Rubber sheet cooling device with mesh belt type sealing internal circulation

A cooling device and internal circulation technology, applied in the field of rubber machinery production, can solve problems such as unfavorable work of workshop workers, increased construction costs, low production efficiency, etc., to improve ambient temperature and workshop air quality, reduce initial investment costs, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the purpose, structure and function of the present invention, a mesh-belt-type closed internal circulation film cooling device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

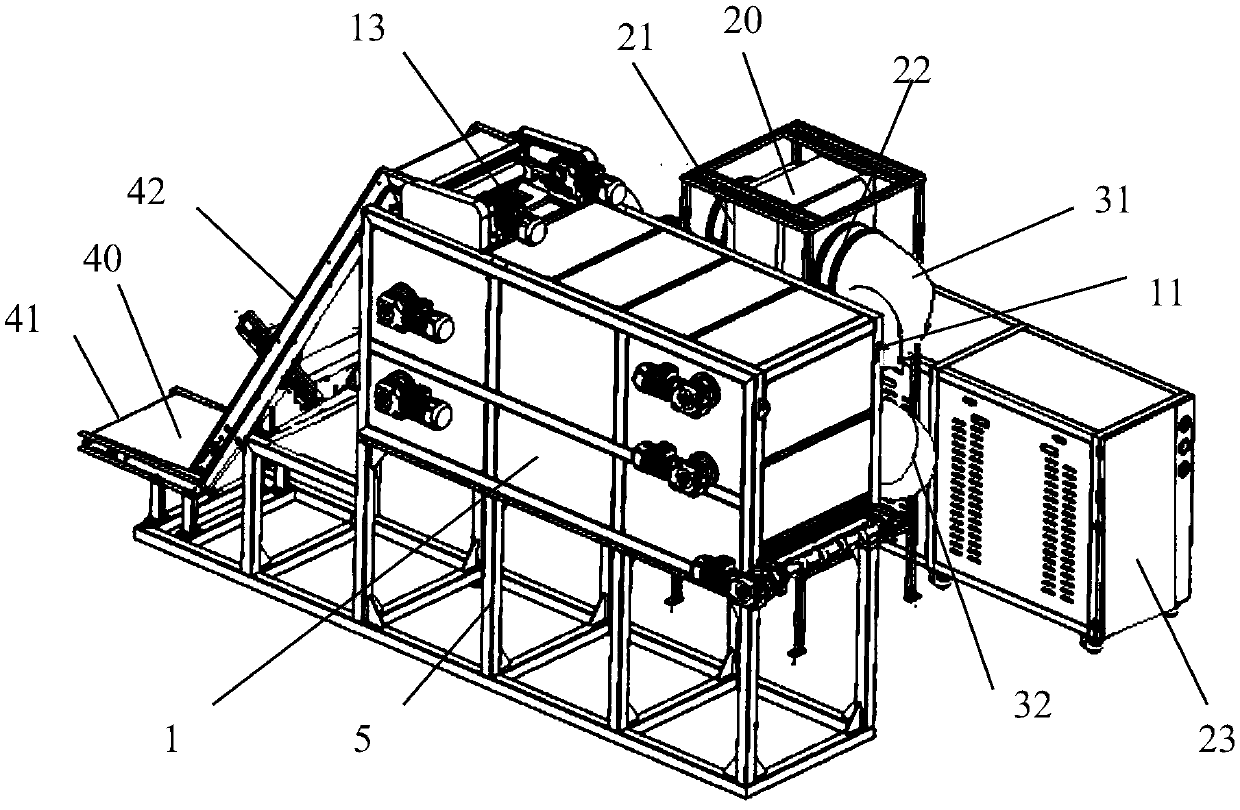

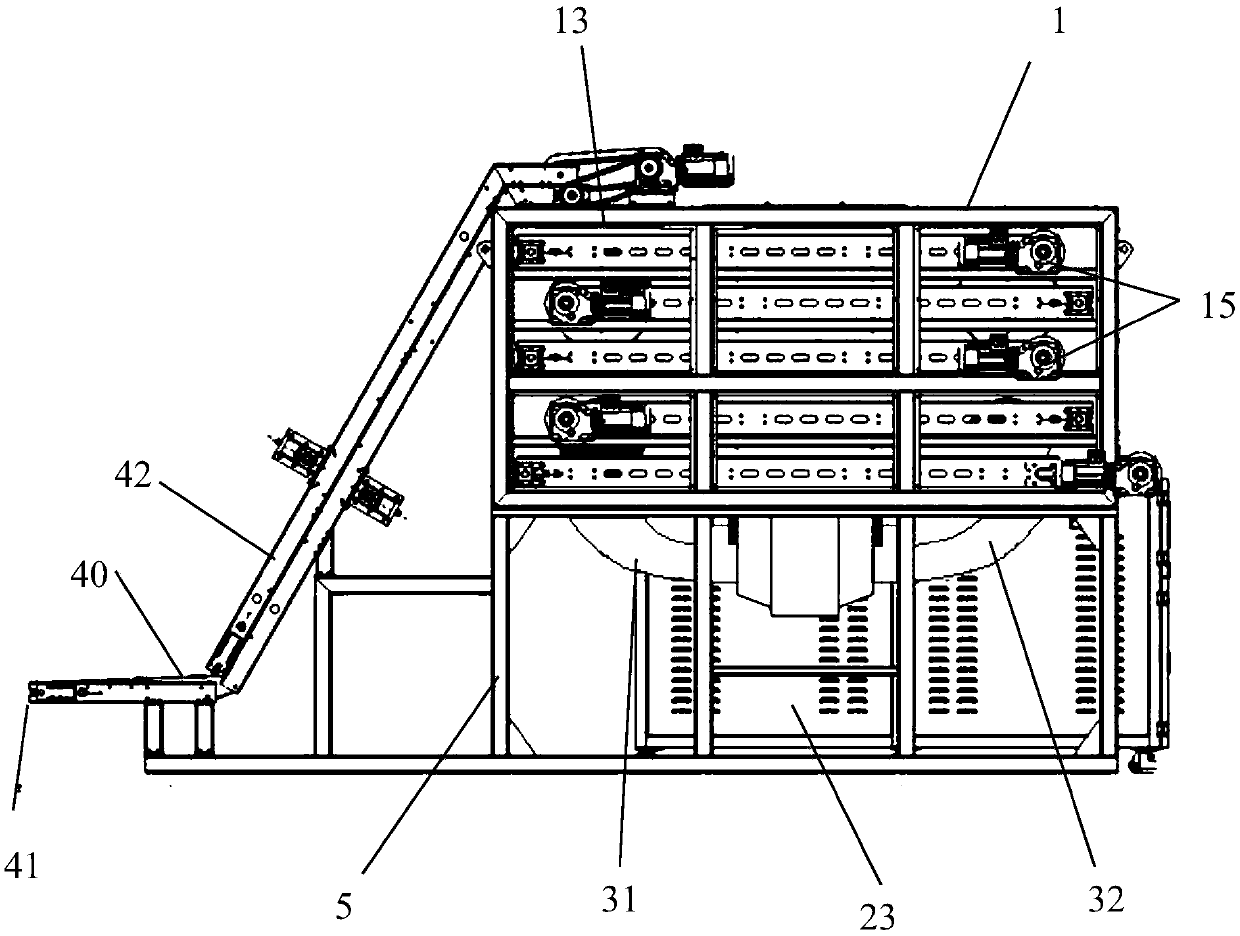

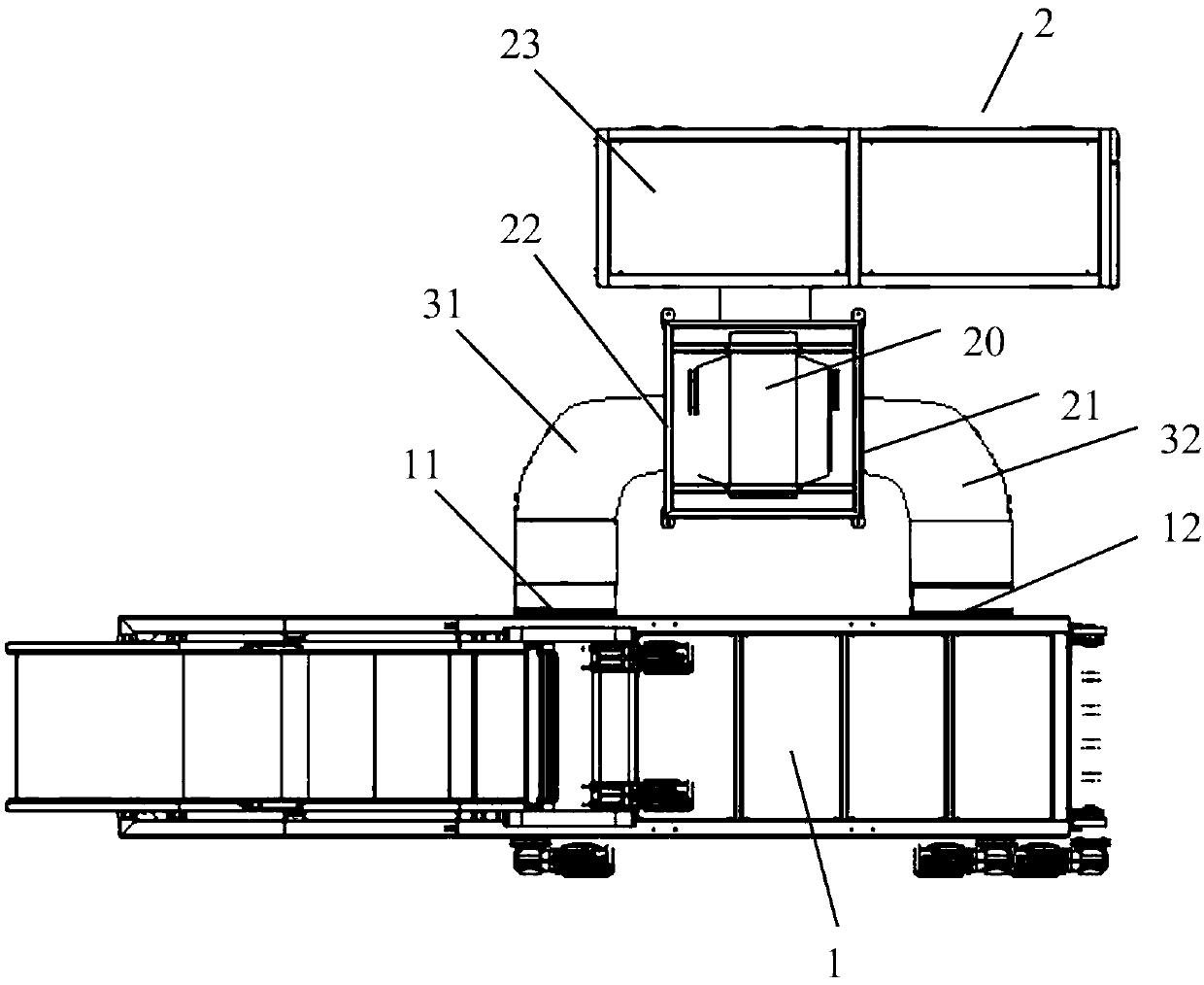

[0025] Such as Figure 1 to Figure 4 As shown, it is shown as a mesh belt type airtight internal circulation film cooling device of the present invention, which is used to cool the film, including a closed box 1, a refrigeration device 2 and a circulation system, the closed box 1 is a closed type, and the inside A mesh belt conveyor 15 for transporting films is provided, and the conveyor belts of the mesh belt conveyor 15 are stacked from top to bottom; the refrigeration device 2 includes a connected fan 20 and a host 21, and the host 23 is used for producing cold air and exchanging The heated hot air is reprocessed, and the fan 20 is used to blow and suck air to the closed box 1; the circulation syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com