Pipeline magnetic flux leakage detecting data automatic analysis system

An automatic analysis system and magnetic flux leakage detection technology, applied in the direction of material magnetic variables, etc., can solve the problems of time-consuming, etc., and achieve the effect of intuitive result display and flexible deployment mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

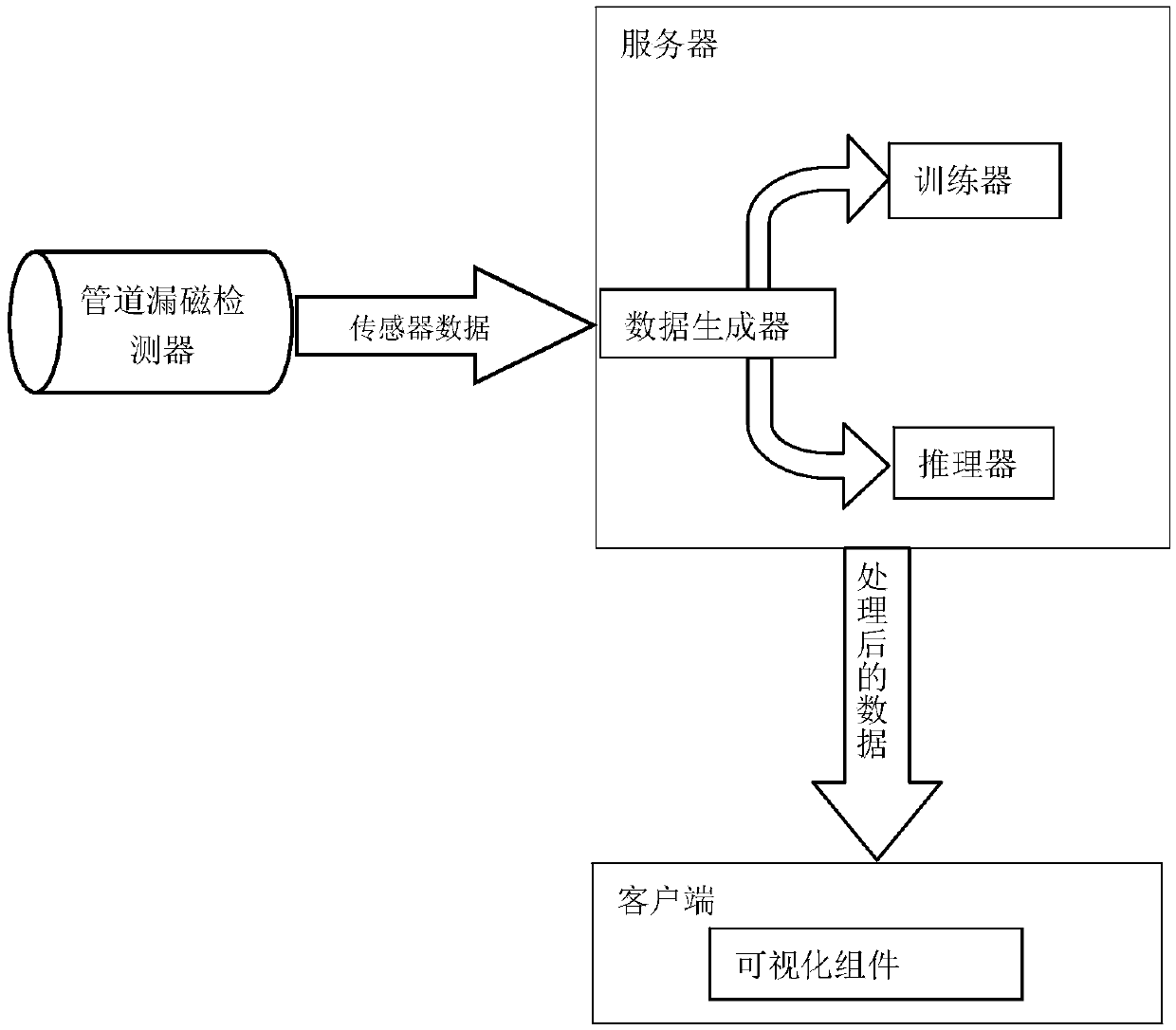

[0027] image 3 It is a typical deployment mode of the present invention. The pipeline magnetic flux leakage detector of the present invention firstly collects the magnetic flux leakage data of the detected pipeline, and transmits the data to the data generator deployed on the server. Transmission methods include but are not limited to online network transmission methods such as RS232, RS485, parallel port transmission, Ethernet cable, and wireless network, as well as transmission methods via physical storage media such as SD cards, flash disks, and hard disks. After receiving the original data, the data generator performs data loading (to memory), data cleaning (checking format, denoising according to predetermined rules), data conversion (alignment of sensor serial number, alignment of position signal, calibration of mileage information, X, Y, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com