Fabricated house with composite lightweight walls

A light-weight wall and prefabricated technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of weak clamping effect of components, heavy weight of pre-supported components, and scratches on the wall surface, so as to reduce the Difficult to make, high bearing capacity, firm fixation and beautiful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

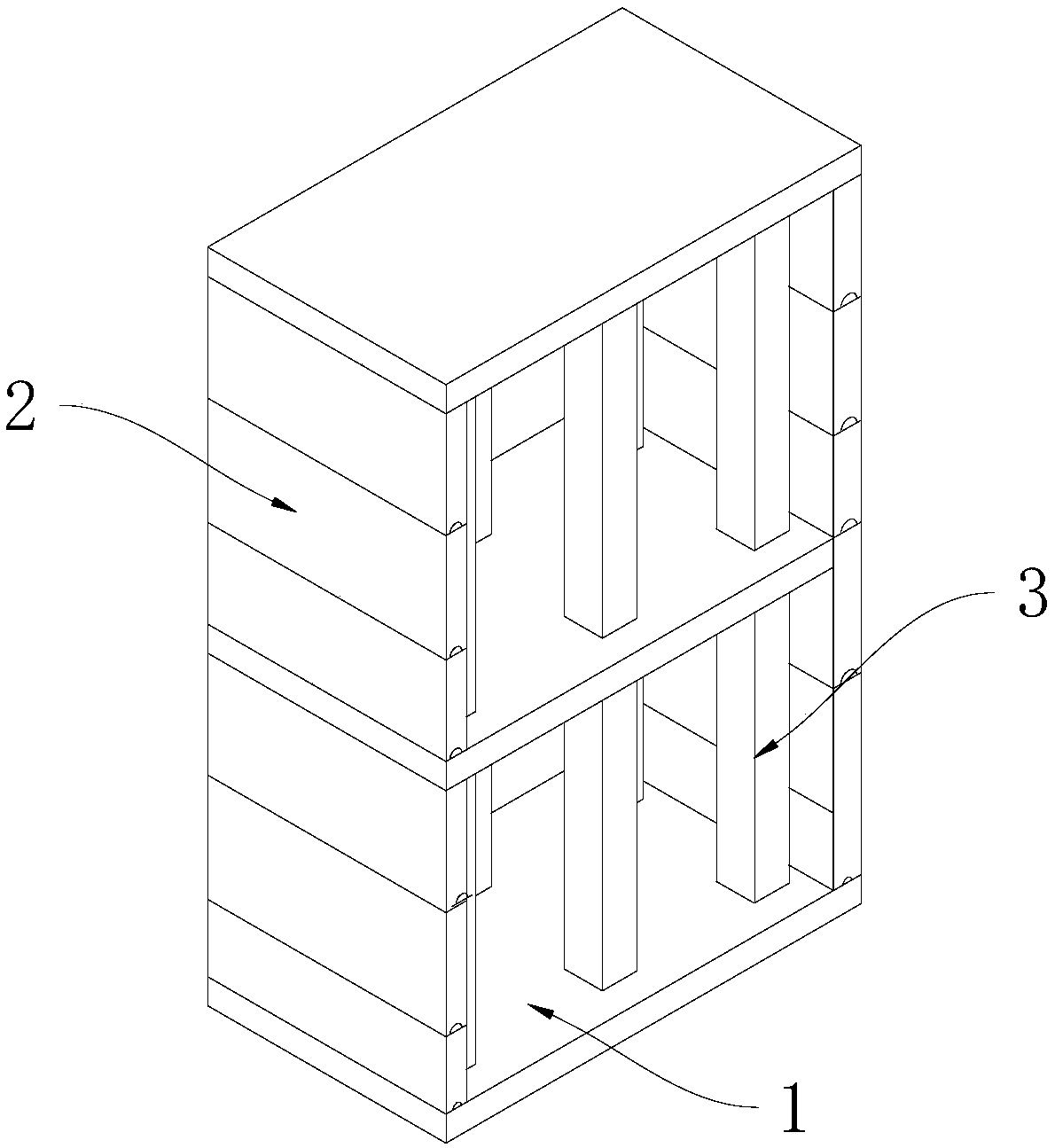

[0032] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, the present invention has a prefabricated house with composite lightweight walls, including several floor slabs 1, walls and support columns 3, and several support columns 3 are fixedly connected between two adjacent floor slabs 1 to form Several floors. The walls are detachably connected to the support columns, and a plurality of walls surround the support columns to form the outer walls of the house,

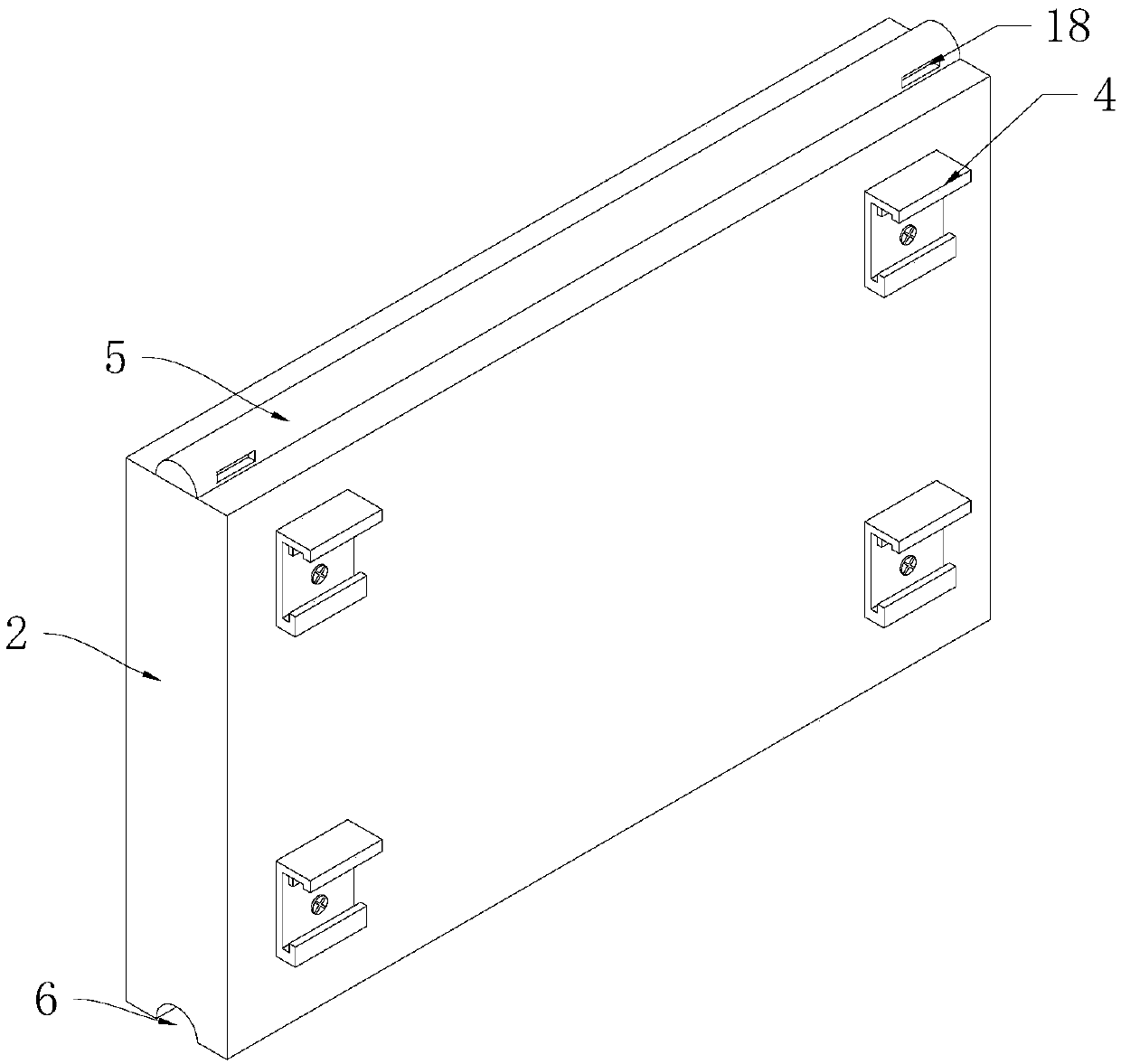

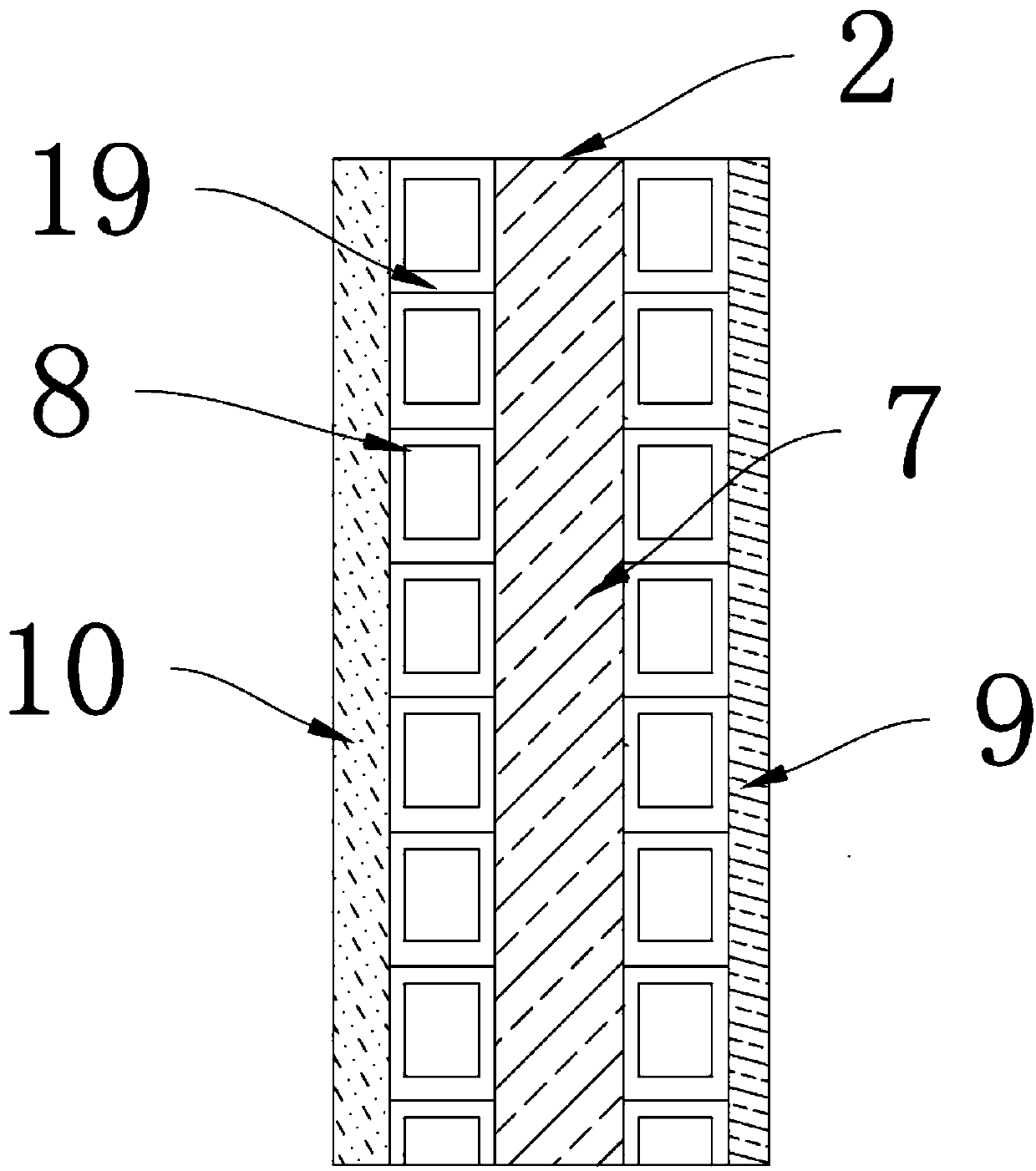

[0033] Wherein, the wall body is formed by splicing several wall panels 2 up and down. The support columns 3 are fixedly connected on both sides between two adjacent floor slabs 1, the middle part of the top of the wall panel 2 is fixedly connected with a connecting block 5, the middle part of the bottom end of the wall panel 2 is provided with a connecting groove 6, and the top of each floor 1 Both sides are provided with connecting blocks 5 matching the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com