Double-sided liquid cooling heat dissipation multi-channel comprehensive assembly

A liquid-cooled heat dissipation and multi-channel technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as difficulty in meeting the heat dissipation needs of components, cramped heat dissipation space, and electrical connector failures. Achieve the effect of improving heat dissipation and temperature uniformity performance, strong heat dissipation capacity, and low processing, manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further clearly and completely described below with reference to specific embodiments and accompanying drawings. It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

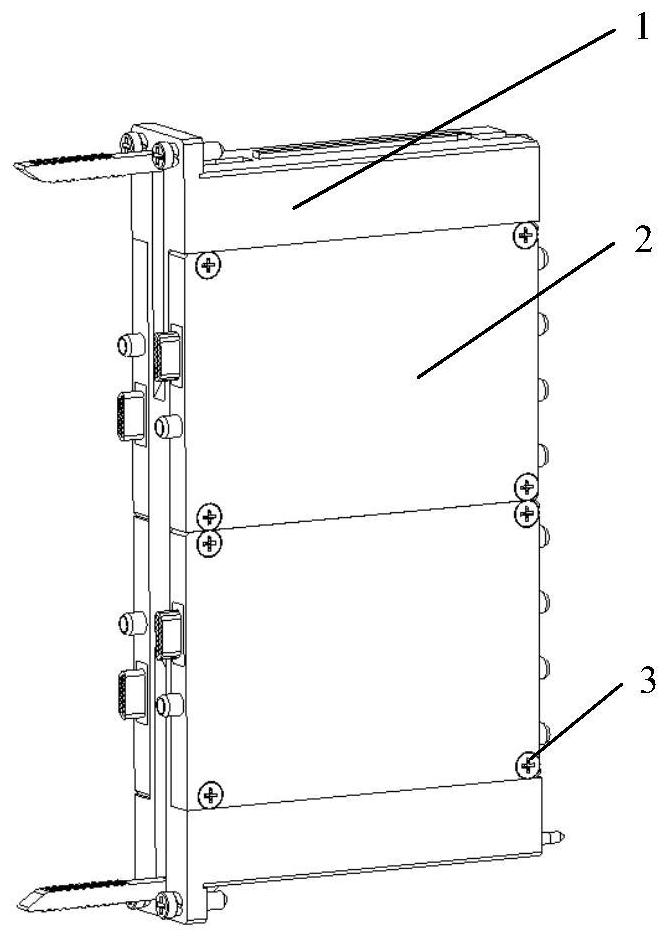

[0036] like figure 1 As shown, a multi-channel integrated assembly with double-sided liquid cooling and heat dissipation includes a liquid cooling plate 1 , a four-channel T / R assembly 2 , and mounting screws 3 . The liquid-cooling plate 1 is located in the middle of the multi-channel integrated assembly, and completes the functions of heat dissipation and overall external installation and connection. Two, complete the function of transmitting and receiving radio frequency signals.

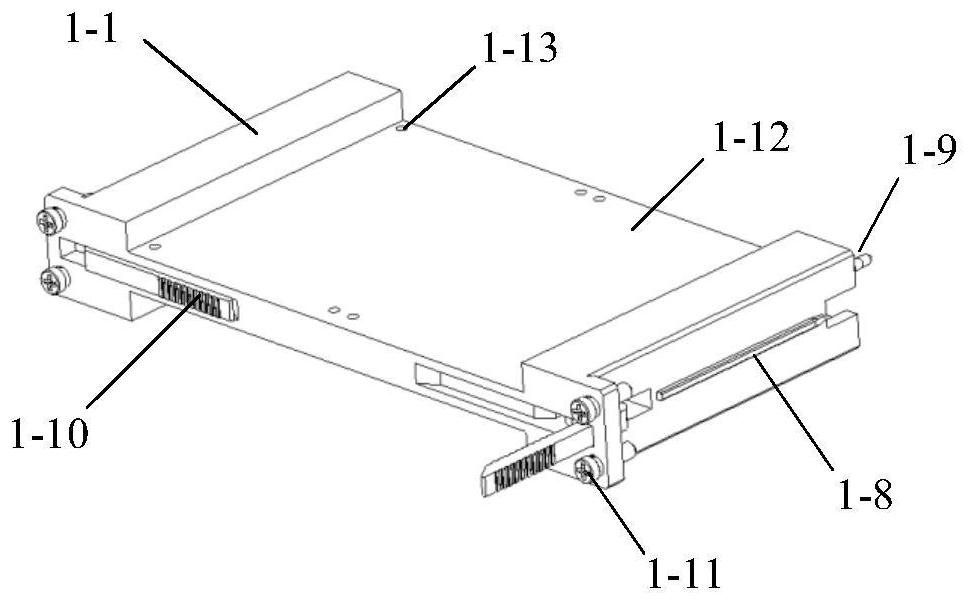

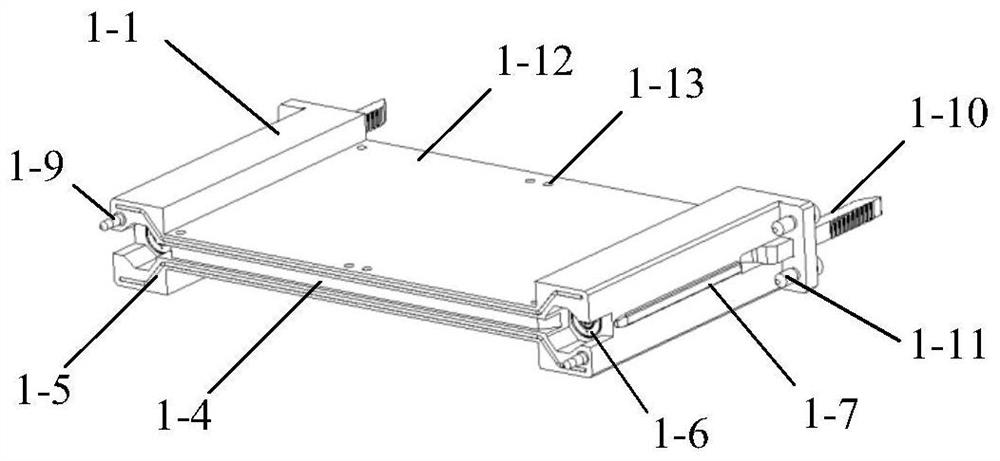

[0037] like figure 2 , image 3 , Figure 4 , Figure 5 As shown, the liquid cold plate 1 includes a cold plate shell 1-1, an S-shaped water channel 1-2, a heat conduction spoiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com