A kind of wide temperature infrared lens, its installation and adjustment tool and its installation and adjustment method

A technology of infrared lens and tooling, which is applied in the field of infrared lens, can solve the problems of affecting imaging quality, large cumulative error, and limitation, and achieve the effect of ensuring imaging quality, high hardness, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

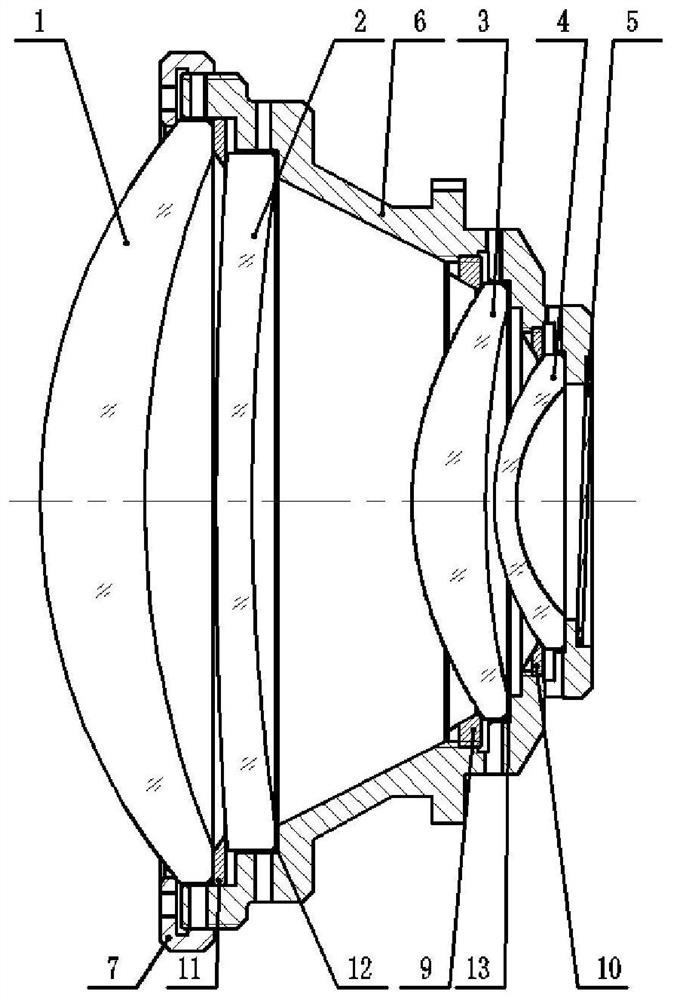

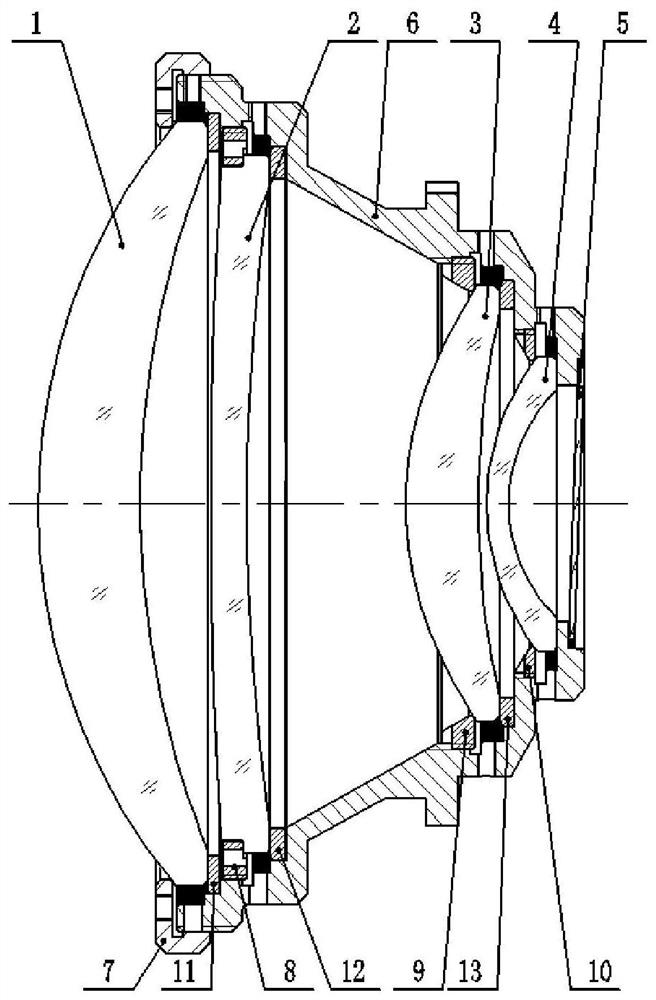

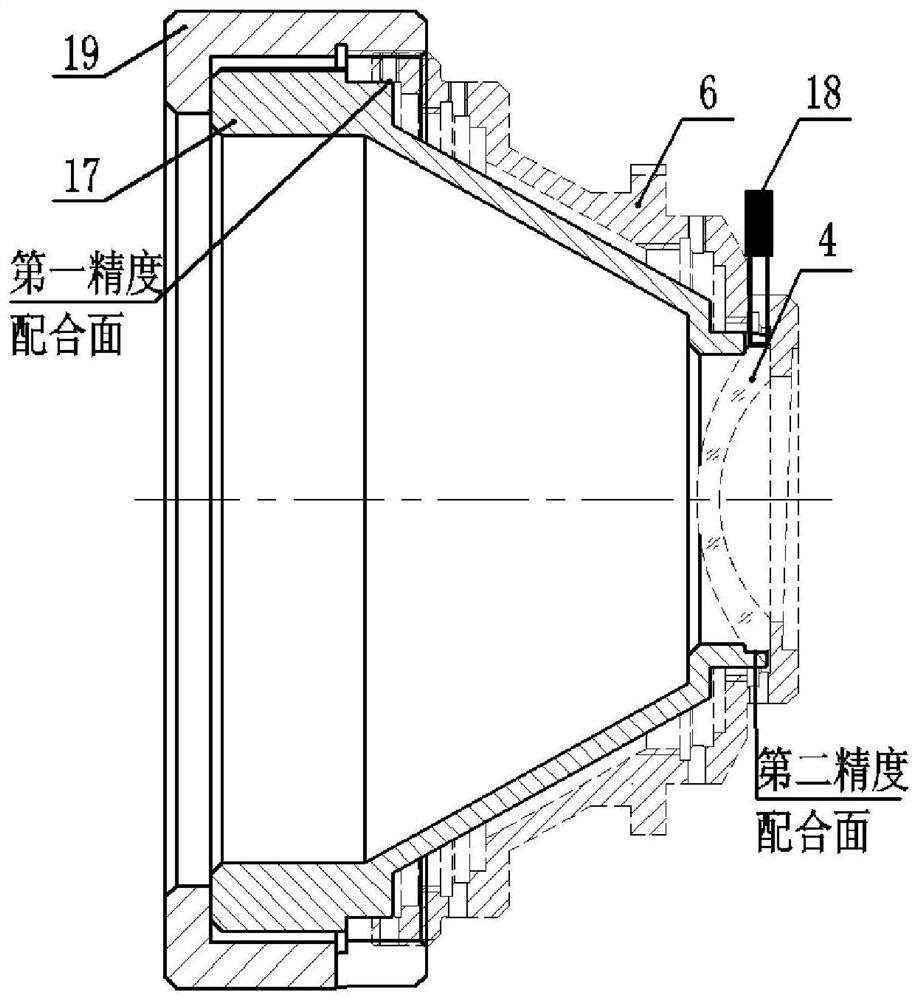

[0054] Such as figure 2 As shown, a wide temperature infrared lens includes a first lens 1, a second lens 2, a third lens 3, a fourth lens 4, a filter 5, a lens barrel 6, a first pressure ring 7, a second pressure ring 8, The third pressure ring 9, the fourth pressure ring 10, the first adjustment pad 11, the second adjustment pad 12 and the third adjustment pad 13;

[0055] The lens barrel 6 is a hollow circular platform structure with both ends open, and the inner wall of the lens barrel 6 is processed with a stepped surface for installing four lenses, and the circumference of the axial lens barrel 6 that constitutes the stepped surface is processed with screw adjustment holes and injection Glue exhaust hole, the outer wall of lens barrel 6 big mouth end is processed with screw thread;

[0056] The first pressure ring 7 is a ring structure, one end is processed with a positioning ring surface in the radial direction, and the inner wall of the other end is processed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com