Baking type waterborne acrylic coating composition with excellent thixotropy and preparation method thereof

A water-based acrylic and composition technology, applied in the direction of coating, etc., can solve the problems of decreased coating viscosity, coating sag, destroying the thixotropic effect of polyurethane thickeners, etc., to achieve the effect of improving strength and increasing system viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

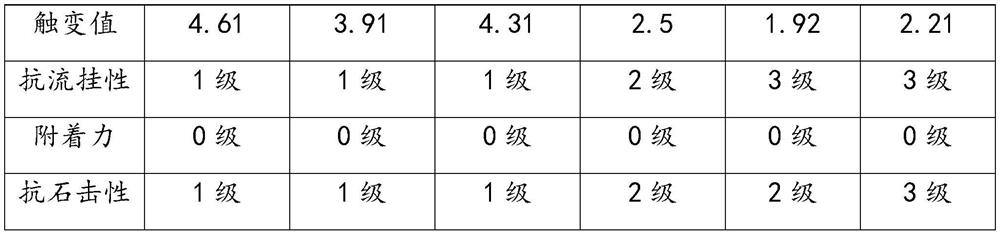

Embodiment 1

[0042] The baking-type water-based acrylic coating composition with excellent thixotropy of the present embodiment is mainly made of the following raw materials: functional filler A 0.2g DY CE, 12g deionized water, 35g hydroxyl-functionalized water-based resin containing tertiary amino groups, 3.2g water-based amino resin Resimene 717, 5g cosolvent A ethylene glycol butyl ether, 0.2g dispersant EDAPLAN 490, 0.2g leveling Agent BYK-348, 0.1g defoamer BYK-025, 0.1g pH regulator N,N-dimethylethanolamine, 9g titanium dioxide R902+, 2g pu carbon black, 28.6g precipitated barium sulfate, 0.4g rheology additive BYK-420, 4g co-solvent B ethylene glycol butyl ether.

[0043] The preparation method of the baking type waterborne acrylic paint composition with excellent thixotropy of the present embodiment may further comprise the steps:

[0044] 1) Preparation of functional filler pre-gel liquid GEL-1:

[0045] Add 12 grams of deionized water into the reaction bottle, start the stirri...

Embodiment 2

[0054] The baking type water-based acrylic coating composition with excellent thixotropy of this embodiment is mainly made of the following raw materials: 0.05g functional filler A LT, 10g deionized water, 30g hydroxyl-functionalized water-based resin containing tertiary amino groups, 4.5g water-based amino resin CYMEL 325, 1.5g co-solvent A ethylene glycol butyl ether, 3g co-solvent A propylene glycol methyl ether, 0.8g dispersion Agent DISPERBYK-190, 0.1g leveling agent BYK-348, 0.65g defoamer Foamex 810, 0.05g pH regulator triethylamine, 4g titanium dioxide R 902+, 1g pu carbon black, 40g precipitated barium sulfate, 0.85g rheological additive BYK-D 420, 3.5g cosolvent B butyl glycol ether .

[0055] The preparation method of the baking type waterborne acrylic paint composition with excellent thixotropy of the present embodiment may further comprise the steps:

[0056] 1) Preparation of functional filler pre-gel liquid GEL-2:

[0057] Add 10 grams of deionized water in...

Embodiment 3

[0066] The baking-type waterborne acrylic coating composition with excellent thixotropy of this embodiment is mainly made of the following raw materials: 0.45g functional filler A DY CE, 15g deionized water, 38g hydroxyl-functionalized water-based resin containing tertiary amino groups, 2.5g water-based amino resin Resimene 717, 5g co-solvent A ethylene glycol butyl ether, 3g co-solvent A propylene glycol methyl ether, 0.1g dispersion Agent EDAPLAN 490, 0.55g leveling agent BYK-348, 0.2g defoamer BYK-025, 0.4g pH regulator N,N-dimethylethanolamine, 15g titanium dioxide R 902+, 10g calcium carbonate, 0.1g BYK -420, 9.7g co-solvent B ethylene glycol butyl ether.

[0067] The preparation method of the baking type waterborne acrylic paint composition with excellent thixotropy of the present embodiment may further comprise the steps:

[0068] 1) Preparation of functional filler pre-gel liquid GEL-3:

[0069] Add 15 grams of deionized water into the reaction bottle, start the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com