Processing device and processing method of quick-frozen processed crayfish product

A processing equipment and lobster technology, which is applied in the field of crayfish quick-frozen conditioning products processing equipment, can solve the problems of less automatic processing equipment for crayfish, slow deep processing of crayfish, and slow production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

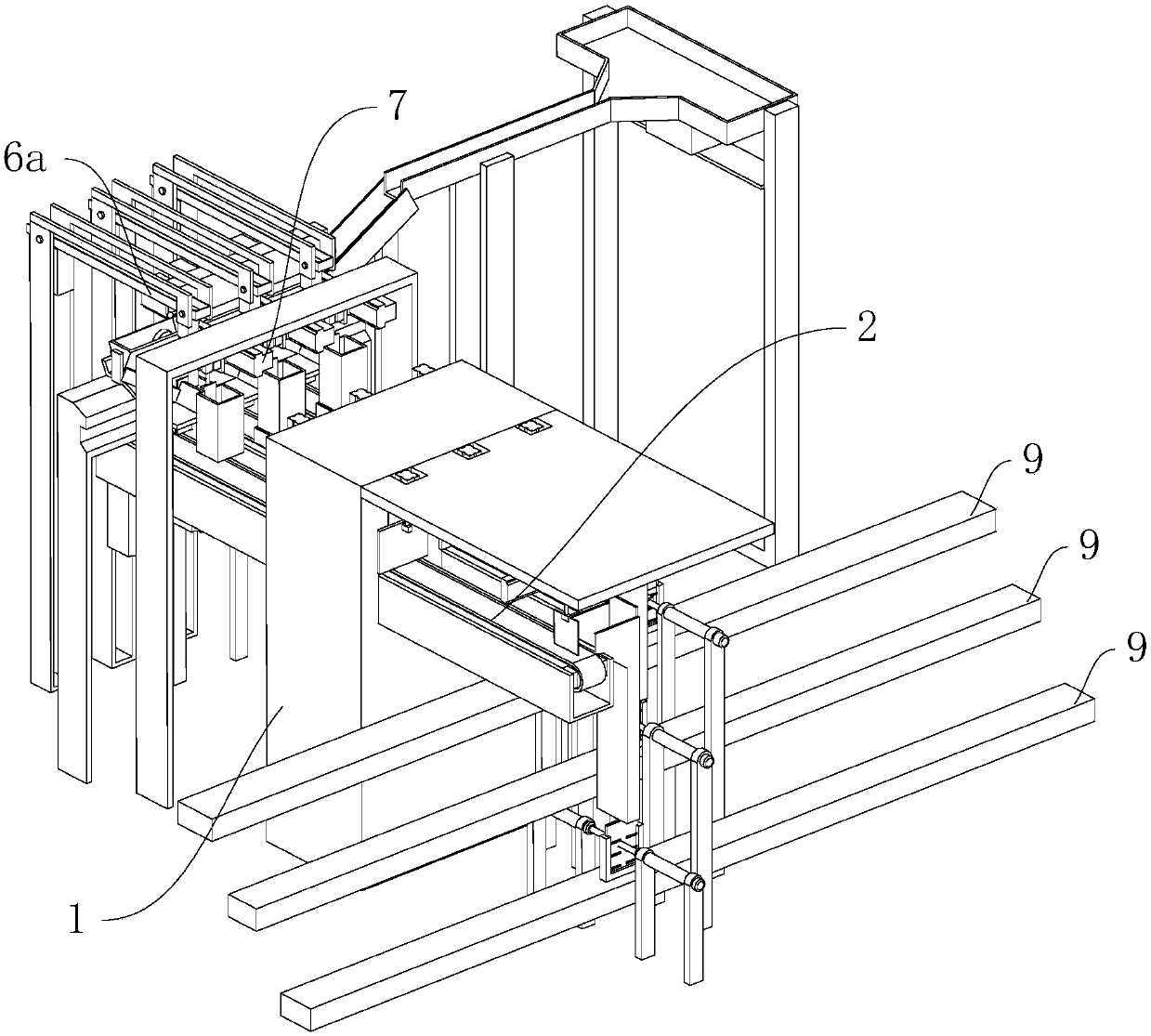

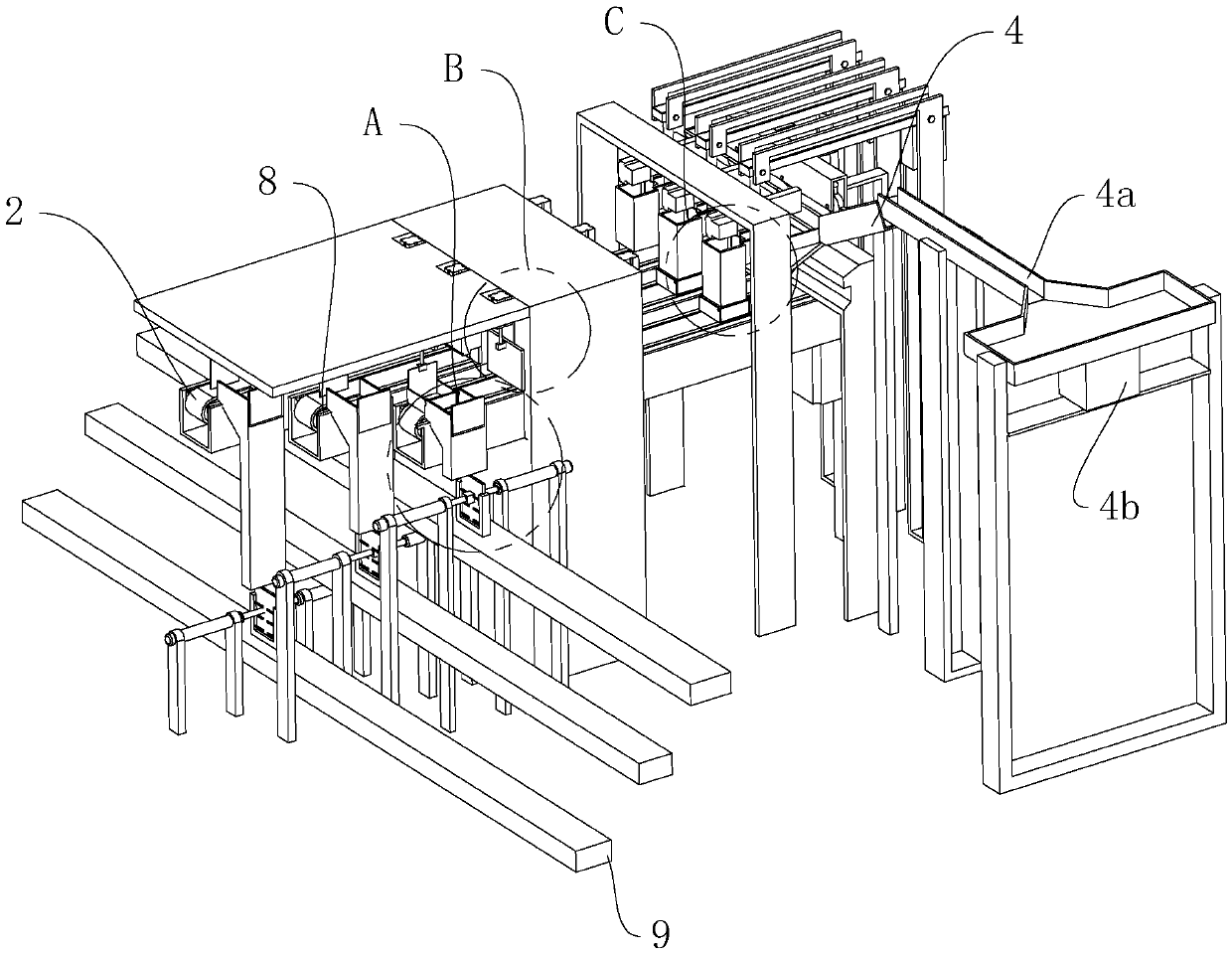

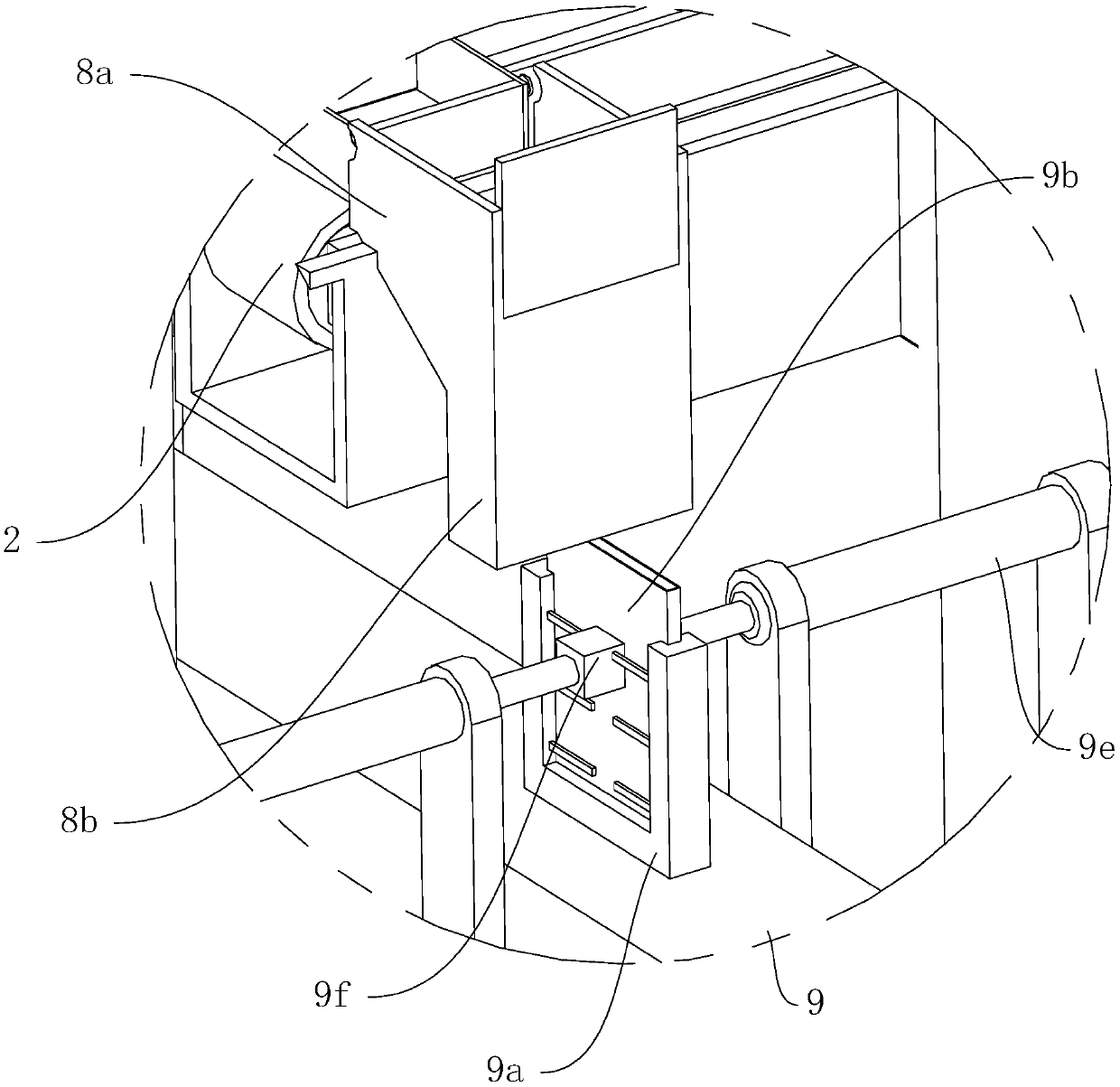

[0048] refer to Figure 1 to Figure 15 A crayfish quick-frozen conditioning product processing equipment shown includes a control cabinet, a screening device, a freezing bin 1, a discharge device, and at least three transfer conveyor belts 2 arranged at equal intervals along a straight line. All transfer conveyor belts 2 The conveying directions are parallel to each other. There are three channels on the outside of the freezer 1, which are respectively used for a transfer conveyor belt 2 to pass through it in a horizontal posture. The freezer 1 is provided with three inverted nitrogen nozzles 1c. Each nitrogen nozzle 1c corresponds to a transfer conveyor belt 2, and the freezer 1 is erected in the middle section of the transfer conveyor belt 2. Each transfer conveyor belt 2 is provided with a number of holding fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com