Built-in oil separator type water condenser

A technology of water condenser and oil separator, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of oil diversion, easy freezing and cracking of heat exchange tubes, unsatisfactory effect of oil and gas separation, etc. It can achieve the effect of convenient disassembly, preventing freezing and cracking of heat exchange tubes, and ensuring the effect of heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

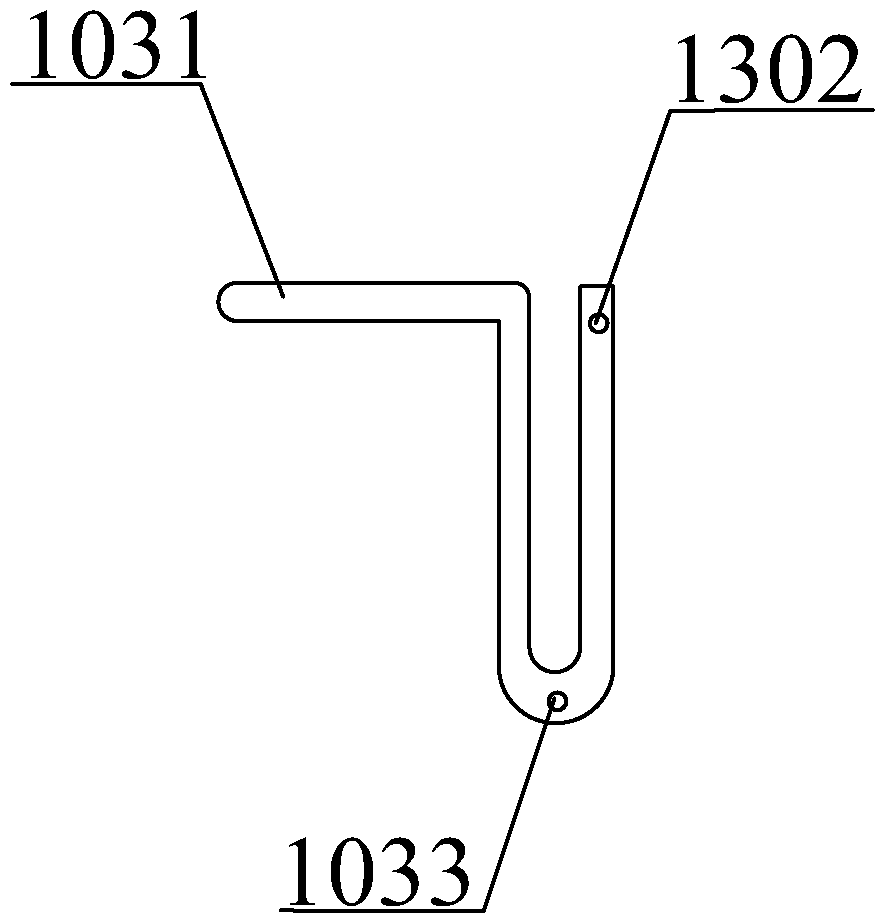

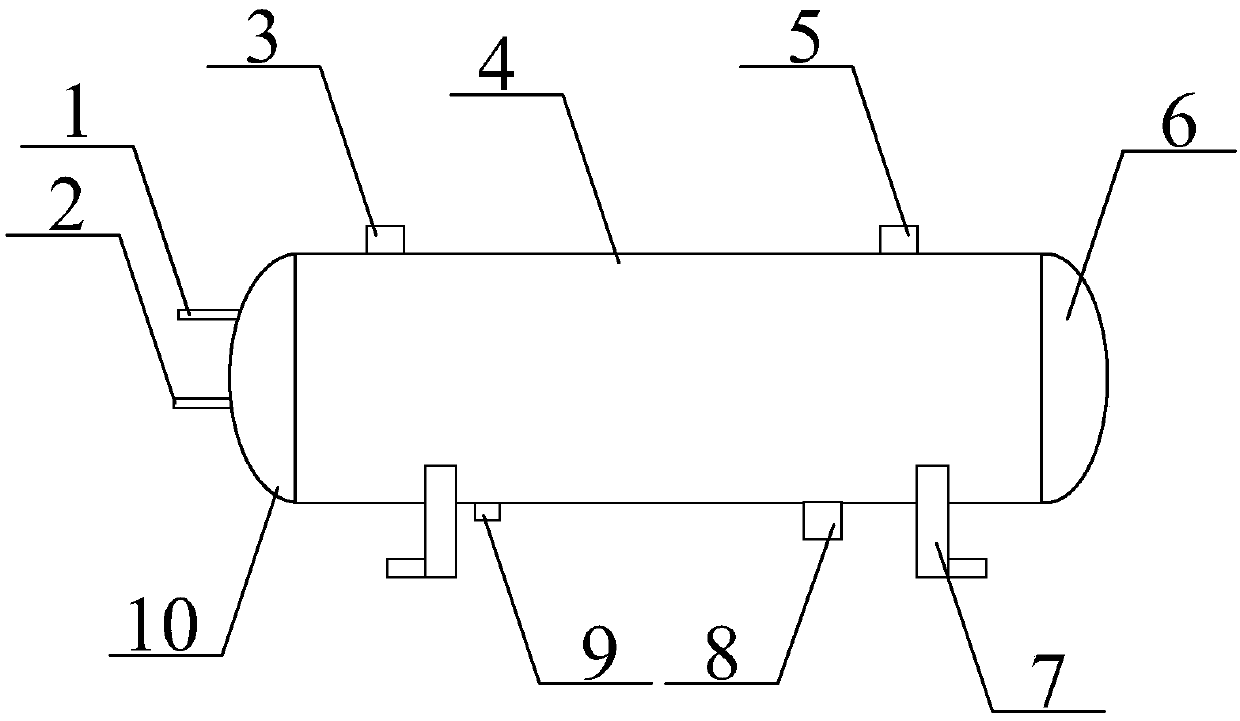

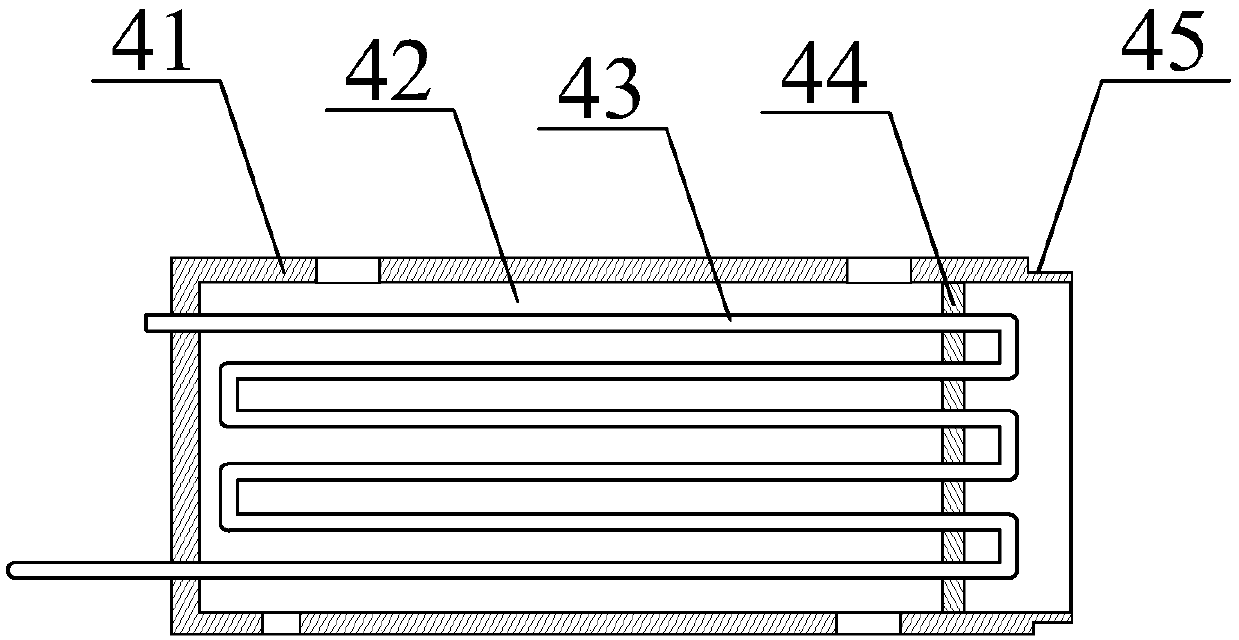

[0027] Such as Figure 1-4 As shown, the present invention provides a technical solution: a built-in oil separator type water condenser, including a condensing agent gas inlet, a condensing agent liquid outlet, a steam outlet, a condenser assembly, a condensed water inlet, a right end cover, and a bracket seat , the condensate outlet, the drain port and the oil-gas separation end, the condensate gas inlet and the condensate liquid outlet are sequentially opened on one side of the oil-gas separation end from top to bottom; the steam outlet is opened on the left end of the condenser assembly The upper part is connected with the heat exchange chamber; the condensed water inlet is set on the upper part of the right end of the condenser assembly and communicates with the heat exchange chamber; the right end cover is connected with the right end of the condenser assembly through threads; the bracket Two seats are used, both of which are welded at the bottom of the condenser assembly...

Embodiment 2

[0029] A built-in oil separator type water condenser, including condensing agent gas inlet, condensing agent liquid outlet, steam outlet, condenser assembly, condensed water inlet, right end cover, bracket seat, condensed water outlet, drain port and oil-gas separation end The condensing agent gas inlet and the condensing agent liquid outlet are sequentially opened on one side of the oil-gas separation end from top to bottom; the steam outlet is opened on the upper part of the left end of the condenser assembly and communicates with the heat exchange chamber; The condensed water inlet is set on the upper part of the right end of the condenser assembly, and is connected with the heat exchange chamber; the right end cover is connected with the right end of the condenser assembly through threads; the support seat adopts 2 pieces, which are welded on the condenser assembly The bottom of the condenser; the condensed water outlet and the drain are set at the bottom of the condenser a...

Embodiment 3

[0032] A built-in oil separator type water condenser, including condensing agent gas inlet, condensing agent liquid outlet, steam outlet, condenser assembly, condensed water inlet, right end cover, bracket seat, condensed water outlet, drain port and oil-gas separation end The condensing agent gas inlet and the condensing agent liquid outlet are sequentially opened on one side of the oil-gas separation end from top to bottom; the steam outlet is opened on the upper part of the left end of the condenser assembly and communicates with the heat exchange chamber; The condensed water inlet is set on the upper part of the right end of the condenser assembly, and is connected with the heat exchange chamber; the right end cover is connected with the right end of the condenser assembly through threads; the support seat adopts 2 pieces, which are welded on the condenser assembly The bottom of the condenser; the condensed water outlet and the drain are set at the bottom of the condenser a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com