Continuously-variable transmission system for electrically driven vehicles

A technology of continuously variable speed and continuously variable speed mechanism, which is applied in the direction of transmission, transmission parts, transmission control, etc., and can solve the problem that the power and power consumption performance of pure electric vehicles cannot be brought to the maximum level, and the motor efficiency and torque cannot be achieved. Make full use of and affect the vehicle's driving comfort and other issues, and achieve the effect of improving low-speed dynamics and climbing performance, improving energy consumption utilization, and improving vibration and noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

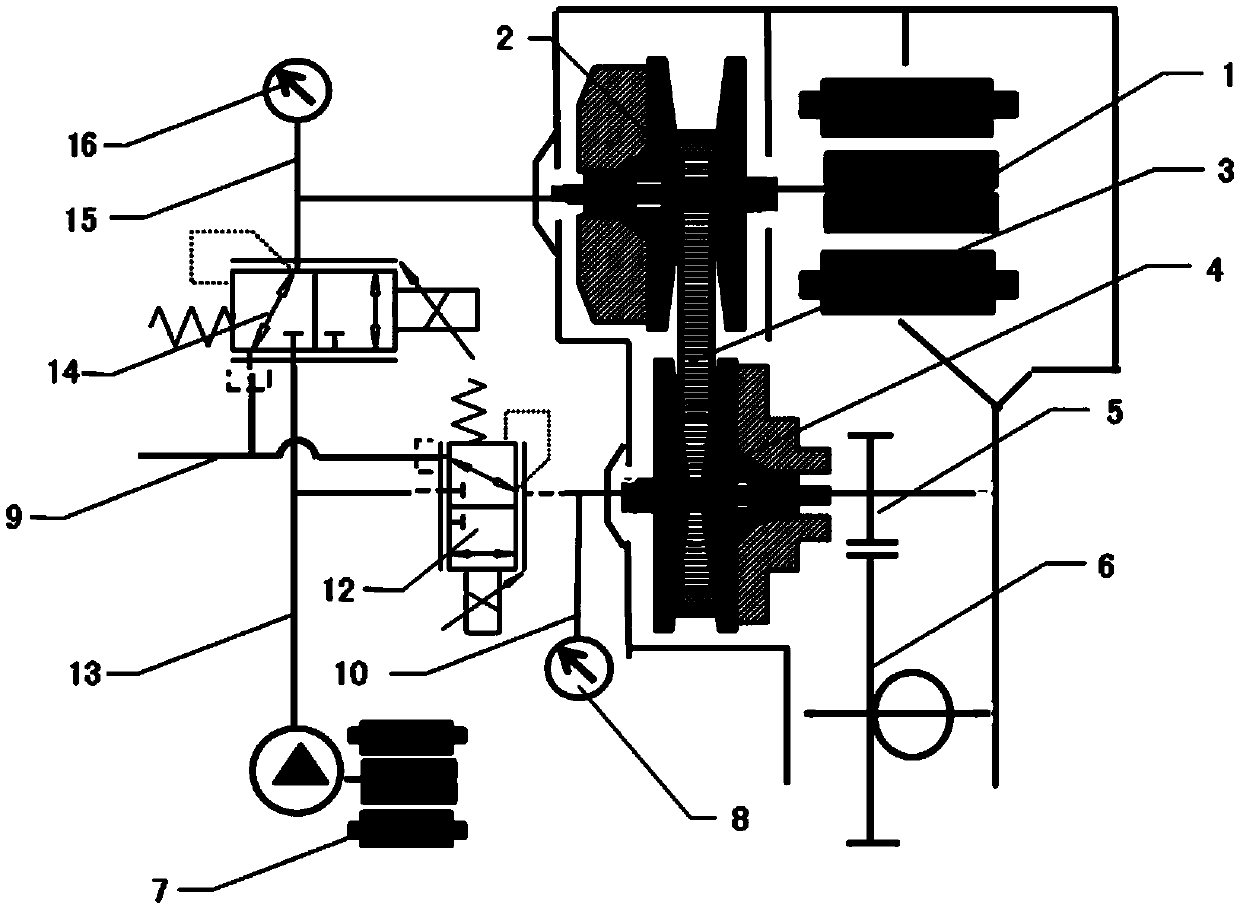

Embodiment 1

[0027] like figure 1 As shown, this embodiment provides a continuously variable transmission system for an electric drive vehicle, including a continuously variable transmission mechanism and a hydraulic actuator system for adjusting the transmission ratio of the continuously variable transmission mechanism. The continuously variable transmission mechanism includes a driving pulley 2, a driven pulley 4, and an endless transmission belt 3 arranged on the driving pulley 2 and the driven pulley 4; the hydraulic actuator system includes an oil pump 7 for guiding hydraulic oil to The first pressure oil passage for driving the pulley 2 and adjusting the width of the pulley groove of the driving pulley 2 and for guiding the hydraulic oil to the driven pulley 4 and for adjusting the pulley groove of the driven pulley 4 The second pressure oil circuit with a wide groove; the first pressure oil circuit and the second pressure oil circuit are connected to the oil pump 7, and the first pr...

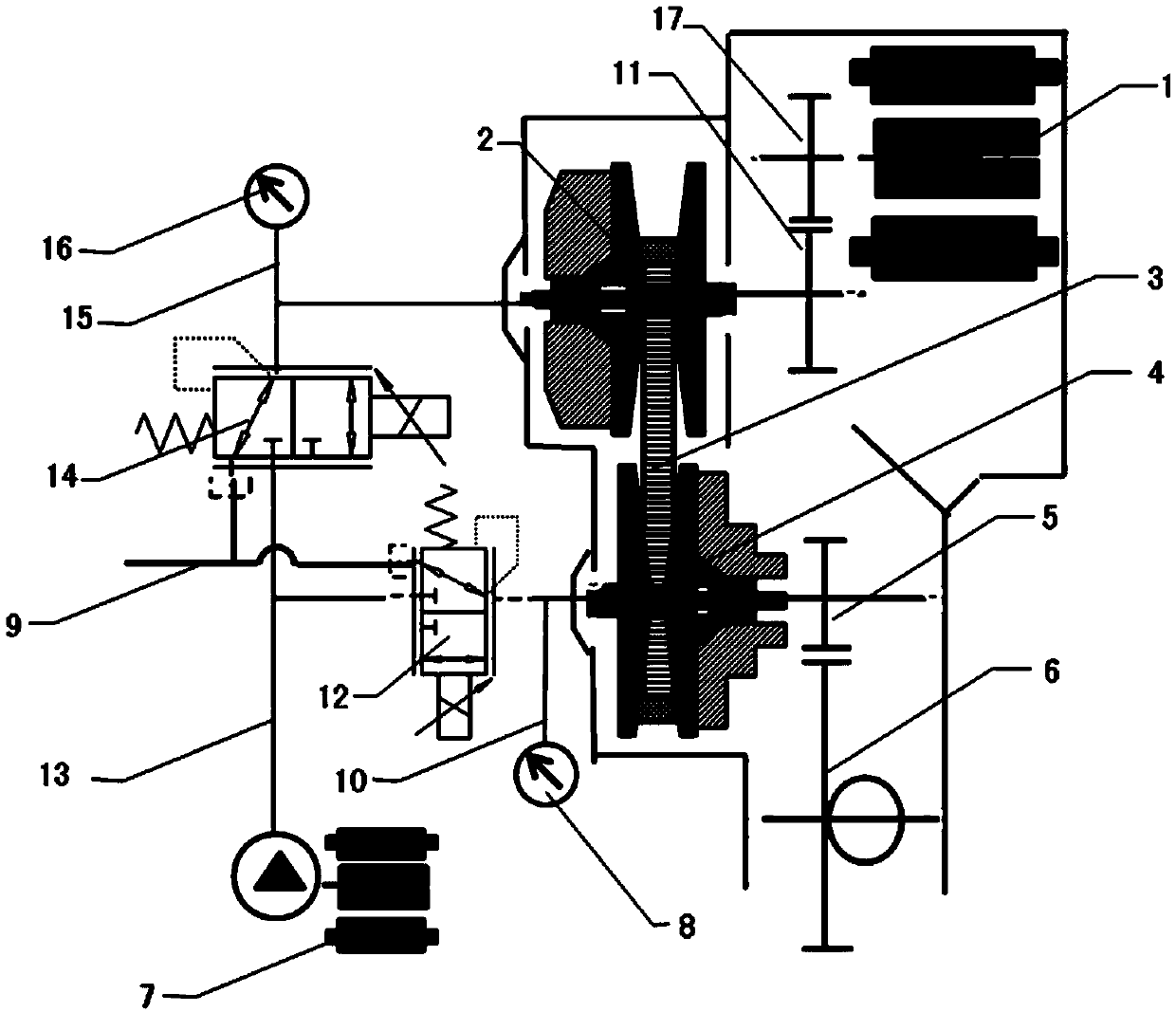

Embodiment 2

[0036] like figure 2 As shown, this embodiment provides a continuously variable transmission system for an electric drive vehicle, including a continuously variable transmission mechanism, a power transmission mechanism and a hydraulic actuator system for adjusting the transmission ratio of the continuously variable transmission mechanism. The continuously variable transmission mechanism includes a driving pulley 2, a driven pulley 4, and an endless transmission belt 3 arranged on the driving pulley 2 and the driven pulley 4; the hydraulic actuator system includes an oil pump 7 for guiding hydraulic oil to The first pressure oil passage for driving the pulley 2 and adjusting the width of the pulley groove of the driving pulley 2 and for guiding the hydraulic oil to the driven pulley 4 and for adjusting the pulley groove of the driven pulley 4 The second pressure oil circuit with a wide groove; the first pressure oil circuit and the second pressure oil circuit are connected to...

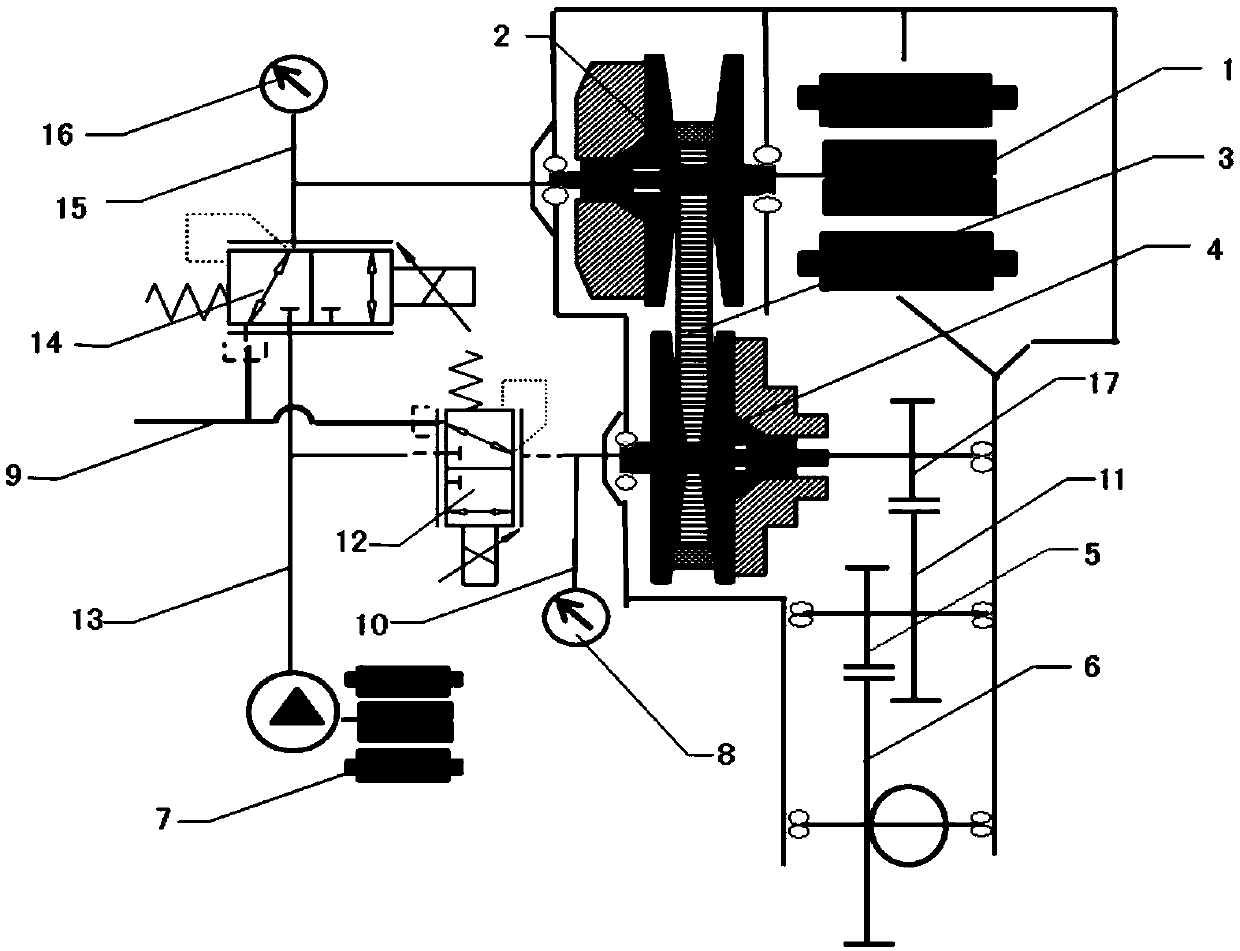

Embodiment 3

[0047] like image 3 As shown, this embodiment provides a continuously variable transmission system for an electric drive vehicle, including a continuously variable transmission mechanism, a power transmission mechanism and a hydraulic actuator system for adjusting the transmission ratio of the continuously variable transmission mechanism. The continuously variable transmission mechanism includes a driving pulley 2, a driven pulley 4, and an endless transmission belt 3 arranged on the driving pulley 2 and the driven pulley 4; the hydraulic actuator system includes an oil pump 7 for guiding hydraulic oil to The first pressure oil passage for driving the pulley 2 and for adjusting the width of the pulley groove of the driving pulley 2 and for guiding the hydraulic oil to the driven pulley 4 and for adjusting the pulley groove of the driven pulley 4 The second pressure oil circuit with a wide groove; the first pressure oil circuit and the second pressure oil circuit are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com