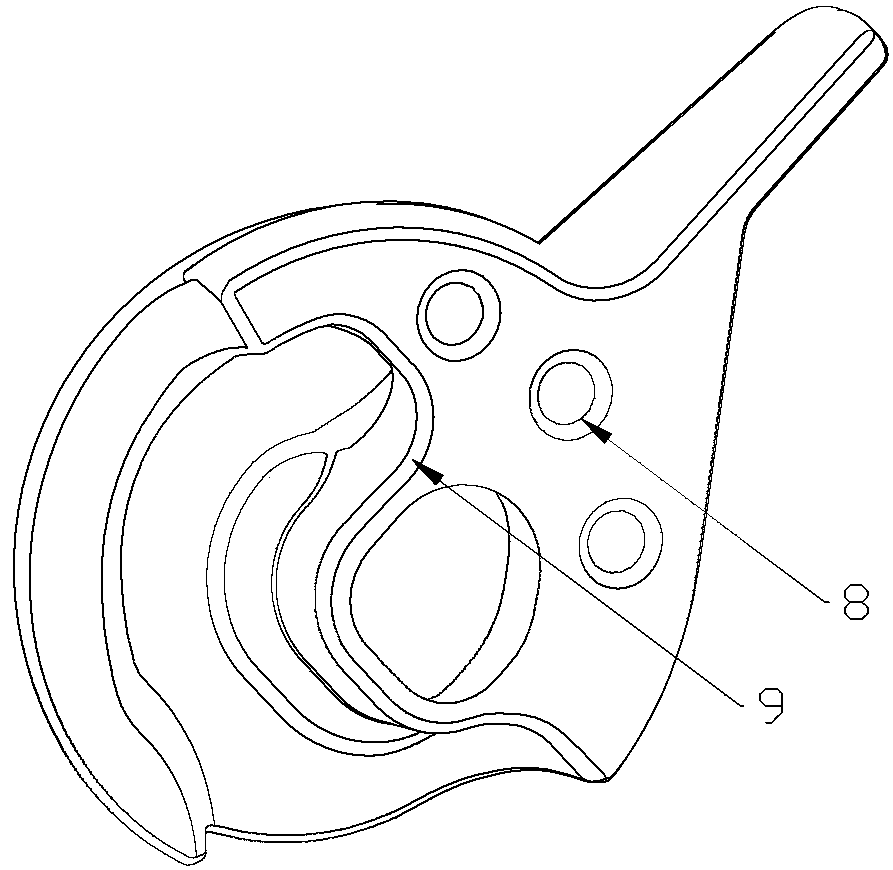

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, the following in conjunction with the attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 6 And the specific embodiment will further illustrate the present invention.

[0040] as attached figure 1 And attached figure 2 As shown, a hoisting sling includes a block 1 and a hoisting part 2, the hoisting part 2 is arranged in an oval structure, which is convenient to be placed in a semicircular pin groove, and the middle part of the hoisting part 2 is provided with a hoisting through hole 3. It is used to install the hook. The lower part of the hoisting part 2 is provided with a hoisting groove 4 for assembling the pin head. One side of the hoisting part 2 is provided with an assembly opening 5 .

[0041] Further, the blocking piece 1 and the lifting part 2 are provided as an integrated structure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com