an emulsion flocculant

An emulsifier and composition technology, applied in the field of emulsion flocculants and emulsifiers, can solve problems such as insufficient improvement of emulsion, and achieve the effects of low coagulation rate, improved stability and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

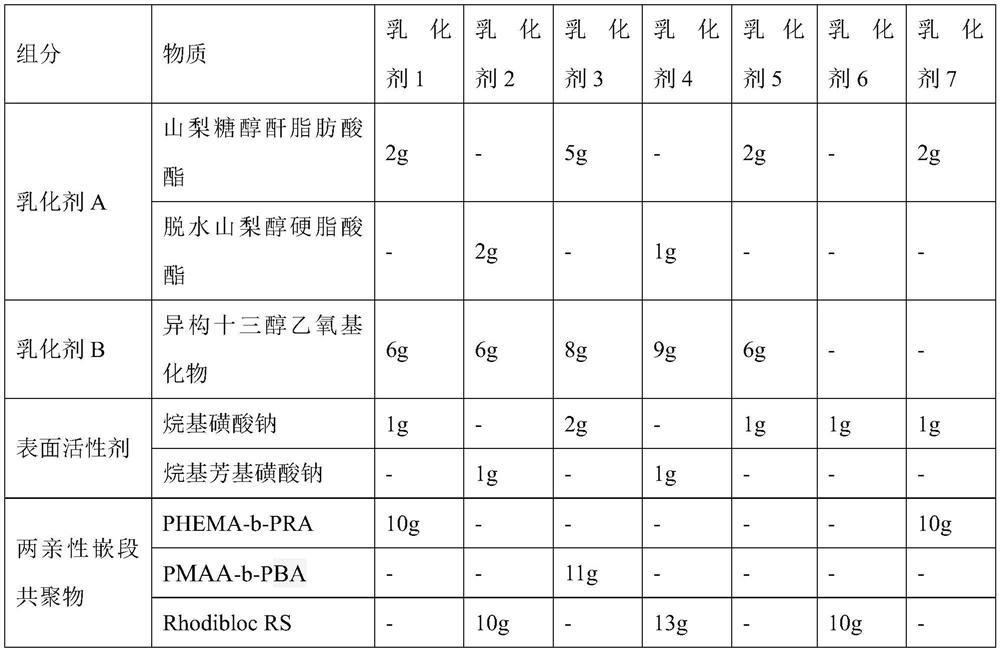

[0039] Embodiment 1, emulsifier composition

[0040] See Table 1 for the composition and dosage ratio of the emulsifier composition (emulsifier 1-4) that meets the requirements of this application and the emulsifier composition (emulsifier 5-6) as a comparison.

[0041] The composition and consumption table of each emulsifier composition of table 1

[0042]

[0043] As a control, emulsifier 8 contained only sodium alkylsulfonate.

[0044] Emulsifier 9 as a control contained only PHEMA-b-PRA.

Embodiment 2

[0045] Embodiment 2, the preparation of polyacrylamide emulsion

[0046] A kind of polyacrylamide emulsion, its preparation comprises the steps:

[0047] (1) Preparation of the water phase: dissolving acrylamide and sodium acrylate monomers in the water phase and adjusting the pH value to 6.8;

[0048] (2) Preparation of the oil phase: each emulsifier composition in Example 1 is mixed with the oil phase solvent;

[0049] (3) Preparation of monomer emulsion: control the maximum temperature of 30°C, the oil phase is sheared at 6400RPM at high speed for 60s, during which the water phase is slowly added to the oil phase;

[0050] (4) Emulsion polymerization: add a redox initiator to initiate the polymerization reaction, the polymerization temperature is 45°C, the highest polymerization temperature is 47°C, and the polymerization time is 45min;

[0051](5) Finished product: After the reaction, a reverse phase agent is added to obtain an anionic polyacrylamide emulsion. The emuls...

Embodiment 3

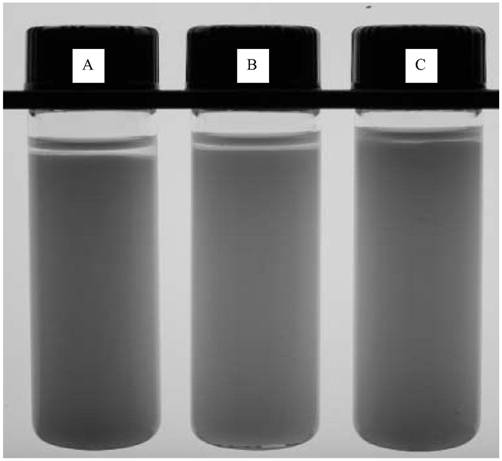

[0060] Embodiment 3, standing test at normal temperature

[0061] Emulsions 1-7 obtained in Example 2 were put into test tubes respectively, capped, and stored at room temperature and pressure for 6 weeks.

[0062] The results showed that emulsion 1-4 had no delamination phenomenon; emulsion 5 had serious delamination, emulsion 6 had delamination, and emulsion 7 had slight delamination. see results figure 2 . Wherein A is emulsion 5, B is emulsion 6, and C is emulsion 7.

[0063] Emulsions 1-7 were put into test tubes respectively, capped, and stored at room temperature and pressure for 6 months.

[0064] The results showed that emulsion 1-6 had no delamination phenomenon; emulsion 5-7 had severe delamination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com