Steam generator with electrical heating power changing along with distance to center

A steam generator and electric heater technology, applied in the field of boilers, can solve the problems of uneven heating of steam generators, low steam efficiency, single heater structure, etc., to improve heating uniformity, heating efficiency, and uniform temperature distribution , Improve the effect of safety performance and heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

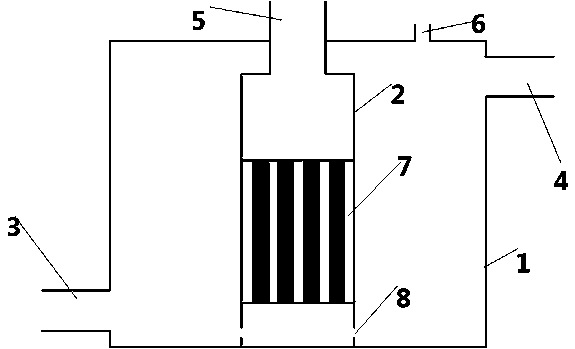

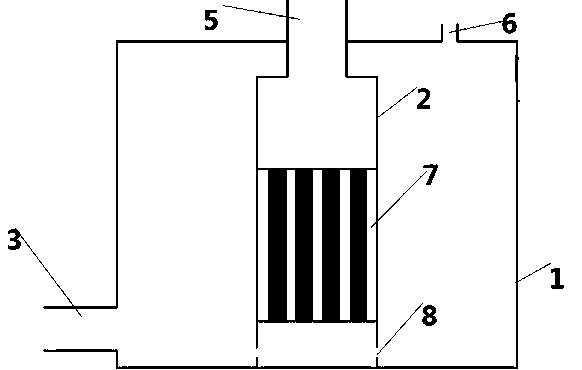

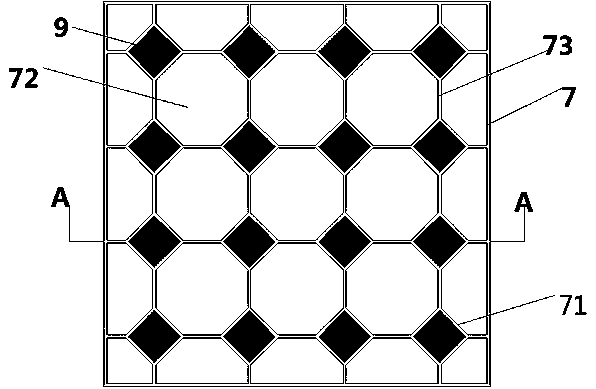

[0043] Figure 1-5 A steam generator is shown. like figure 1 As shown, the steam generator includes a box body 1, an inner pipe body 2, a cold water inlet 3, a hot water outlet 4 and a steam outlet 5, the cold water inlet 3 is arranged at the lower part of the box body 1, and the hot water outlet 4 Located on the top of the box body. The inner tube body 2 is arranged in the box, and the inner tube body 2 is arranged in a vertical direction (perpendicular to the bottom plane of the water tank), and the inner tube body 2 includes an outer tube and a core body 7 arranged in the outer tube. The lower part of the pipe body 2 is provided with a water inlet passage 8 to ensure that the water in the box body 1 can enter the inner pipe body 2 for heating, and the upper part of the inner pipe body 2 is connected to the steam outlet 5; the core body 7 is arranged on the upper part of the water inlet passage 8, so that The core body 7 extends in the vertical direction of the inner tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com