Intelligent dedusting equipment in chemical industry production

A technology for dust removal equipment and chemical production, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc. It can solve the problems of lack of self-purification mechanism in dust removal equipment, affect the service life of cloth bags, and affect the effect of dust removal, etc., and achieve compact structure , small footprint, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

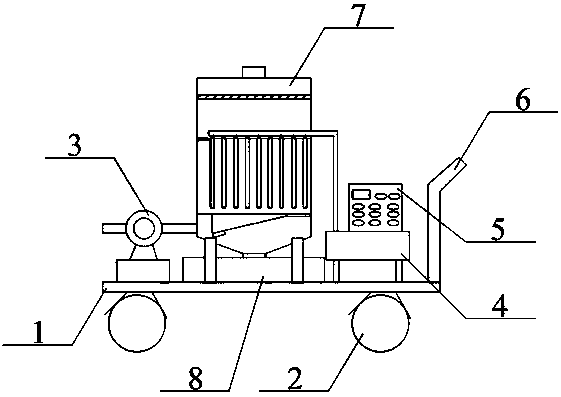

[0026] as attached figure 1 to attach Figure 5 shown

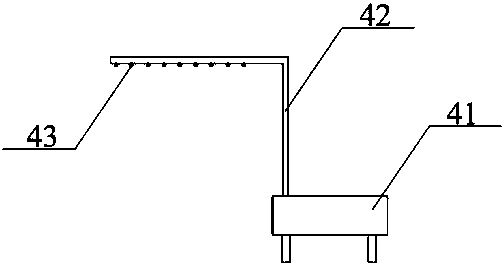

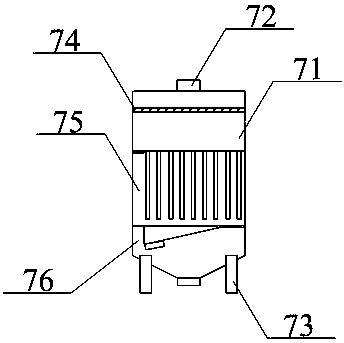

[0027] The present invention provides a kind of intelligent dedusting equipment in chemical production, comprising a base 1, a universal wheel 2, an exhaust fan 3, a self-purification mechanism 4, an electrical control cabinet 5, a handle 6, a dust removal mechanism 7 and a dust collection box 8, the described Four universal wheels 2 are used and fixed on the lower four corners of the base 1 by bolts; the handle 6 is welded on the right side above the base 1; the self-purifying mechanism 4 is fixed on the top of the base 1 by bolts 6; the electrical control cabinet 5 is fixed on the top of the air compressor 41 by bolts; the dust removal mechanism 7 is fixed on the middle position above the base 1 by bolts; the dust collection box 8 is fixed by bolts Above the base 1, below the dust removal mechanism 7, connected to the dust outlet 762 through a pipeline; the exhaust fan 3 is fixed on the left side above the base 1 by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com