3D printing wall with embedded enclosure structural column and processing method of 3D printing wall

A technology of 3D printing and processing method, applied in the direction of building structure, wall, column, etc., can solve the problems of affecting the overall beauty of the building, complicated column production, prolonging the construction period, etc., to shorten the construction period, make it convenient, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

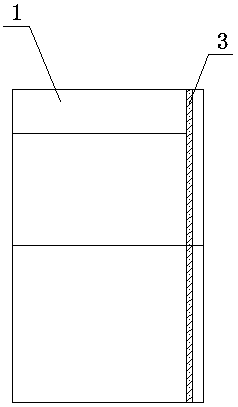

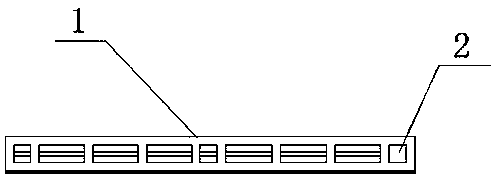

[0030] This embodiment provides a 3D printed wall with an embedded enclosure structure column, such as figure 1 , as shown in 2, includes a wall 1, the wall 1 is reserved inside the wall 1 to form an enclosure structure column cavity 2 during the printing process of the wall 1, and the cavity 2 is arranged along the height direction of the wall 1 , and the position of the cavity 2 is the load-bearing position of the wall 1 . A reinforced steel skeleton is laid in the cavity 2, and cement is poured to form an embedded enclosure structure 3 to form columns.

[0031] This embodiment also provides a processing method for a 3D printed wall 1 with an embedded enclosure construction column, comprising the following steps:

[0032] S1: Carry out the overall design according to the required building, determine the wall panel connection structure and the setting position of the enclosure structure column, and then compile the printing track of 3D printing;

[0033] S2: Transport the 3...

Embodiment 2

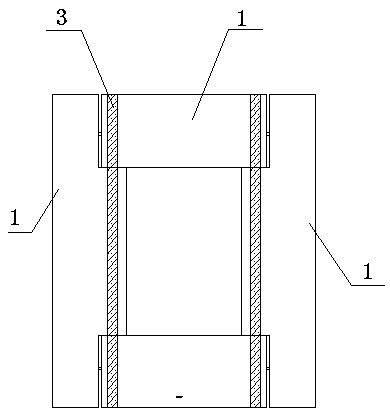

[0039] This embodiment provides a 3D printed wall with an embedded enclosure structure column, such as image 3 , as shown in 4, including a wall 1, the wall 1 is reserved inside the wall 1 to form an enclosure structure column cavity 2 during the printing process of the 3D printing equipment, and the cavity 2 is arranged along the height direction of the wall 1 , and the position of the cavity 2 is the load-bearing position of the wall 1 and the connection of adjacent walls 1 . A reinforced steel skeleton is laid in the cavity 2, and cement is poured to form an embedded enclosure structure 3 to form columns.

[0040] This embodiment also provides a processing method for a 3D printed wall 1 with an embedded enclosure construction column, comprising the following steps:

[0041] S1: Carry out the overall design according to the required building, determine the wall panel connection structure and the setting position of the enclosure structure column, and then compile the print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com