Double-plunger rotary oil well pump

An oil pump and double plunger technology is applied in the field of double plunger self-rotating oil pump to achieve the effects of reducing accumulation, lowering operating costs and preventing sand sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

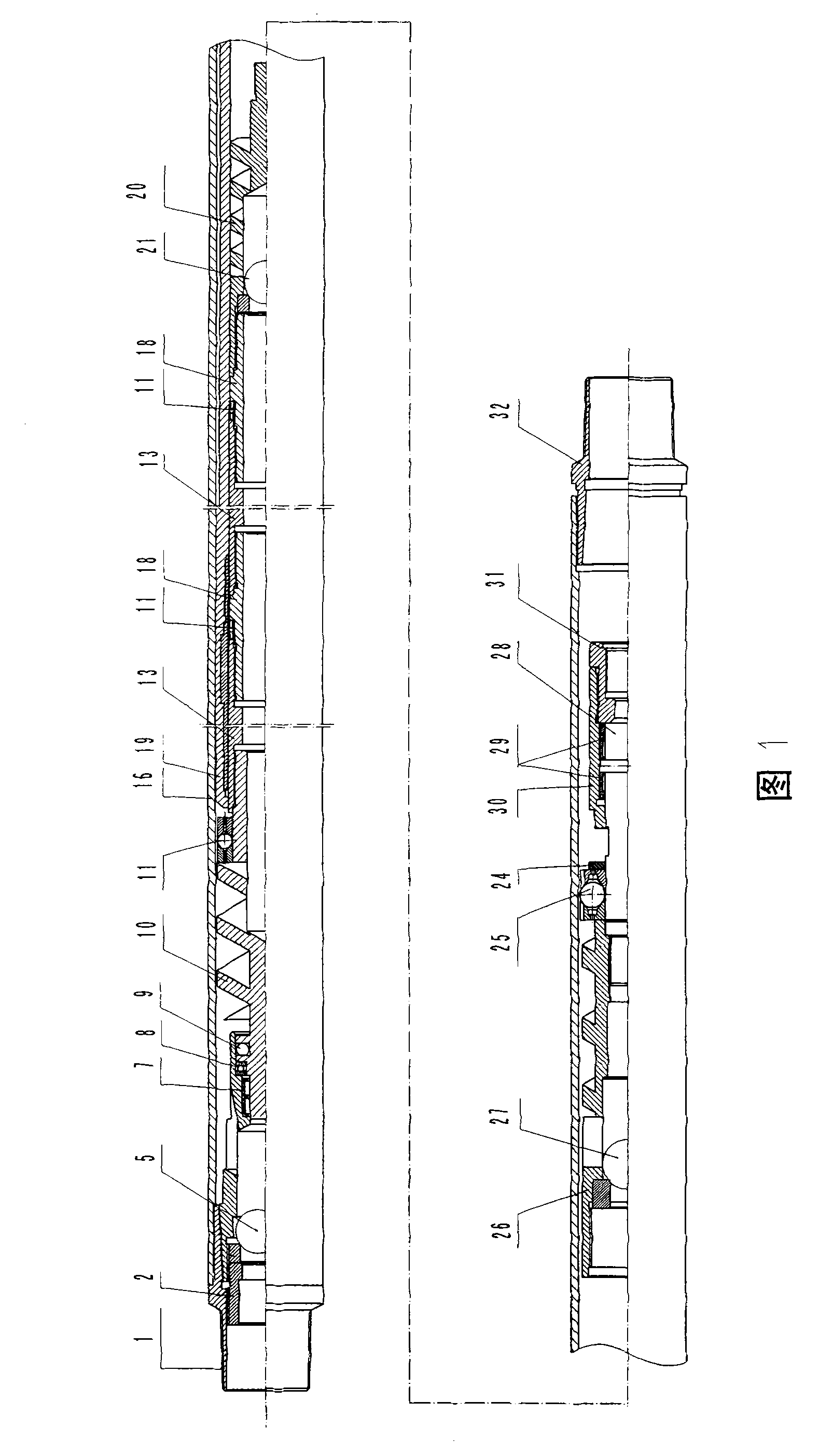

[0029] Such as figure 1 As shown, the double plunger self-rotating oil well pump of the present invention is made of the plunger (13, 18) of the center layer and the two-layer pump barrel (outer pump barrel 16 and main pump barrel 19) of the outer layer, and the main pump barrel is equivalent to the outer pump barrel. The plunger in the barrel, so the present invention is called double plunger.

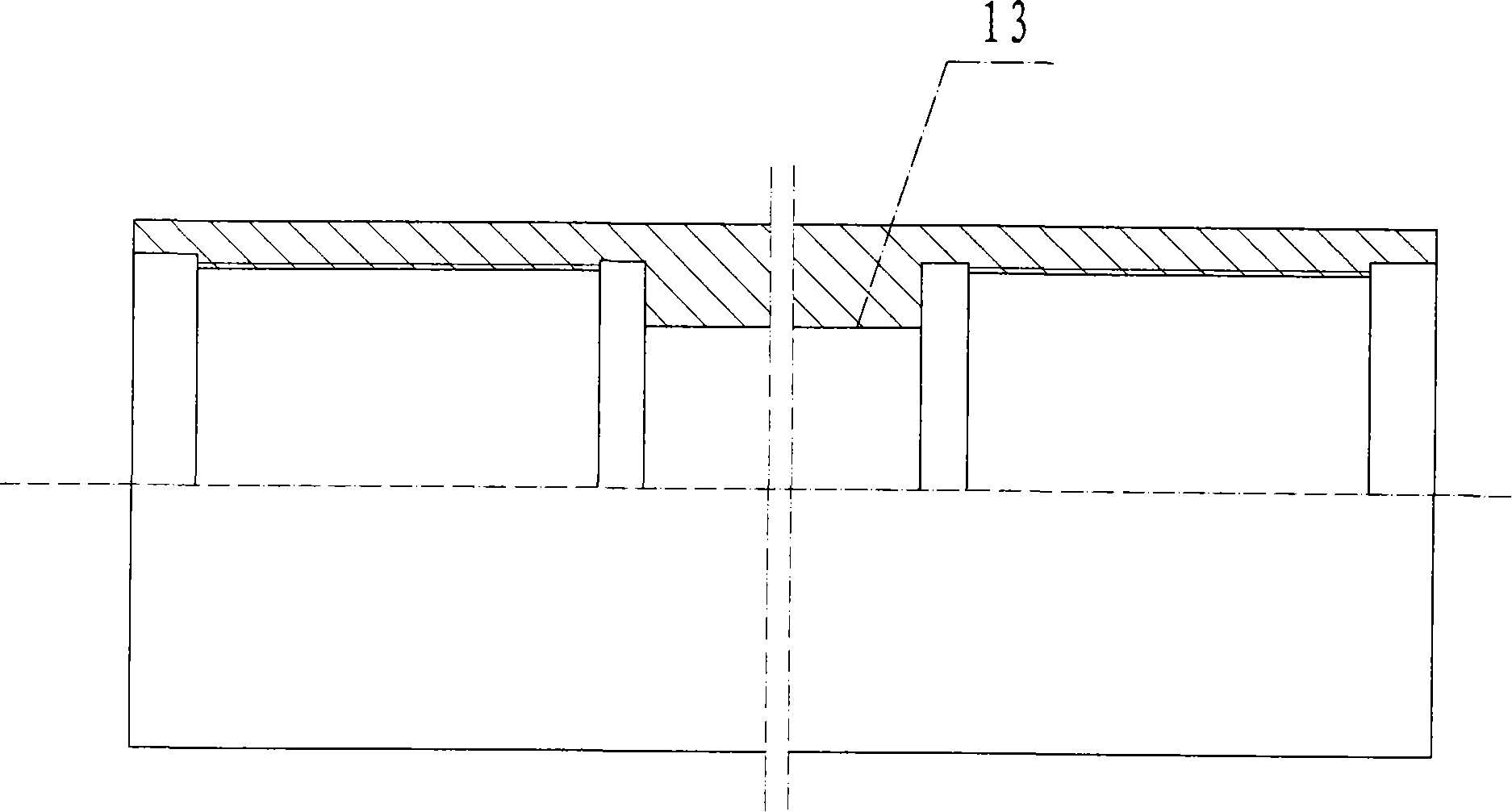

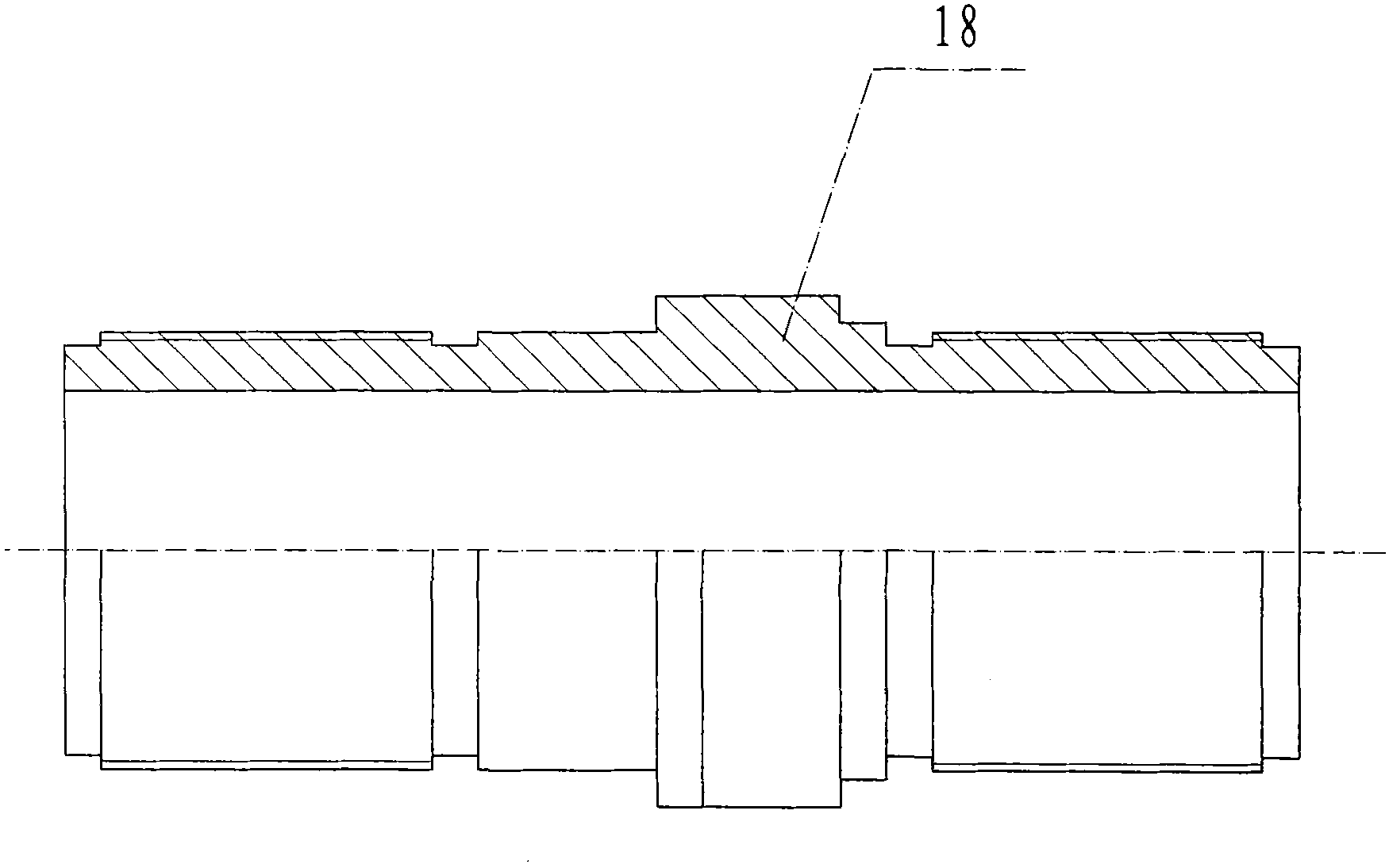

[0030] The plunger has at least two sections, and each section is screwed to each other through a plunger joint. As shown in the figure, the plunger shown in this embodiment is composed of 4 sections (in 2 groups). The structure of plunger body 13 is referring to figure 2 , plunger fitting 18 see image 3 , the two ports of the plunger body are provided with internal threads, and the two ports of the plunger joint are provided with external threads, and the middle section of the plunger joint forms a step with the two retracted port sections, and the pipe diameter of the middle se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com