A 3D printing pen that is convenient for porous discharge

A 3D printing and printing pen technology, applied to coating devices, 3D object support structures, manufacturing tools, etc., can solve problems such as inability to ensure color purity, uncontrollable dosage, and printing pen residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

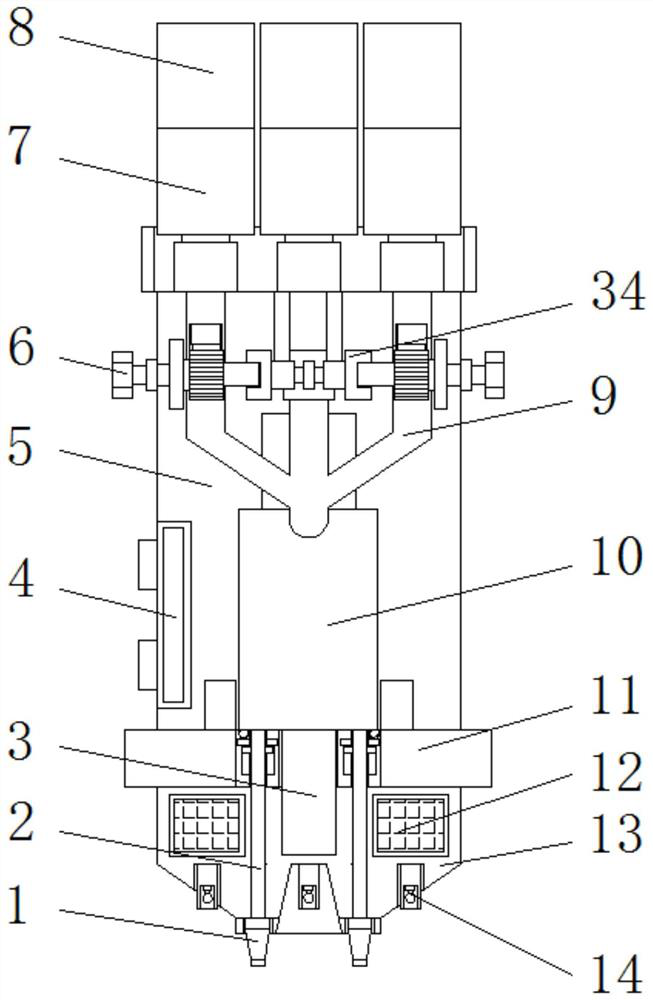

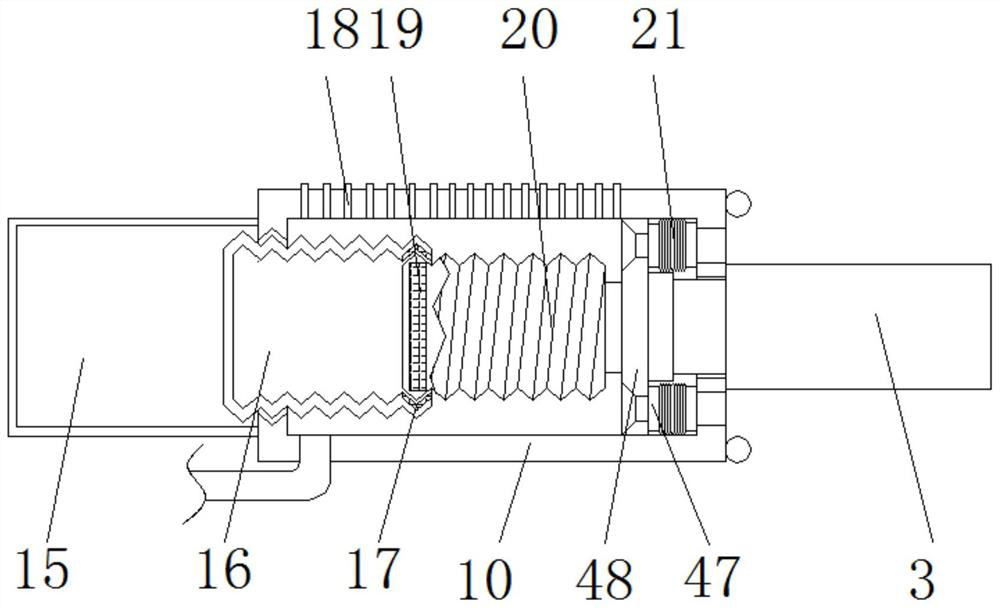

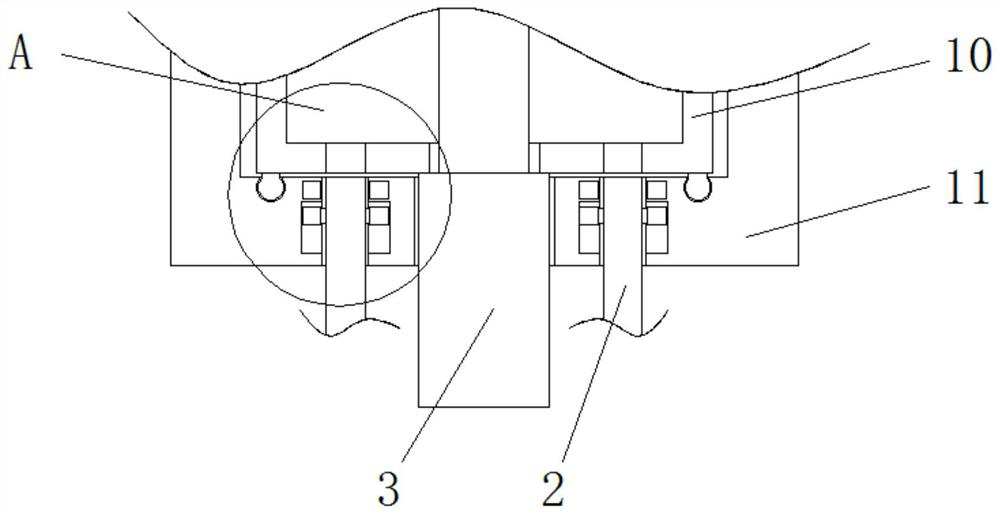

[0032] see Figure 1-10 , an embodiment 1 provided by the present invention: a 3D printing pen that is convenient for porous discharge, including a printing pen body 5, a feeding tube 9, a mixing tube 10 and a connecting seat 13, and the inside of the printing pen body 5 is provided with The feeding pipe 9 that is a four-way pipe, and the three ends of the feeding pipe 9 all extend to the top of the printing pen body 5, and the tops of the printing pen body 5 at the positions of the three ends of the feeding pipe 9 all extend to the top of the printing pen body 5. The liquid material tank 7 is connected, and the top inside the feed pipe 9 is provided with an internal thread, and one end of the liquid material tank 7 is provided with an external thread that cooperates with the internal thread of the feed pipe 9, and the top of the liquid material tank 7 is inserted into the There is an electric extrusion cylinder 8, and the end of the feed pipe 9 away from the liquid material t...

Embodiment 2

[0033] see Figure 11-12 , an embodiment 2 provided by the present invention: the mixing cylinder 10 is provided with three through holes 22, and there are three connecting holes 25 and plugs 33 corresponding to the through holes 22 on the rotating block 11, which are the same as the embodiment 1. The difference is that in Embodiment 1, there are two through holes 22, connecting holes 25 and plugs 33, so as to facilitate feeding through two nibs at the same time, while in Embodiment 2, through holes 22, connecting holes 25 and plug 33 intermediaries are set to three, are convenient to carry out feeding by three nibs, improve working efficiency.

[0034]Working principle: First, connect the liquid material tank 7 with the three primary colors to the feed pipe 9 through the cooperation of threads, so that the three different colors of red, yellow and blue are respectively formed into a four-way feed pipe. 9 inside the three pipes at the top, and then extrude the photosensitive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com