Storage and transfer device for double-groove knife boards of excavator

A transfer device and bevel knife technology, applied in the direction of transportation and packaging, packaging, rigid containers, etc., can solve the problems of increasing the difficulty of transfer, heavy weight, slipping of the main knife plate, etc., and achieve the effect of easy transfer and management, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

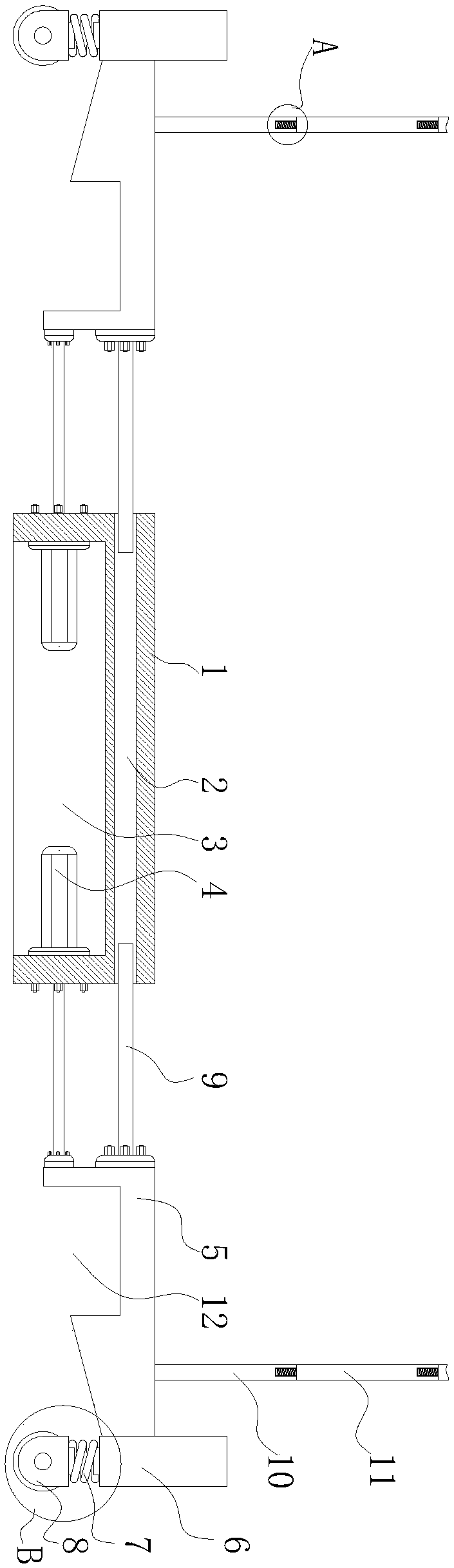

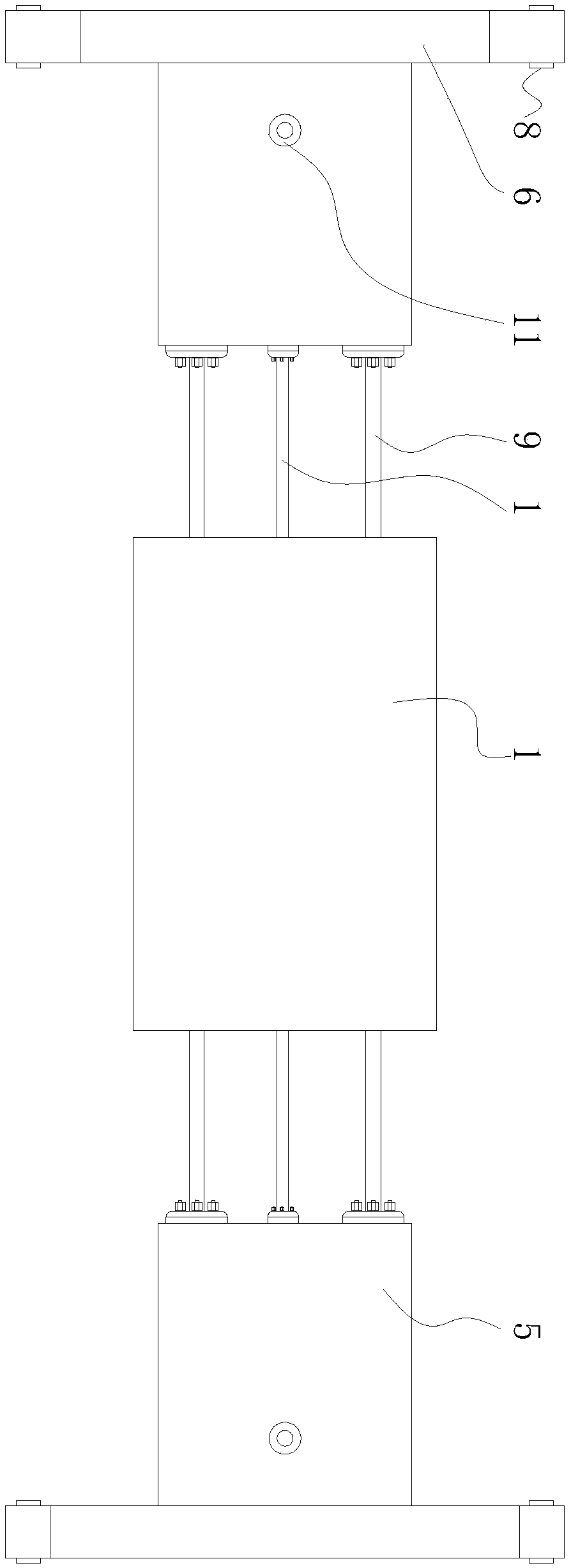

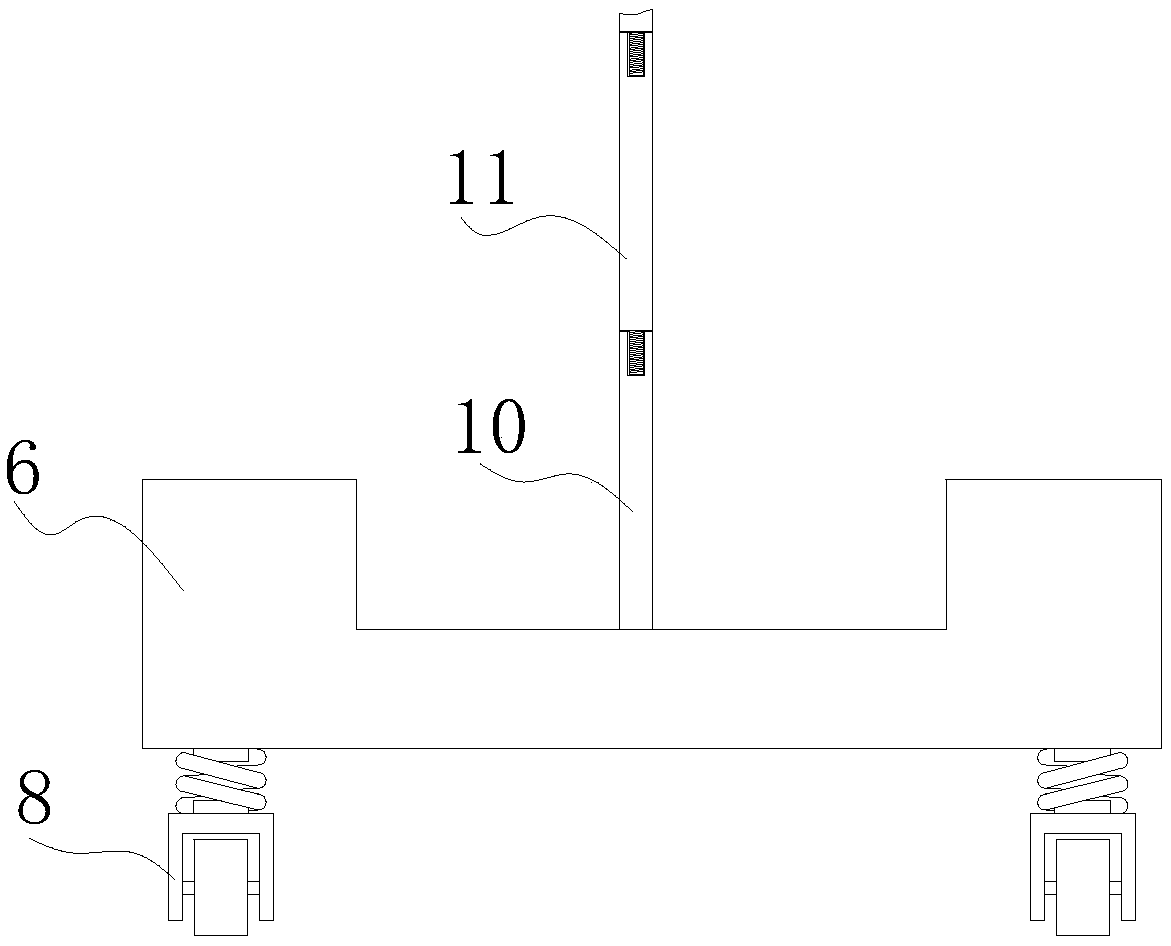

[0022] Such as Figure 1 to Figure 6 As shown, an excavator double-groove knife plate storage and transfer device is composed of a support base 1 and adjustable brackets mirrored on both sides of the support base 1. The left and right sides of the support base 1 are provided with through The guide hole 2, the lower end surface of the support seat 1 is provided with an assembly cavity 3, and two mirrored linear drive assemblies 4 are installed in the assembly cavity 3, and the driving end of the linear drive assembly 4 runs through the side wall of the assembly cavity 3, And extend to the side end of support seat 1, described bracket is made up of U-shaped pallet 6, moving roller 8 and guide bar 9 thereof, and movable roller 8 is installed on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com