Prefabricated assembled bridge deck plate dry joint connection structure and implementation method

A prefabricated assembly and bridge deck technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as more stringent requirements and can not meet resistance at the same time, reduce workload, compensate for errors, and force mechanism clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the two methods of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] Method 1:

[0029] Implementation method of dry joint connection construction of prefabricated bridge deck:

[0030] Step 1: Prepare the precast concrete bridge deck (1) in the factory, the specific steps are as follows:

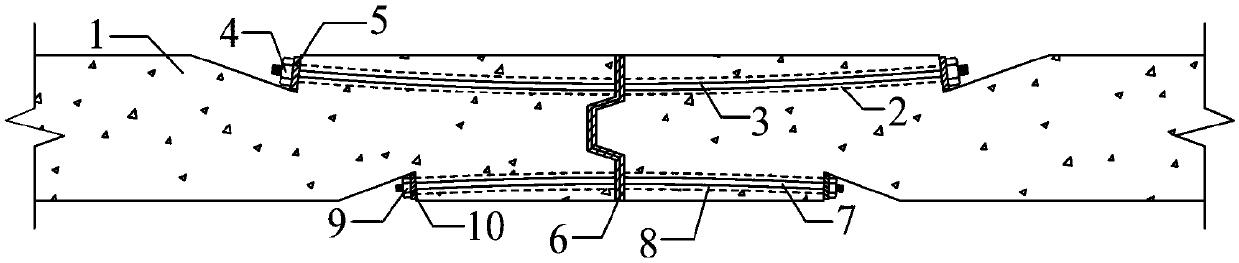

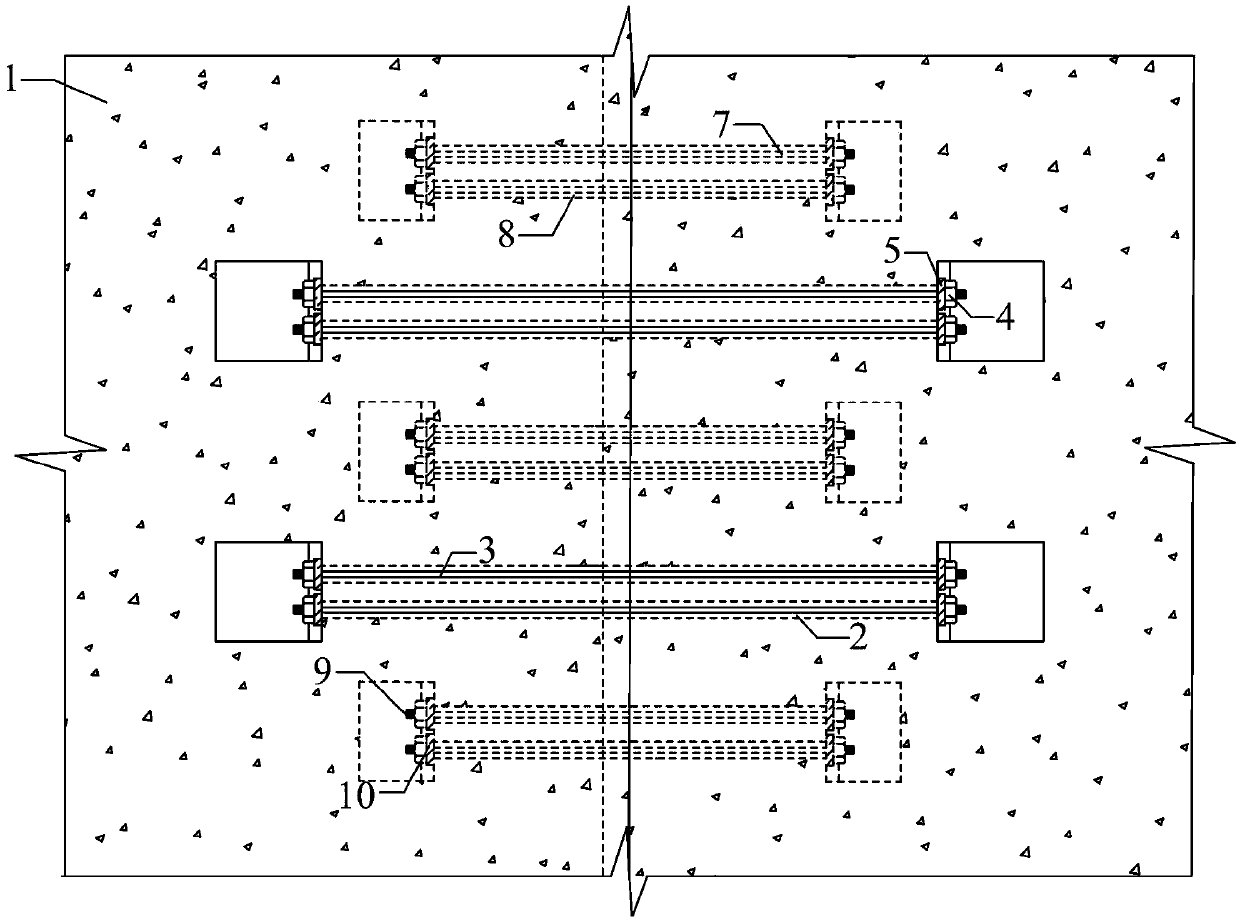

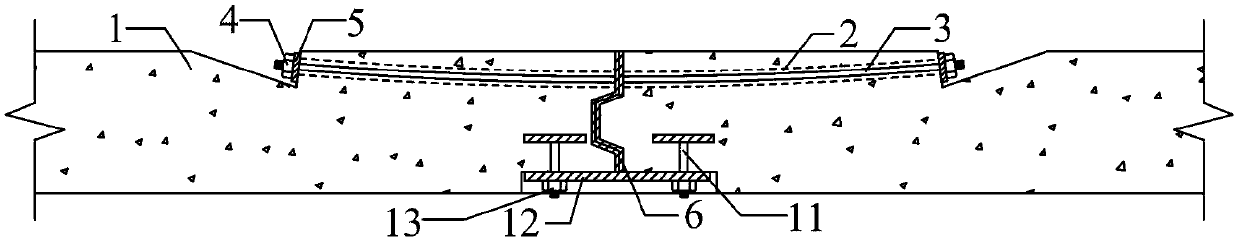

[0031] 1) Install the formwork of the precast concrete bridge deck (1), and the two ends of the formwork are designed in the form of concave-convex dry joints; the top and bottom of the bridge deck are respectively arranged with prestressed tunnels at the top (2) and reserved prestressed tunnels at the bottom (3).

[0032] 2) Bind the steel mesh of the bridge deck, and pour the precast concrete bridge deck (1) concrete.

[0033] 3) Water stop strips (6) are attached to both ends of the precast concrete bridge deck (1).

[0034] Step 2: Assembling the precast concrete bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com