Lamp demisting device, lamp, vehicle and lamp demisting method

A technology for defogging devices and lamps, which can be applied to road vehicles, signal devices, vehicle parts, etc., and can solve the problems of desiccant moisture absorption capacity decline, disappearance, streaks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

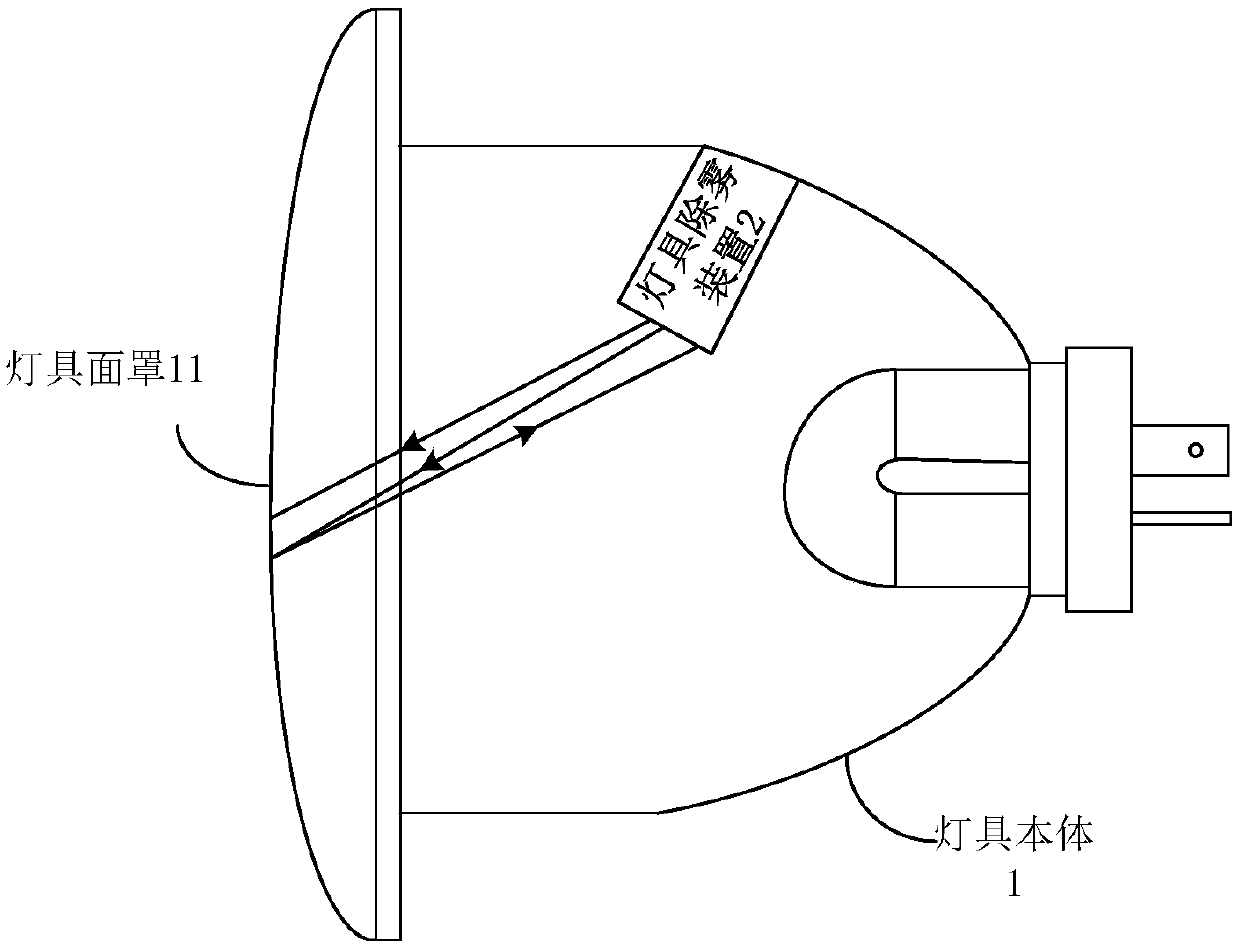

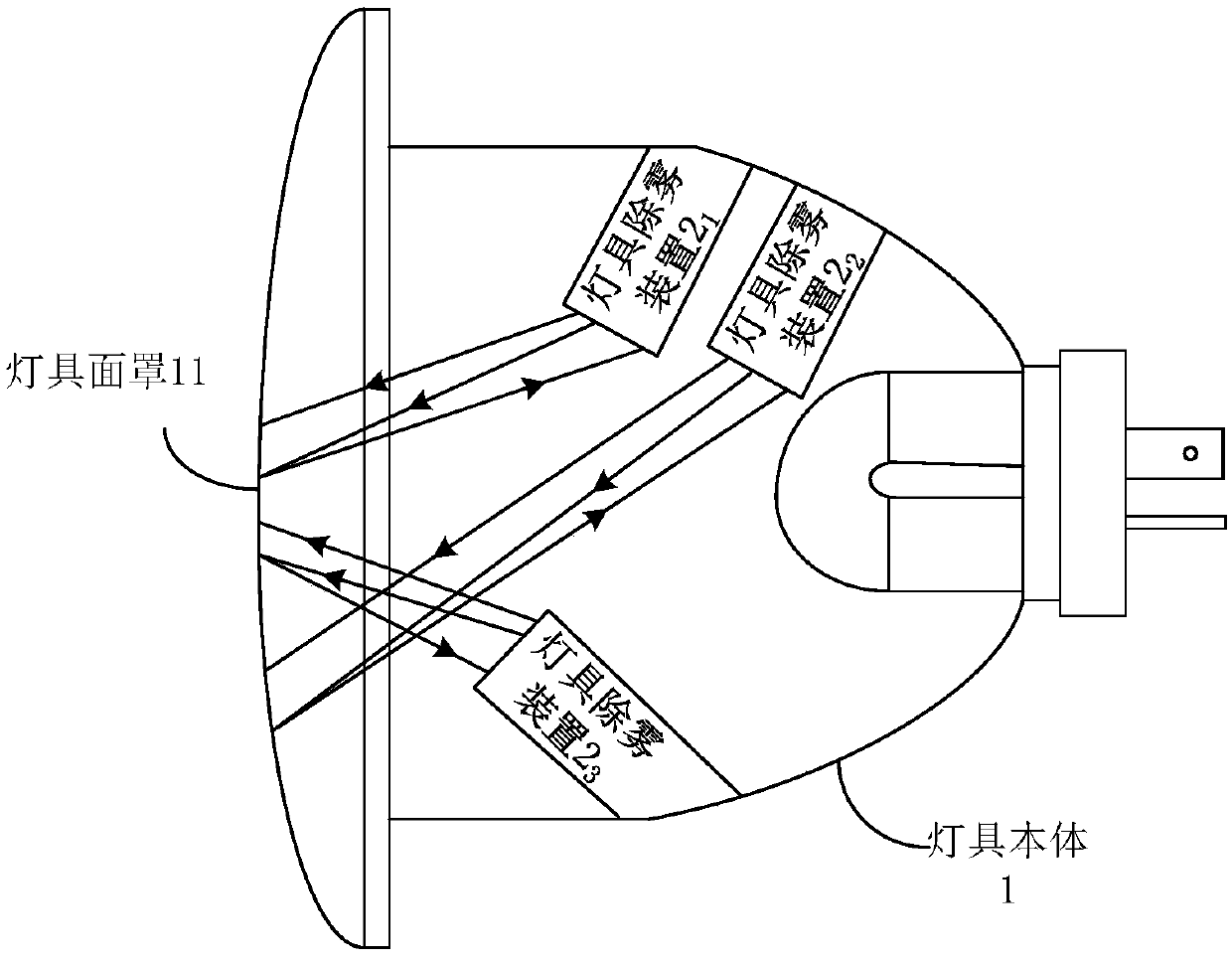

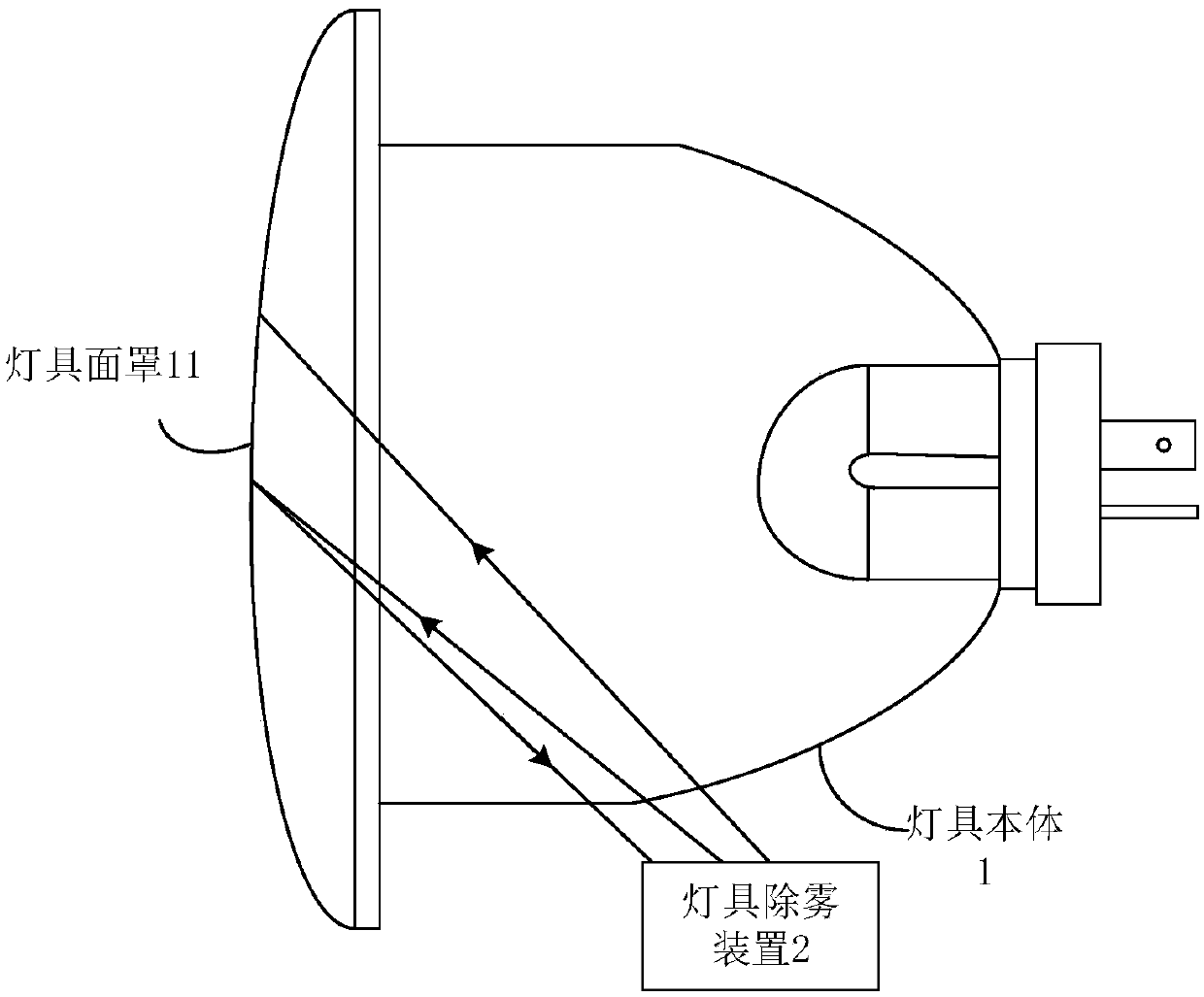

[0044] The present disclosure provides a lamp, such as Figure 1A to Figure 1D As shown, the lamp may include a lamp body 1 and at least one lamp defogging device 2 , wherein the lamp body 1 may include a lamp face cover 11 .

[0045] In the present disclosure, the lamp can be, for example, a car lamp, a street lamp, a bathroom lighting lamp, etc., and the lamp can include a lamp defogging device 2 (such as Figure 1A , 1C shown), may also include multiple lamp defogging devices 2 (such as Figure 1B , 1D shown), and the above-mentioned at least one lamp defogging device 2 can be arranged in the lamp body 1 (such as Figure 1A , 1B shown), it can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com